Locomotive draft gear assembly and yoke

a technology of gear assembly and locomotive, which is applied in the direction of railcar coupling accessories, draw-gear, railway components, etc., can solve the problems of increasing the speed difference between the railcars, severe impact on the coupler of the awaiting car, and increasing the impact of buff and draft on the couplers, so as to achieve the effect of light weigh

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

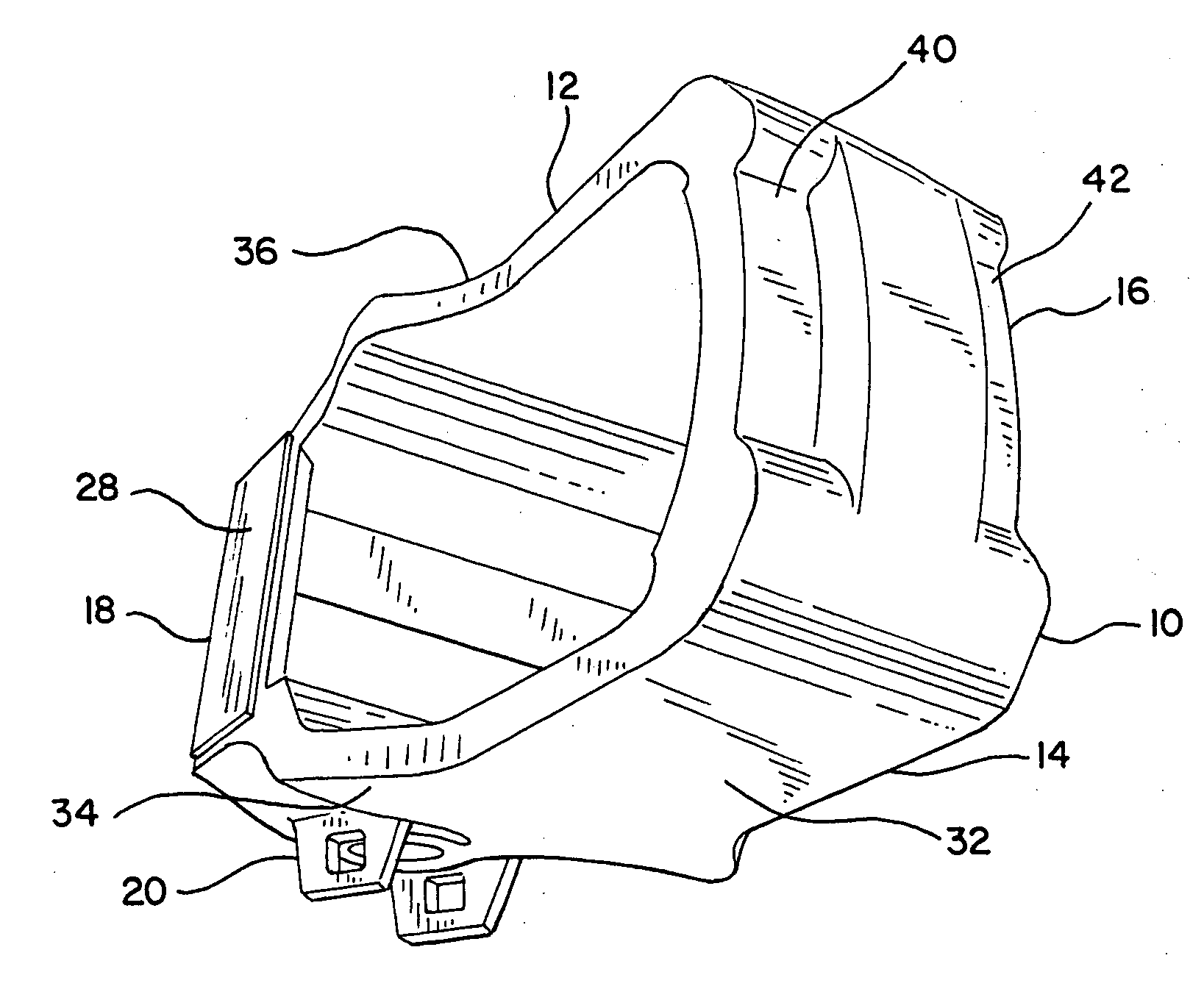

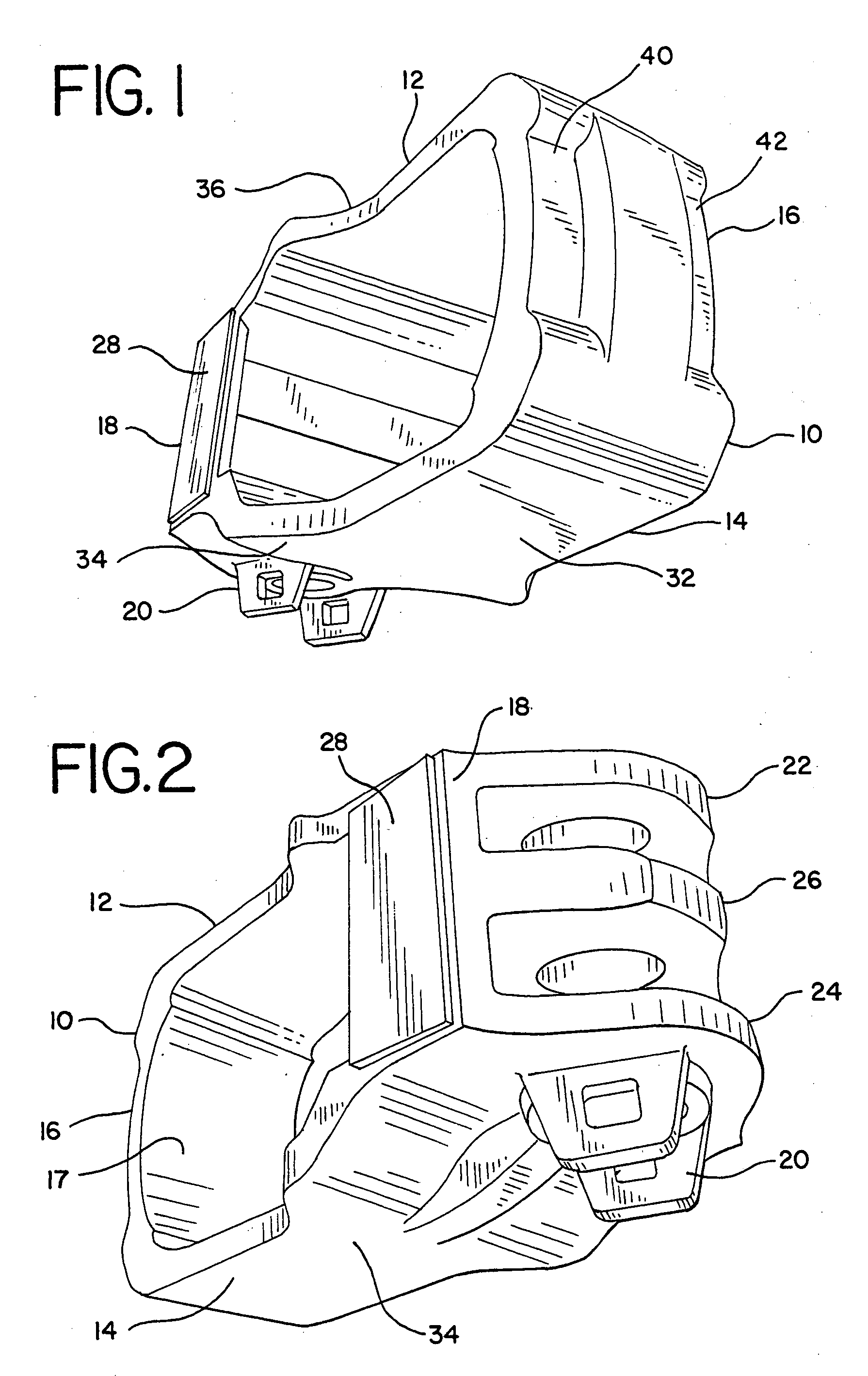

