Loading dock traffic automation and inventory control system

a technology for inventory control and loading docks, applied in the direction of individual entry/exit registers, lighting and heating apparatus, instruments, etc., can solve the problems of prone to failure of limit switches, high installation and maintenance costs, and high capital equipment costs of truck restraints, so as to achieve the effect of without the expense of a truck restrain

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

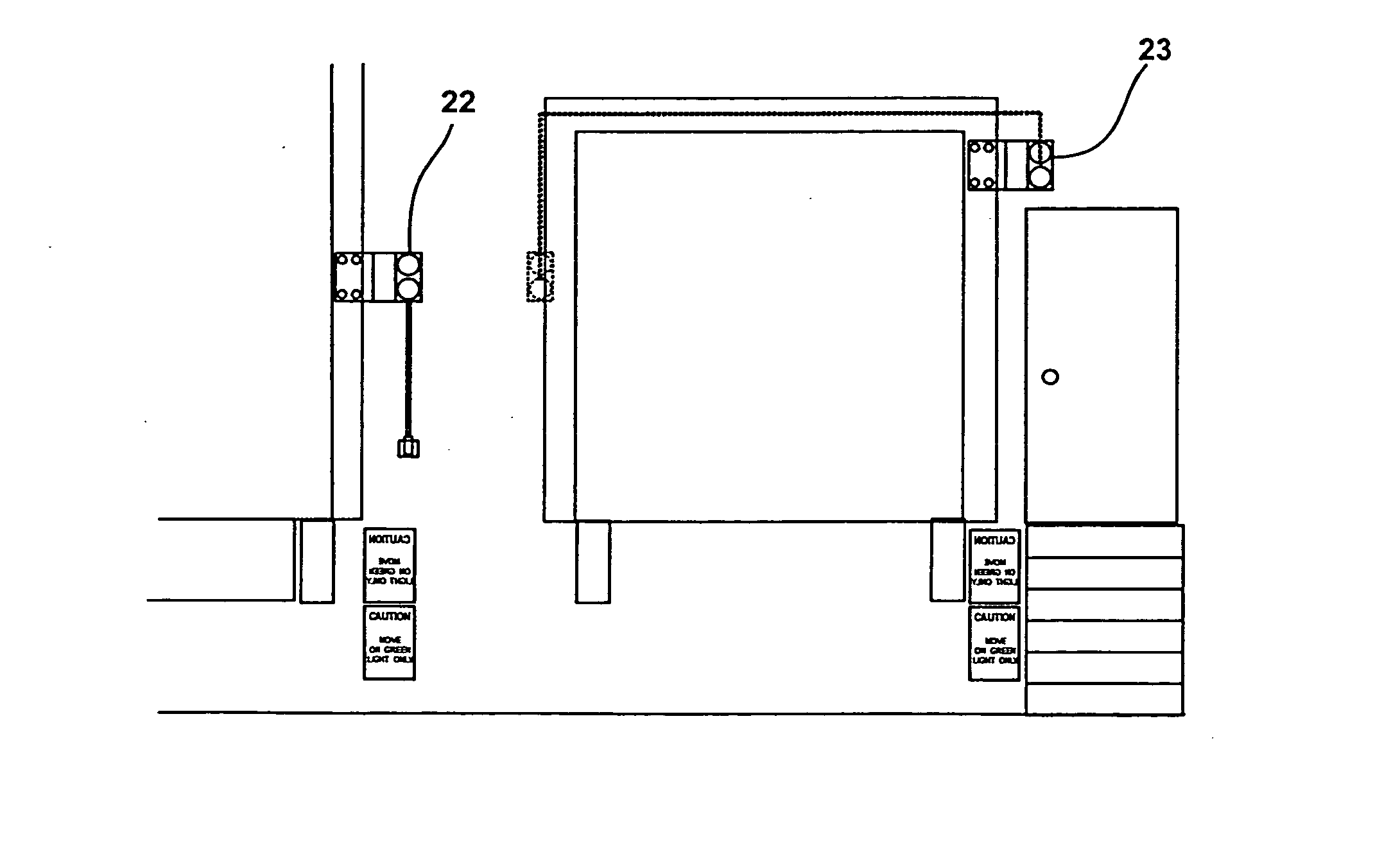

