Sheet discharging apparatus

a discharging apparatus and discharging tube technology, applied in the direction of transportation and packaging, instruments, photosensitive materials, etc., can solve the problems of high cost, easy breakage of one-way clutches, and difficult low production cos

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

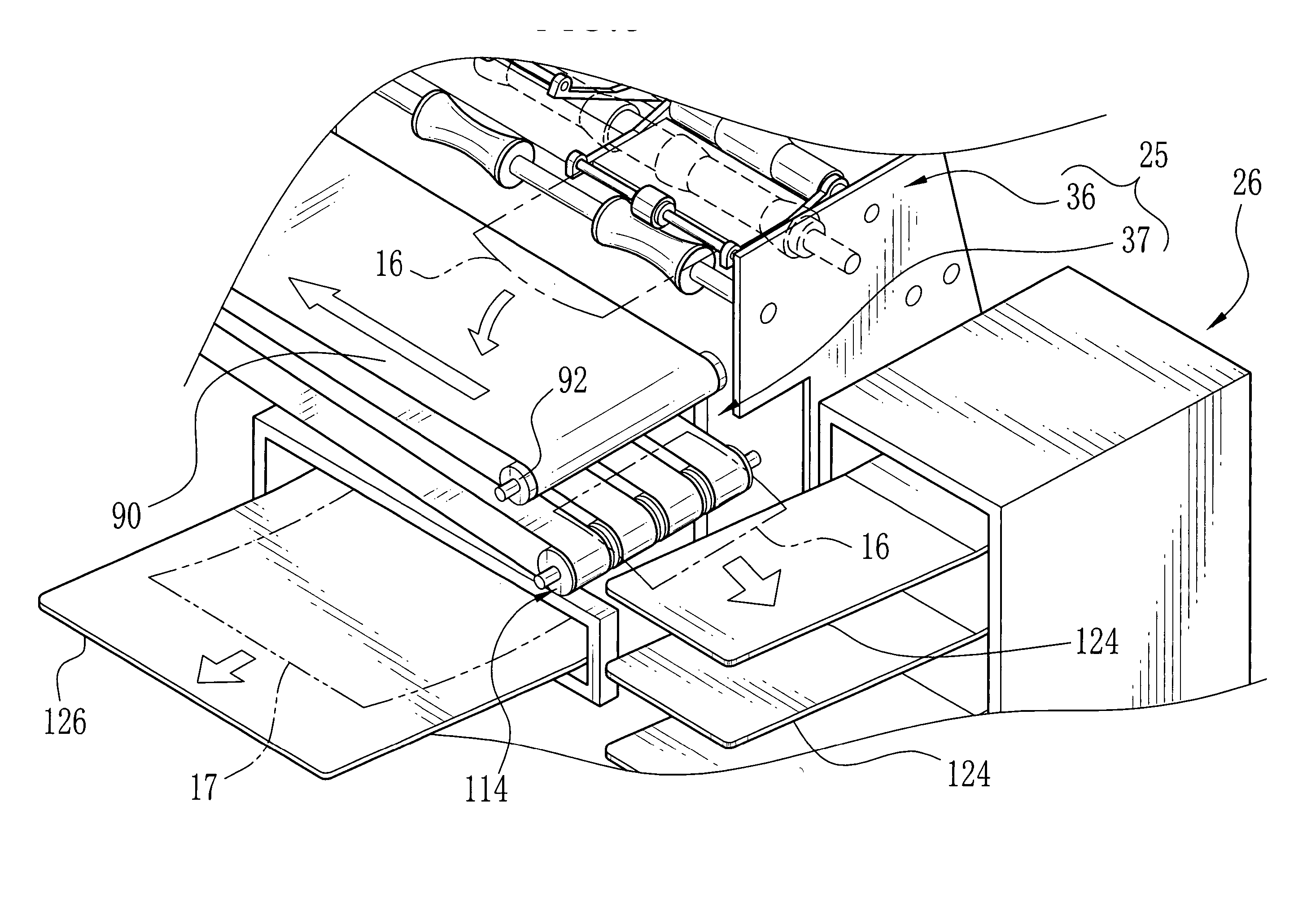

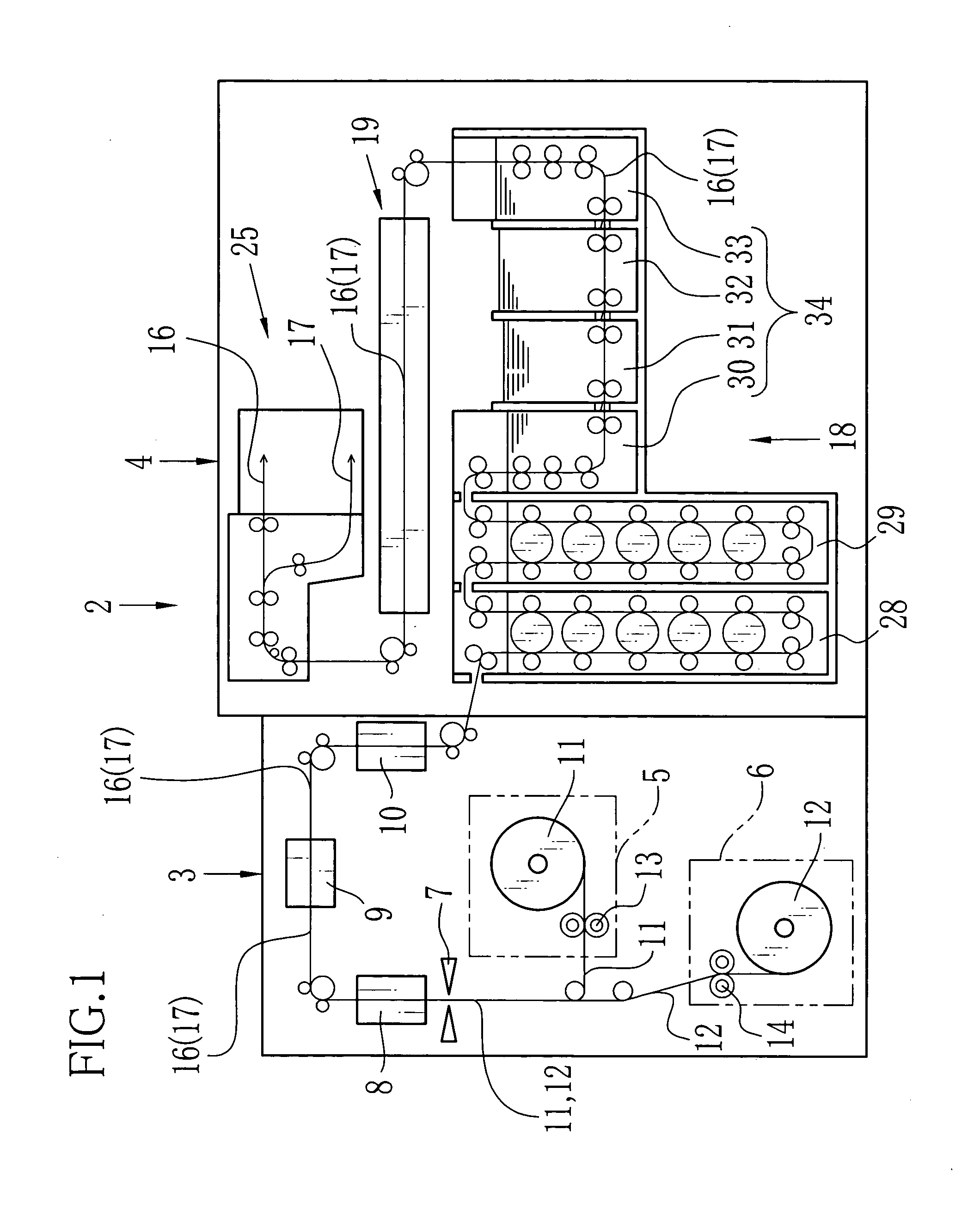

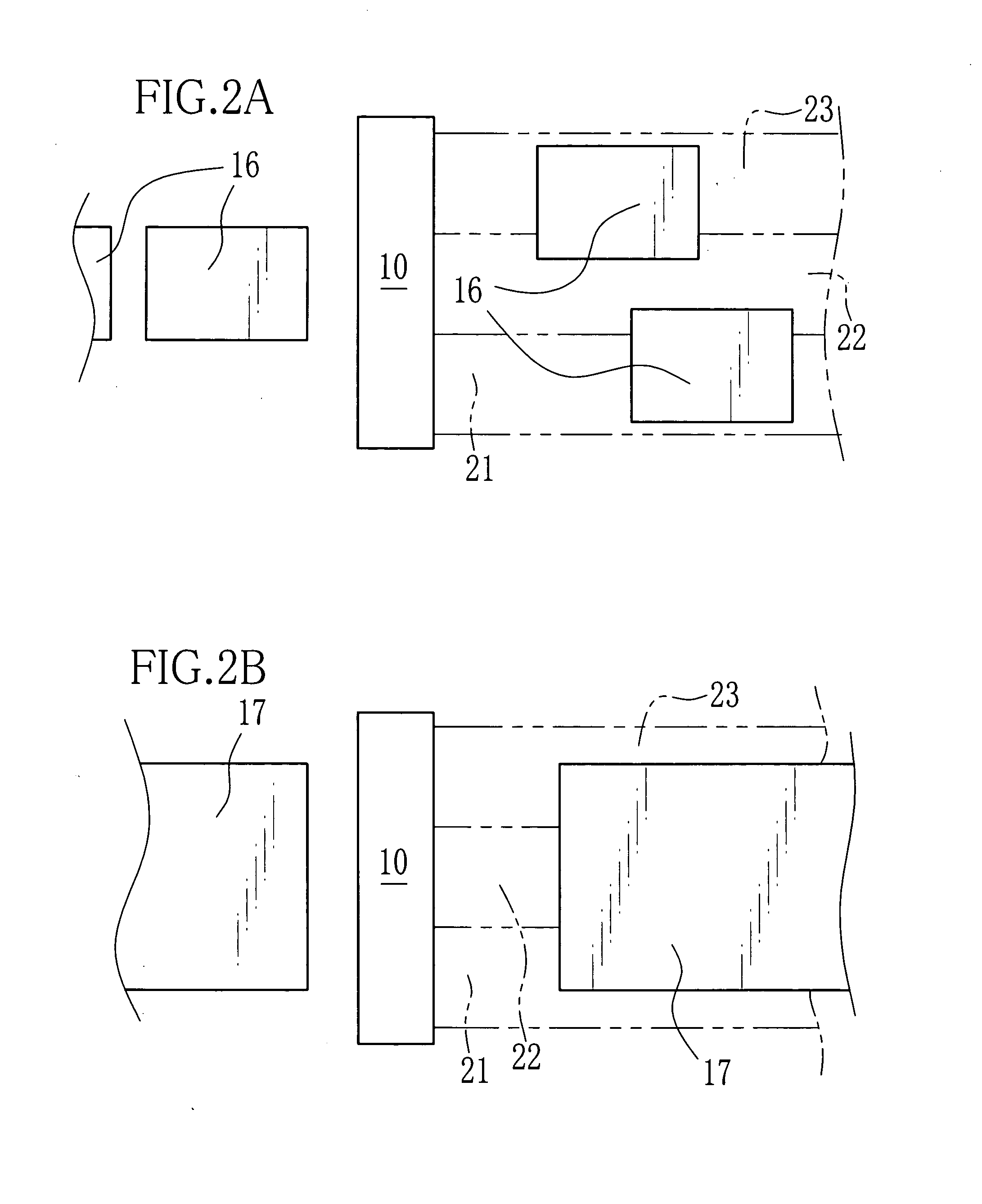

[0032] As shown in FIG. 1, a printer processor 2 is constructed of a printer section 3 and a processor section 4. The printer section 3 is constructed of magazines 5, 6, a cutter 7, a back printer 8, an exposure device 9, and a sheet dispenser 10. The magazines 5, 6 respectively contain rolls of color photographic papers (hereinafter, papers) 11, 12 having different width. When a feed roller 13 rotates, the paper 11 is drawn from the magazine 5, and the cutter 7 cuts the paper 11 in accordance with a print size to obtain a cut sheet paper, for example, an L-size sheet (width 89 mm.times.length 127 mm), a 2L-size sheet (width 127 mm.times.length 178 mm). When a feed roller 14 rotates, the paper 12 is drawn from the magazine 6, and the cutter 7 cuts the paper 12 in accordance with a print size to obtain the cut sheet paper, for example, an A4-size sheet (width 210 mm.times.length 297 mm). Usually, when an order of the printing is made in the photofinisher, one of the print sizes of th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Weight | aaaaa | aaaaa |

| Speed | aaaaa | aaaaa |

| Shape | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com