Heat exchanger useful as charge-air cooler for commercial vehicles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

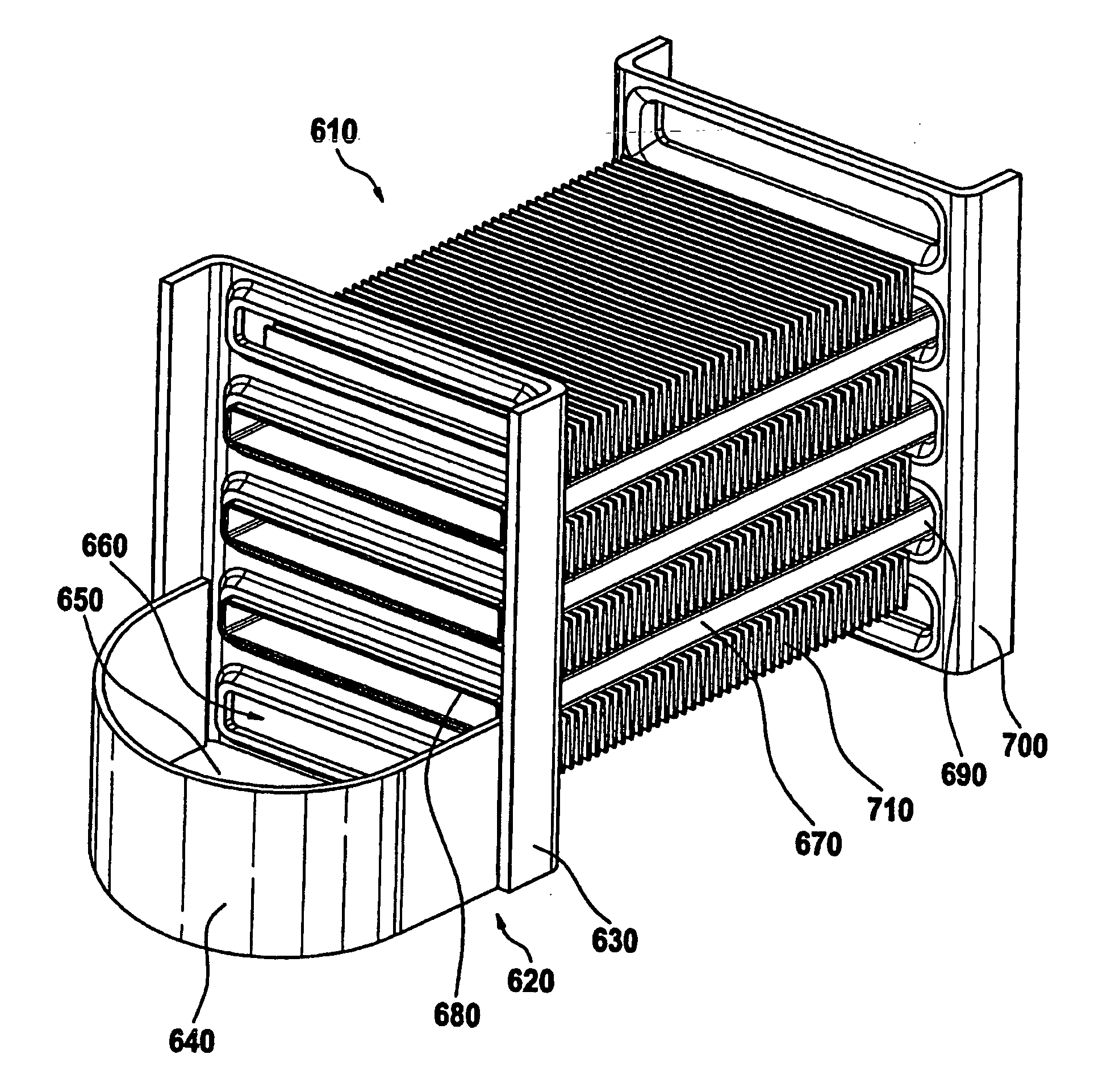

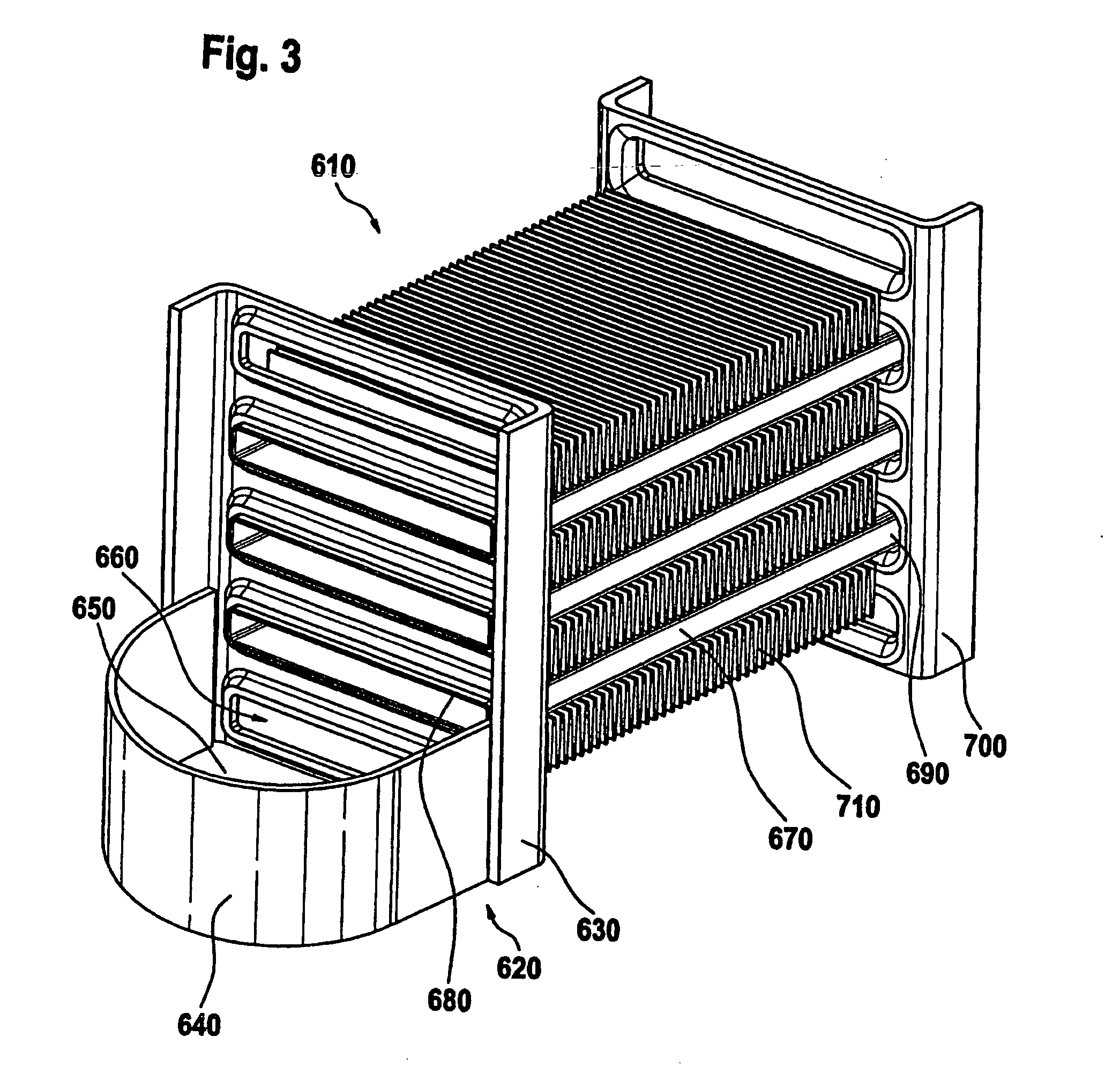

Image

Examples

Embodiment Construction

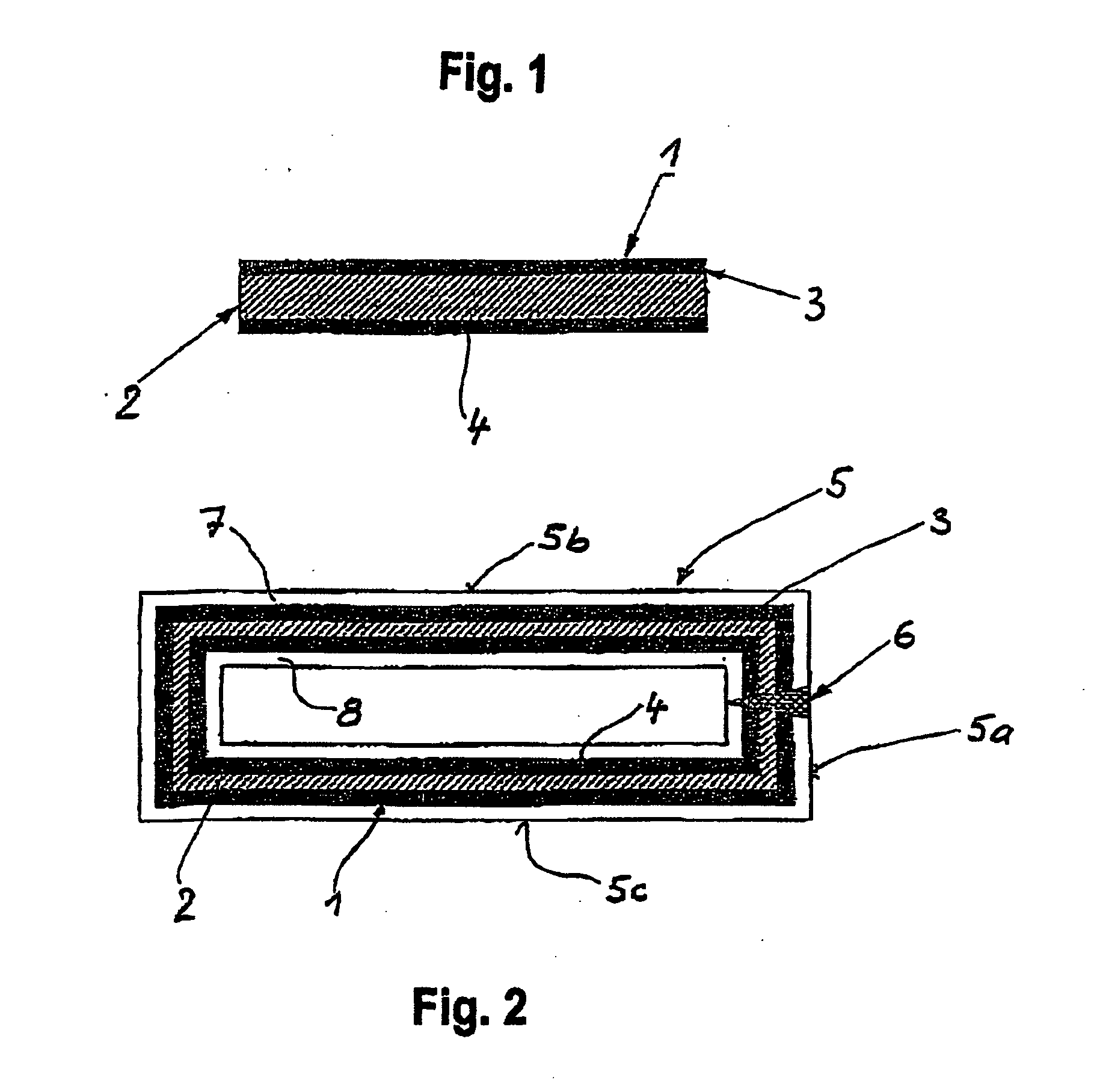

[0012] According to the invention, the tubes, header plates, collector tanks and / or turbulence plates of the heat exchanger are made from a steel strip which is clad or coated with aluminum on one or both sides. The core material of the tube therefore consists of steel, i.e., a high-strength material which retains its strength even at relatively high temperatures. One or both outer sides of the steel strip are provided with a layer of aluminum which, on the one hand, protects the core material from corrosion and, on the other hand, allows the tubes to be brazed to the fins and to the header plate. This improvement to the strength and, in particular, the hot strength of the tube material is virtually neutral in terms of weight, i.e., does not result in a greater tube weight compared to aluminum tubes of greater wall thickness.

[0013] The term “tubes” is in general to be understood as meaning flow passages which can be produced from the aluminum-clad steel strip according to the inven...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fraction | aaaaa | aaaaa |

| Fraction | aaaaa | aaaaa |

| Time | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com