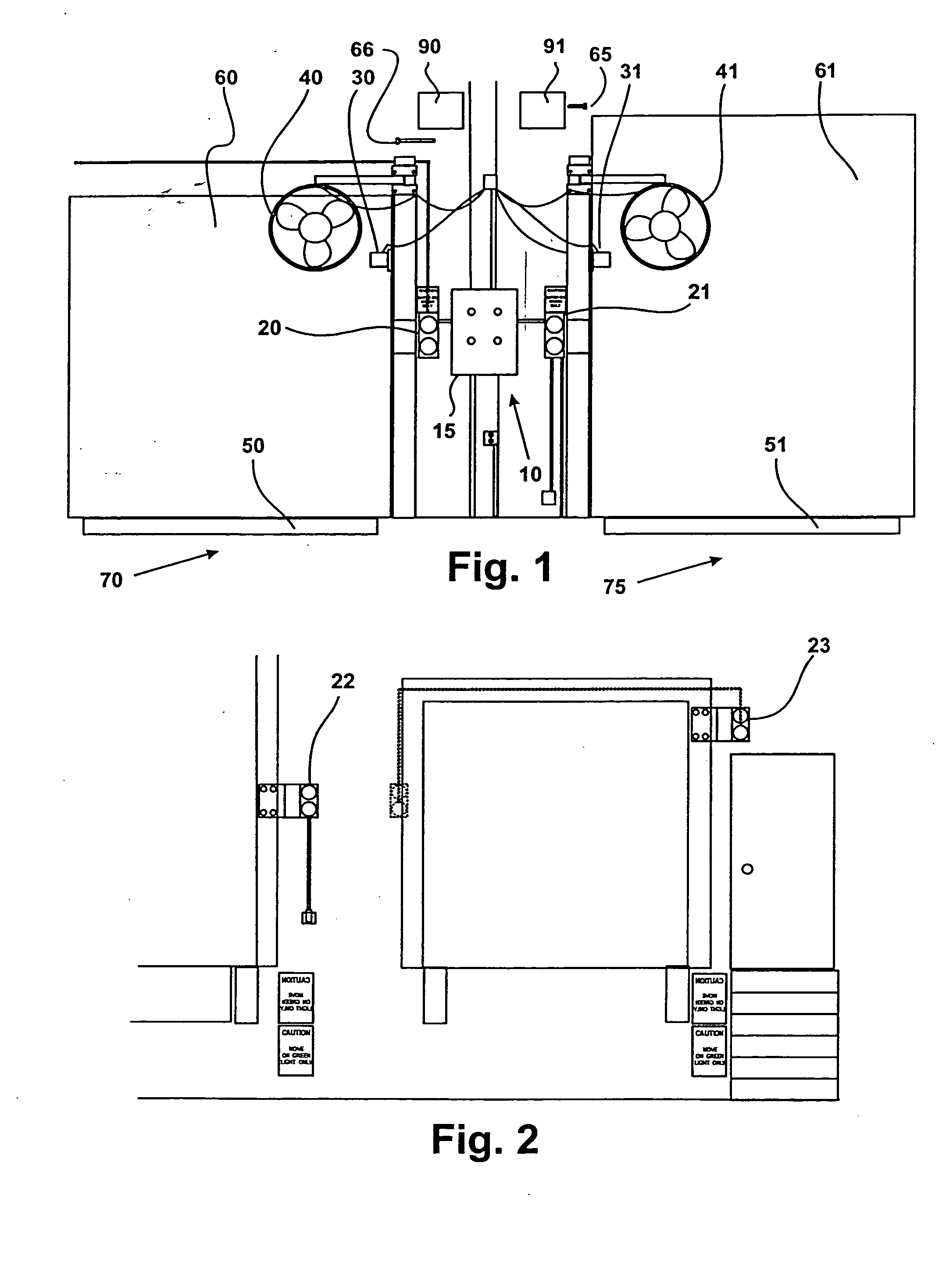

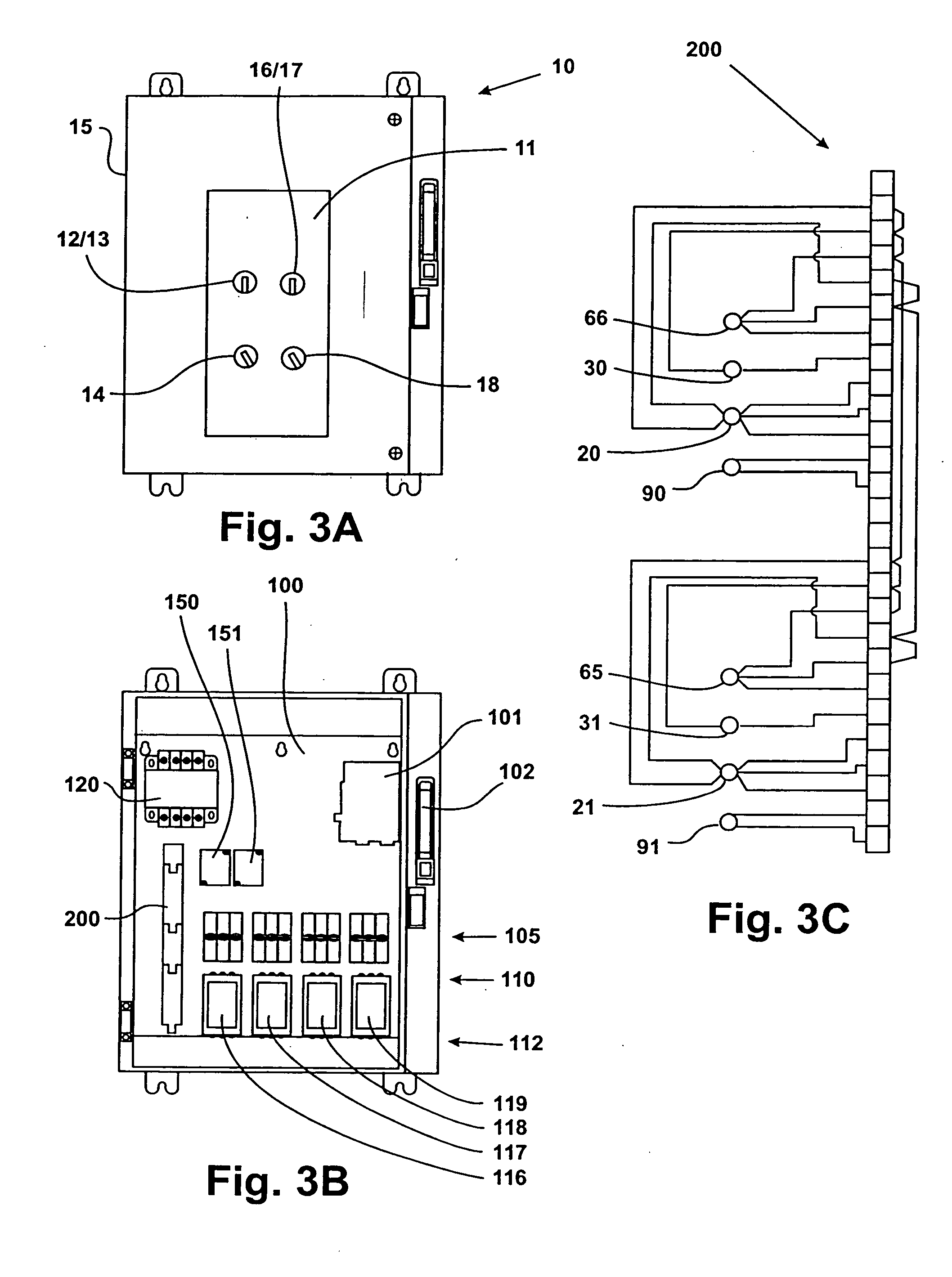

[0031]FIGS. 1 through 4 illustrate the 480 Volt, 3 Phase, 60 Hz embodiment of the device of the present invention.

[0032] The standard loading dock control panel for electrical dock levelers are usually one single control box system supplied with each individual specific piece of dock leveler equipment. Traditionally, control boxes are made to manually operate one specific piece of equipment. Loading dock fans and loading dock lights usually are supplied with a cord and plug for an electrical outlet.

[0033] An advantage of the present invention is to operate loading dock equipment, track shipments and track inventory simultaneously through an automation state with or without a manual process. As a safety feature and energy saver, the manual process must be energized to function by way of the automation process.

[0034] The automation dock door equipment process is controlled by a sensing means such as a limit switch, photo eye, motion detector, magnetic switch, or laser. These device...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com