Isolation packer inflated by a fluid filtered from a gravel laden slurry

a technology of filtered fluid and packer, which is applied in the direction of fluid removal, sealing/packing, and wellbore/well accessories, etc., can solve the problems of time-consuming, difficult to perform, and unreliable in their outcome, so as to save time and expense, the effect of difficult to perform

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

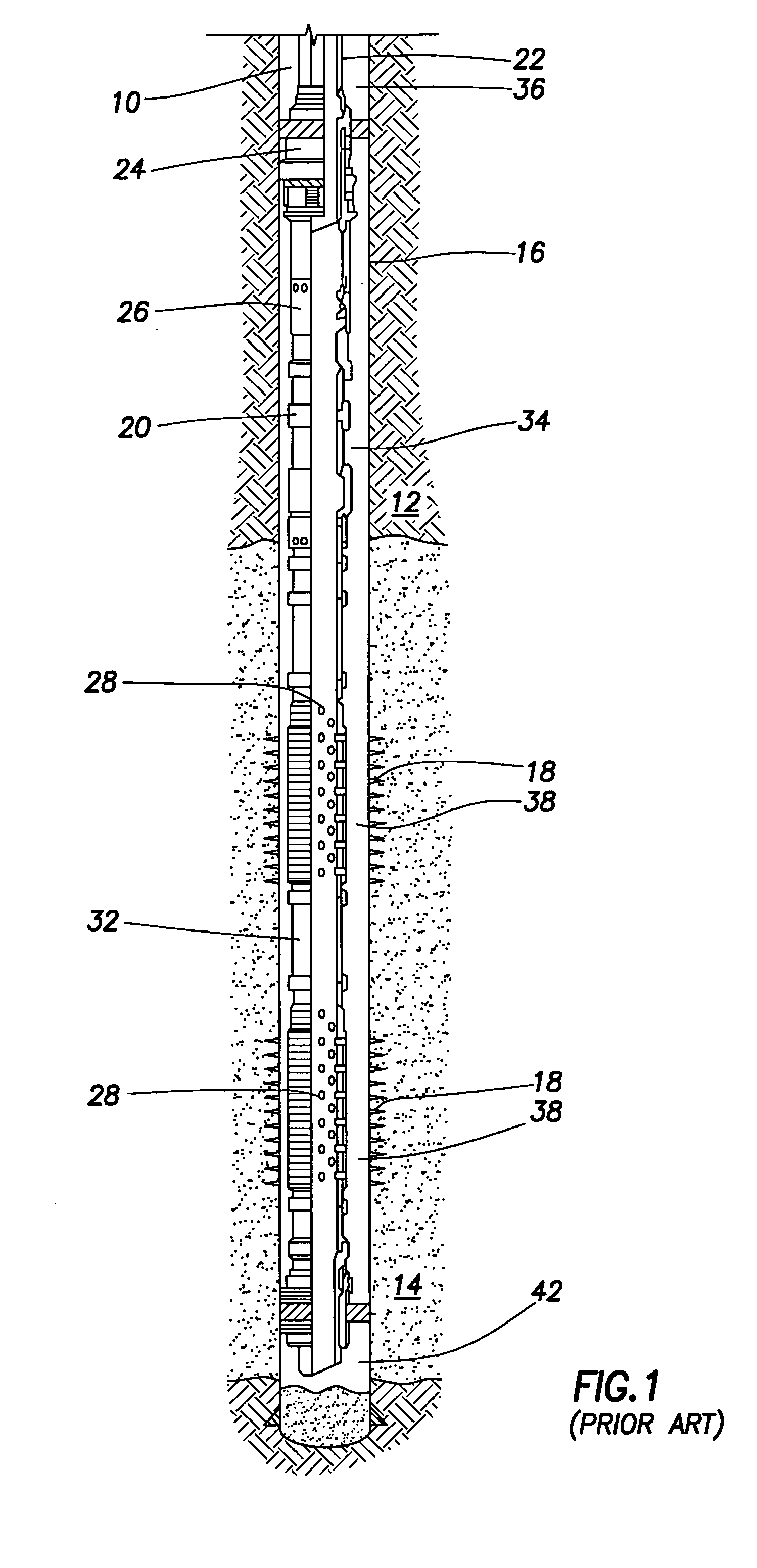

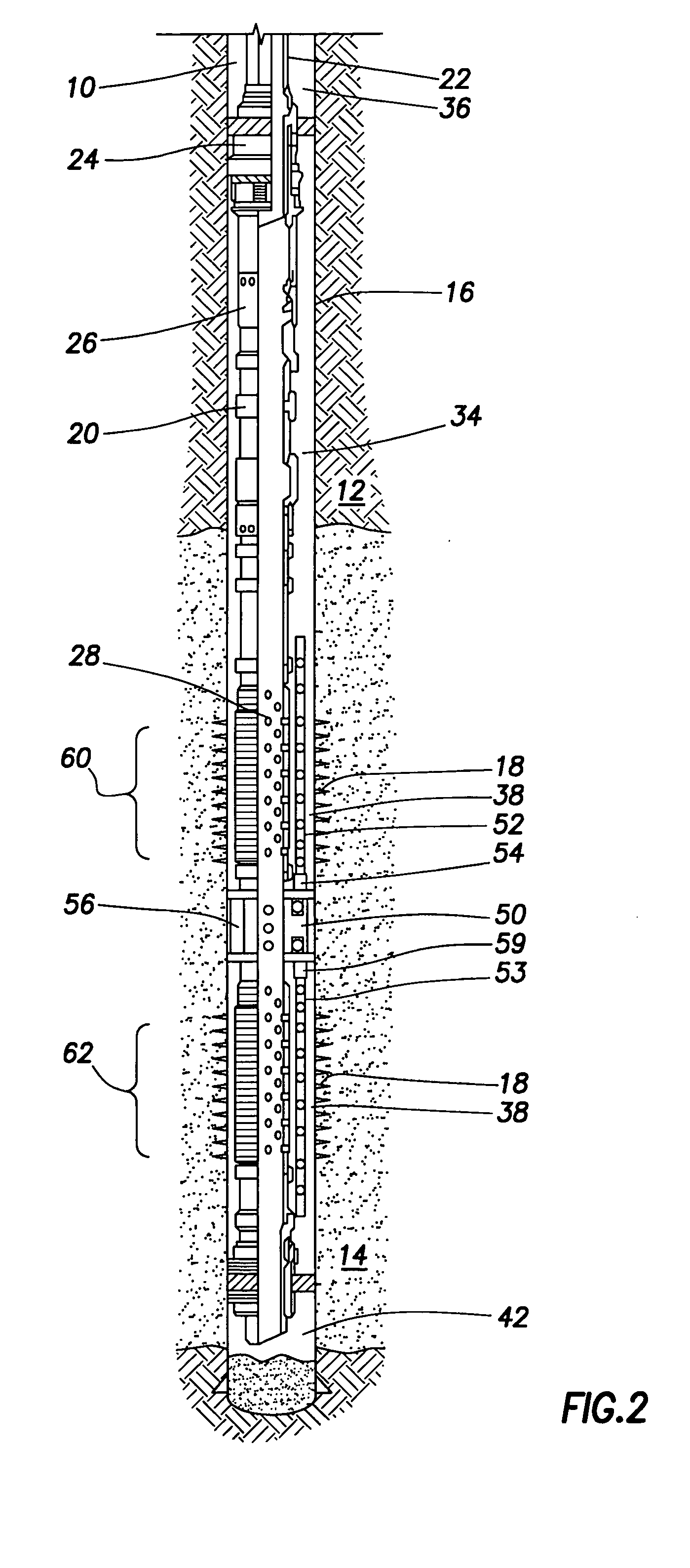

[0022] Referring to the attached drawings, FIG. 1 is a depiction of the prior art and illustrates a wellbore 10 that has penetrated a subterranean zone 12 that includes a productive formation 14. The wellbore 10 has a casing 16 that has been cemented in place. The casing 16 has a plurality of perforations 18 which allow fluid communication between the wellbore 10 and the productive formation 14. A well tool 20 is positioned within the casing 16 in a position adjacent to the productive formation 14, which is to be gravel packed.

[0023] The present invention can be utilized in both cased wells and open hole completions, as well as vertical wells and non-vertical wells. For ease of illustration of the relative positions of the producing zones in FIGS. 1-4, a cased well having perforations will be used. More detailed illustrations of the invention being utilized in an open hole completion are shown in FIGS. 8-9.

[0024] Still referring to FIG. 1, the well tool 20 comprises a tubular memb...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com