Device having a pulsation reducing structure, a passage forming body and compressor

a technology of pulsation reducing structure and compressor, which is applied in the direction of positive displacement liquid engine, piston pump, liquid fuel engine, etc., can solve the problems of difficult to reduce the inner diameter of the cylindrical member to obtain and generate great pressure loss, etc., to suppress pressure loss, reduce structure, and achieve sufficient pulsation reducing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

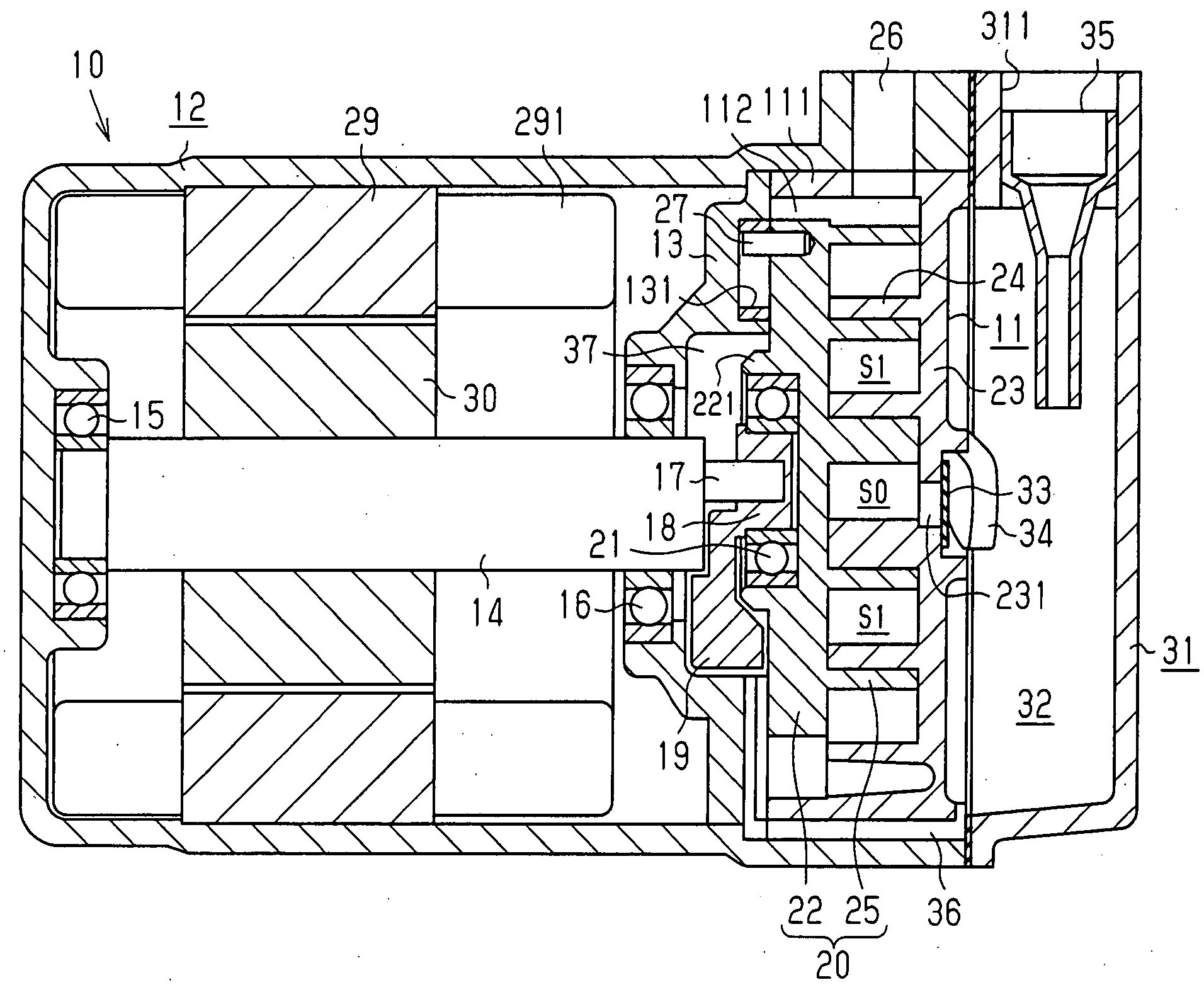