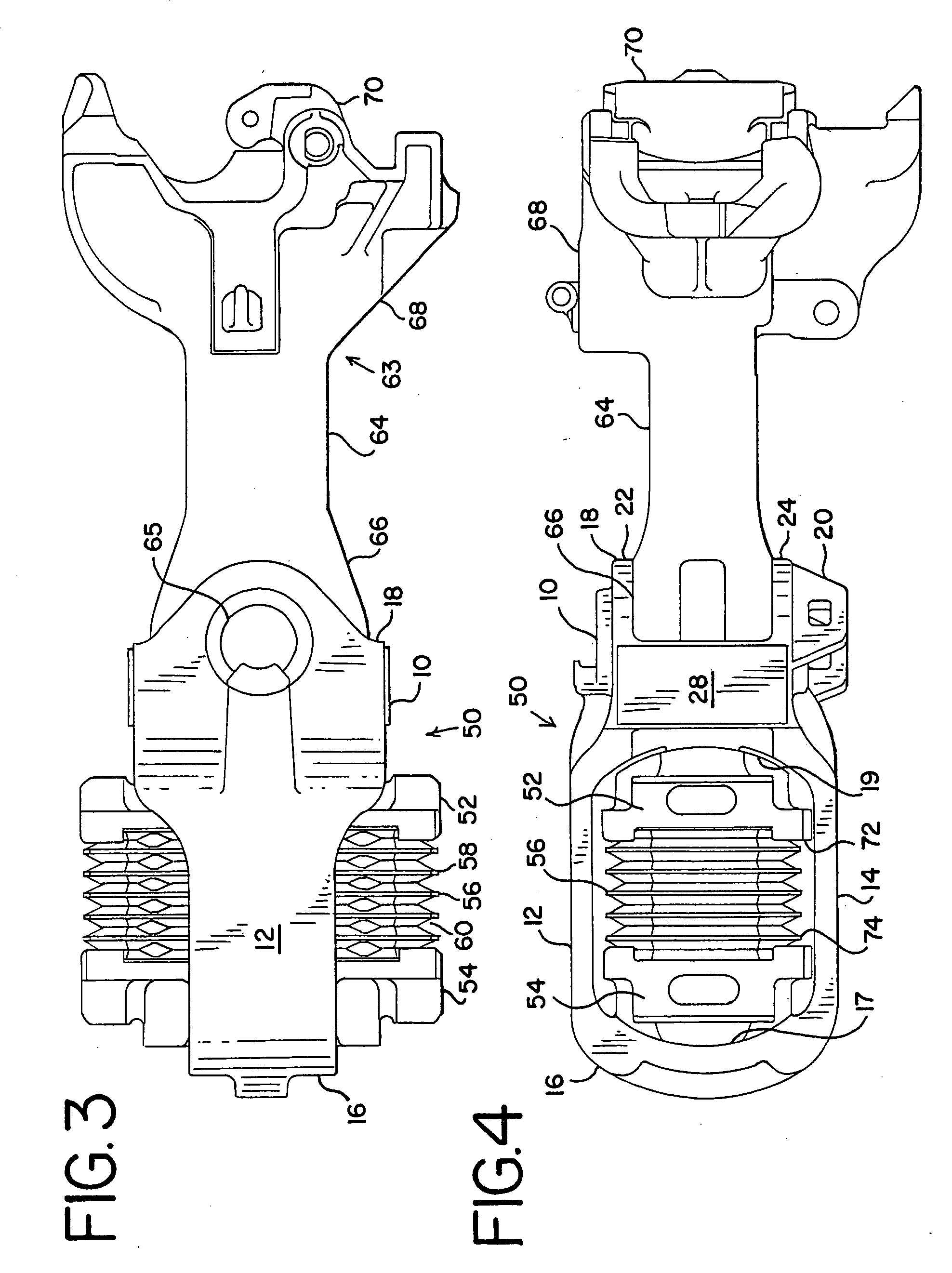

[0019] Referring now to FIGS. 1 and 2 of the drawings, a yoke for use in a locomotive draft gear assembly is shown generally at 10. Such yoke is typically a single casting of steel. Yoke 10 is seen to comprise an elongated top strap 12 and an elongated bottom strap 14. Rear end 16 of yoke 10 and front end 18 of yoke 10 are joined by top strap 12 and bottom strap 14.

[0020] Back wall 16 is shown as having an inner concave surface 17 adapted to abut against the complementary convex surface of the rear follower.

[0021] Front wall 18 is seen to comprise two side sections 28 that are spaced laterally and extend from top strap 12 to bottom strap 14. Front wall is further seen to comprise a top section 22, center section 26, and bottom section 24. Each of front wall top section 22, front wall center section 26 and front wall bottom section 24 are seen to have a convex edge extending from a center forward most portion back into contact with front wall side sections 28. A draft pin retainer ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com