Offset pallet-rack safety net system

a safety net and pallet rack technology, applied in the field of material handling systems, can solve the problems of poorly stacked items coming down, affecting the safety of people below, and presenting a significant and not-so-rare personal injury risk in racks and shelves, and achieve the effect of simple operation and easy installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

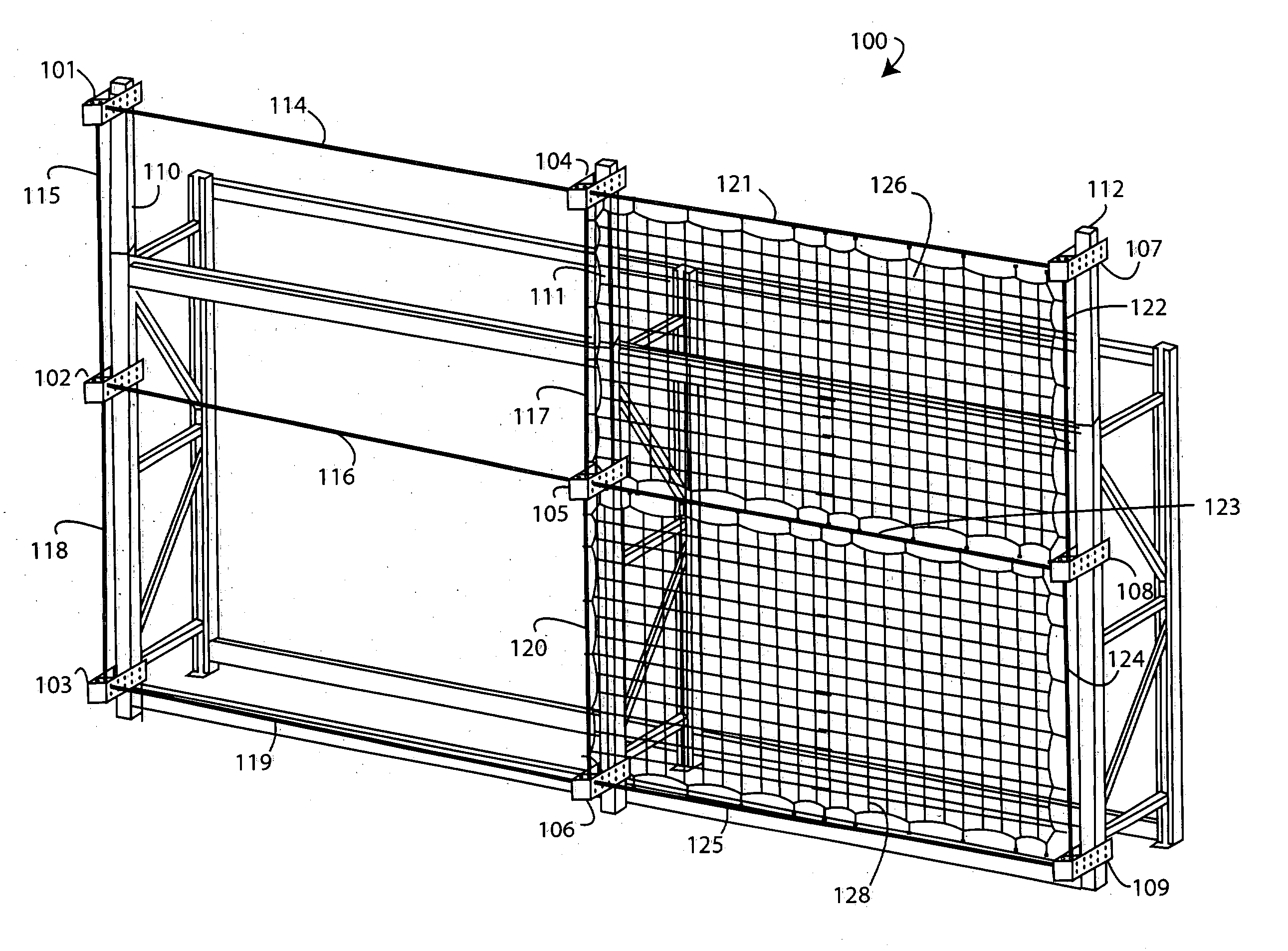

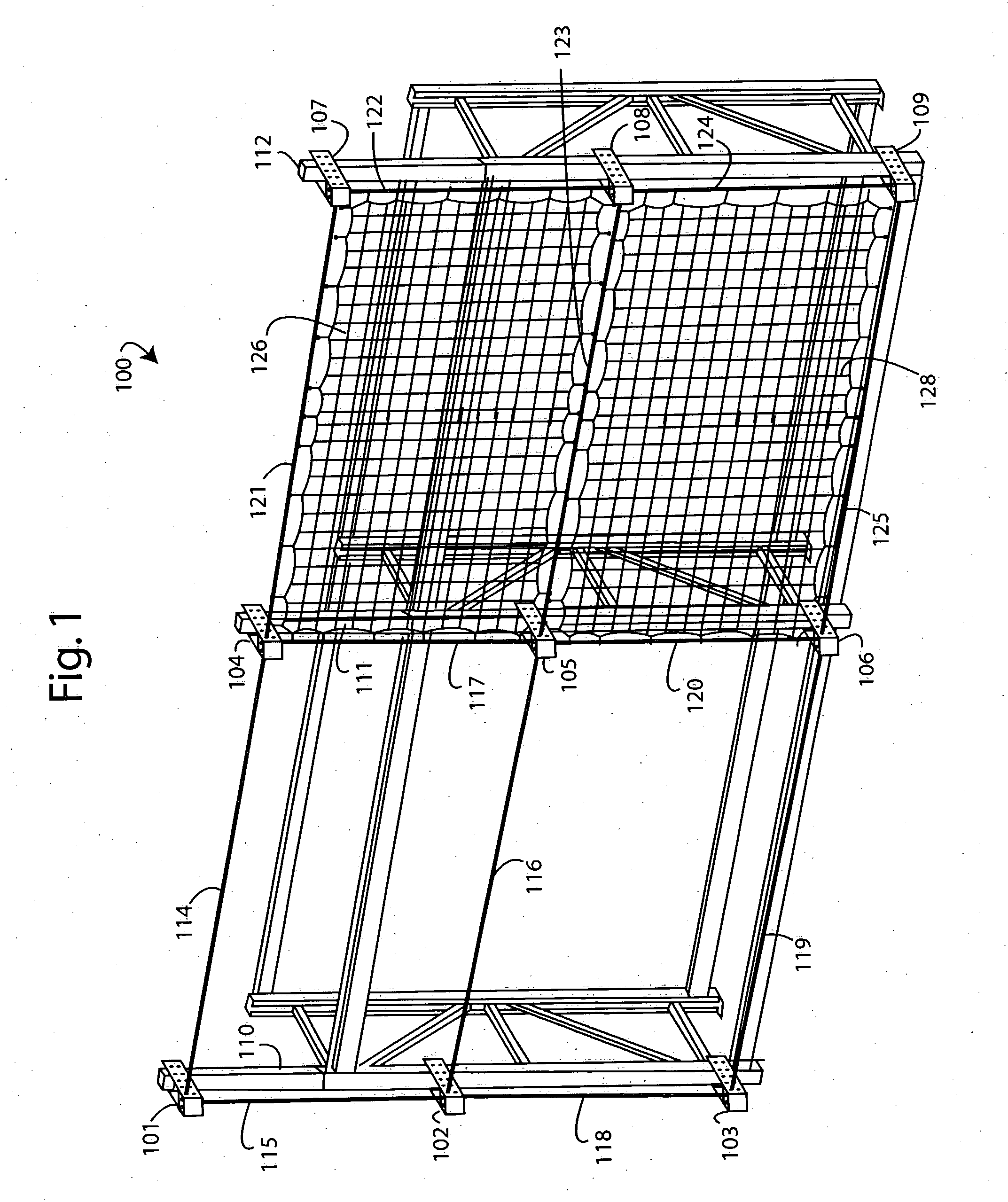

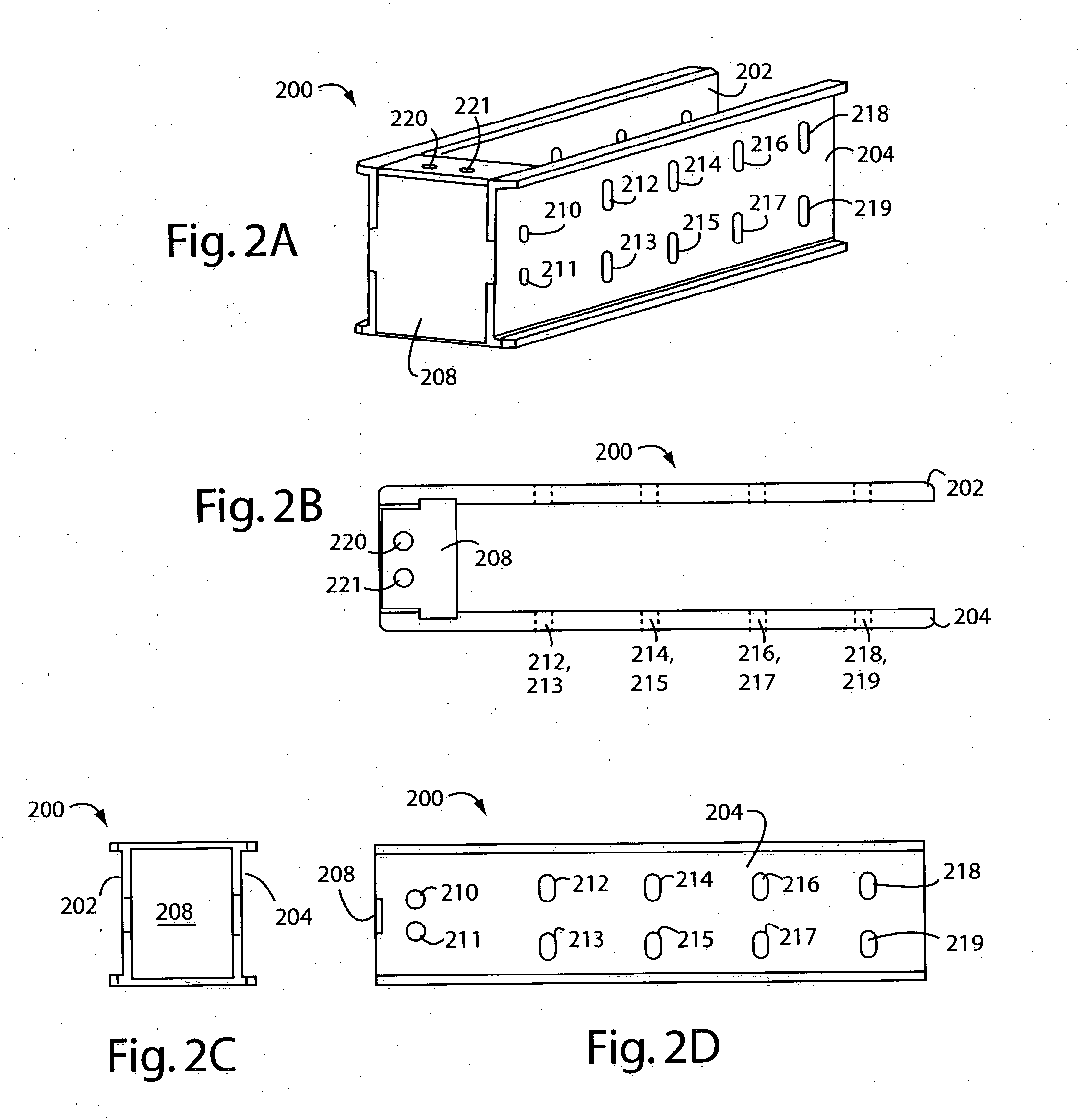

[0019]FIG. 1 illustrates a pallet-rack safety-netting system embodiment of the present invention, referred to herein by the reference numeral 100. The pallet-rack safety-netting system 100 comprises a number of extension brackets 101-109 that are bolted to three respective pallet rack vertical frame sections 110-112. A set of suspension cables 114-125 are strung taut between the offset brackets 101-109 and support safety nets at their perimeters. For example, a safety net 126 is suspended away from the pallet rack framing by vertical cables 117 and 122, and horizontal cables 121 and 123; and a safety net 128 is suspended between vertical cables 120 and 124, and horizontal cables 123 and 125. The nets can be attached to the cables every few inches by nylon cable ties or metal snap-hooks.

[0020] Embodiments of the present invention permit the safety nets to be positioned at a variety of clearances from the face of the pallet rack framing. Such clearance is needed when the pallets load...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com