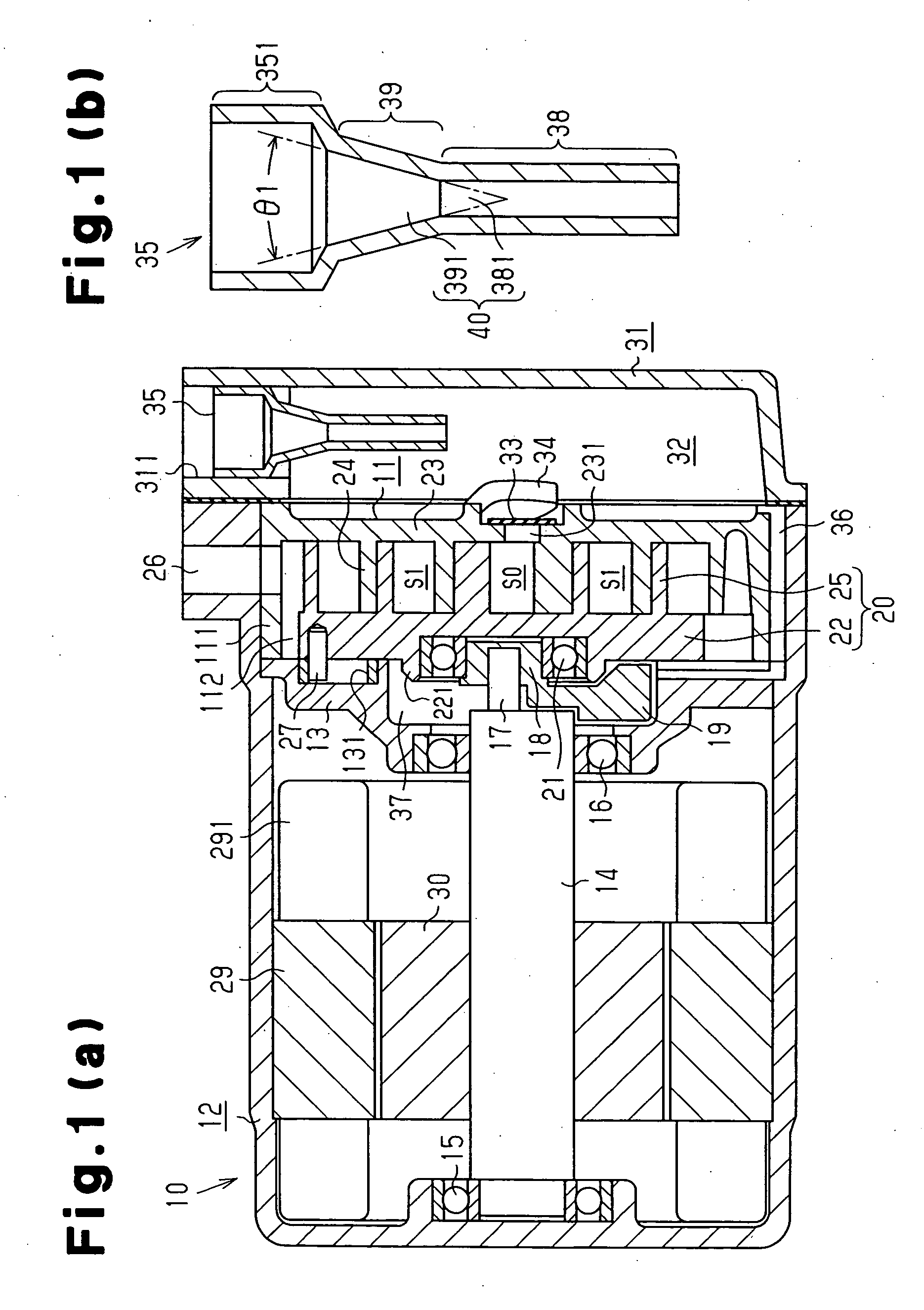

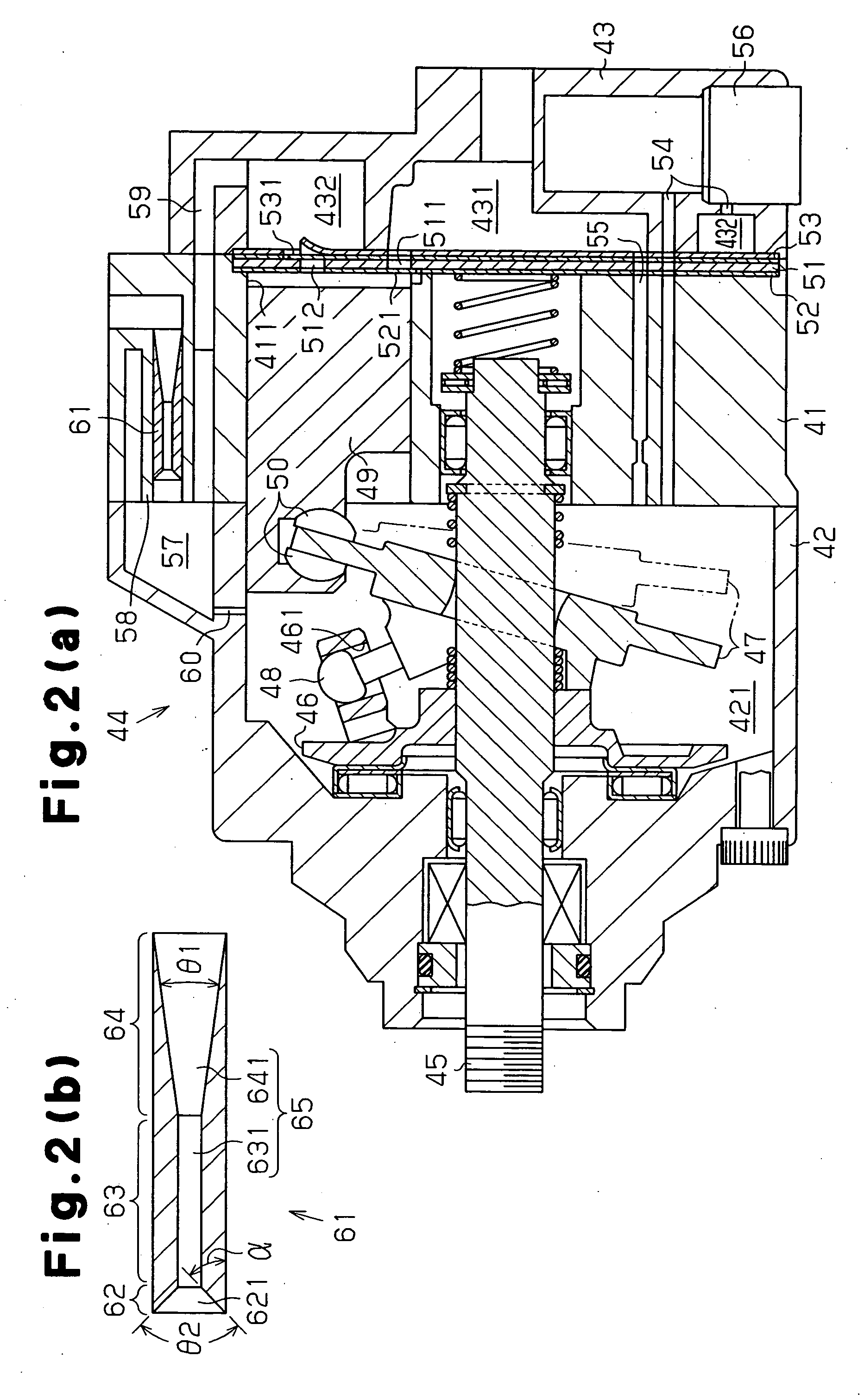

[0021] the present invention will now be described with reference to FIGS. 1(a) and 1(b).

[0022] As shown in FIG. 1(a), a scroll compressor 10 includes a rear housing member 12 and a front housing member 31. A shaft support member 13 and a fixed scroll 11 are inserted in and fixed to the rear housing member 12. The front housing member 31 is secured to the rear housing member 12 and the fixed scroll 11. The rear housing member 12 and the front housing member 31 form a housing of a device, which is the scroll compressor 10. The rear housing member 12 and the shaft support member 13 rotatably support a rotary shaft 14 by means of radial bearings 15, 16.

[0023] The rotary shaft 14 extends through the shaft support member 13 and projects toward the fixed scroll 11. An eccentric shaft 17 is formed integrally with the end of the rotary shaft 14 that projects from the shaft support member 13. The axis of the eccentric shaft 17 located at a position decentered from the axis of the rotary sha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com