Battery terminal and method for making the same

a battery terminal and battery case technology, applied in the field of battery terminals, can solve the problems of acid solution leaking out of the battery case, unsatisfactory resistance to rotation, etc., and achieve the effects of minimizing or preventing fluid leakage, reducing corrosion, and improving torque-turning resistan

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

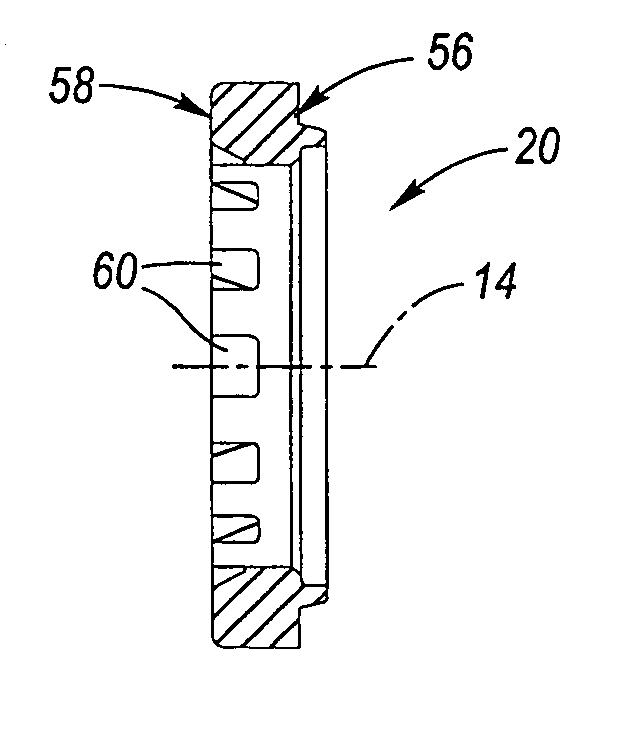

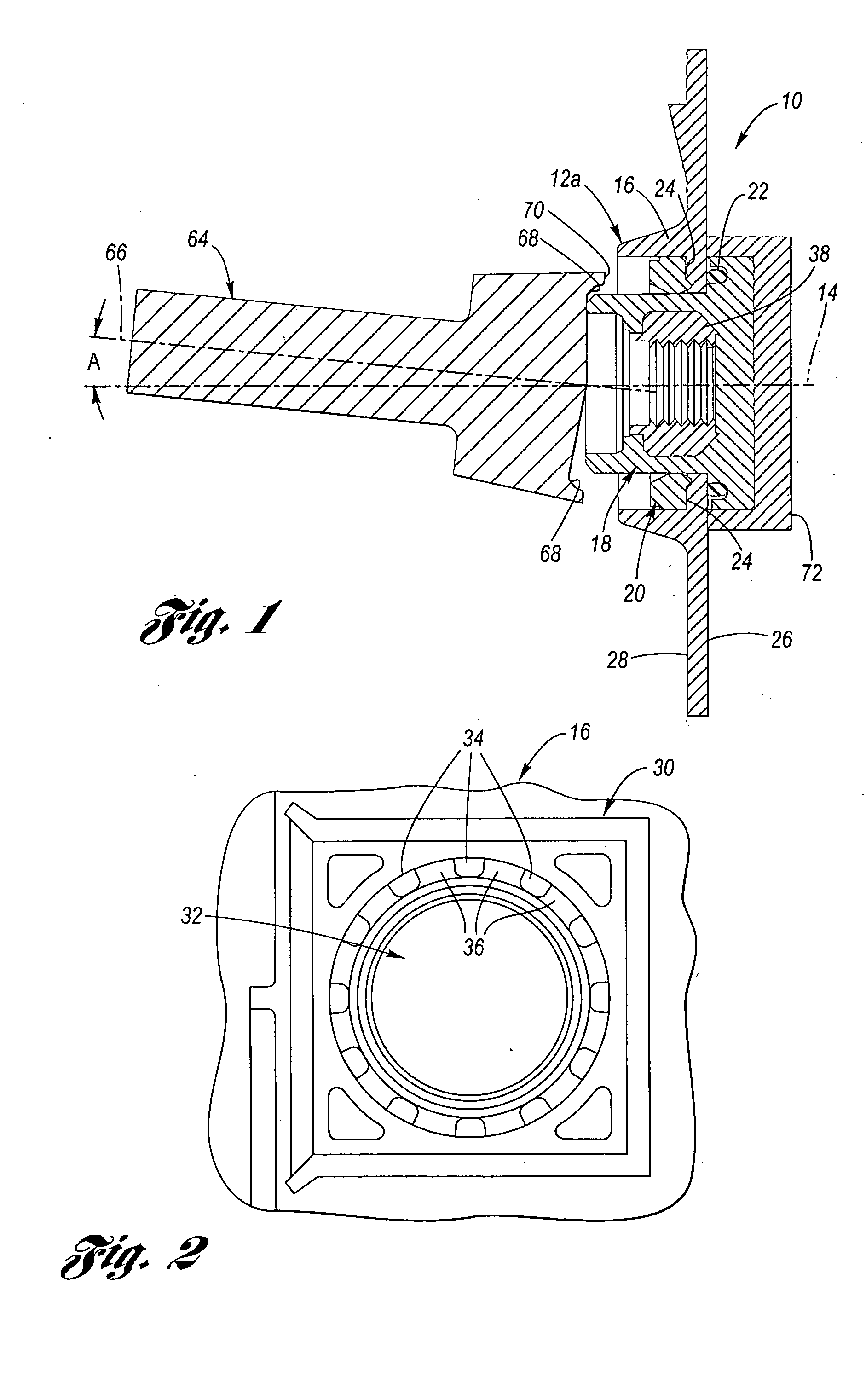

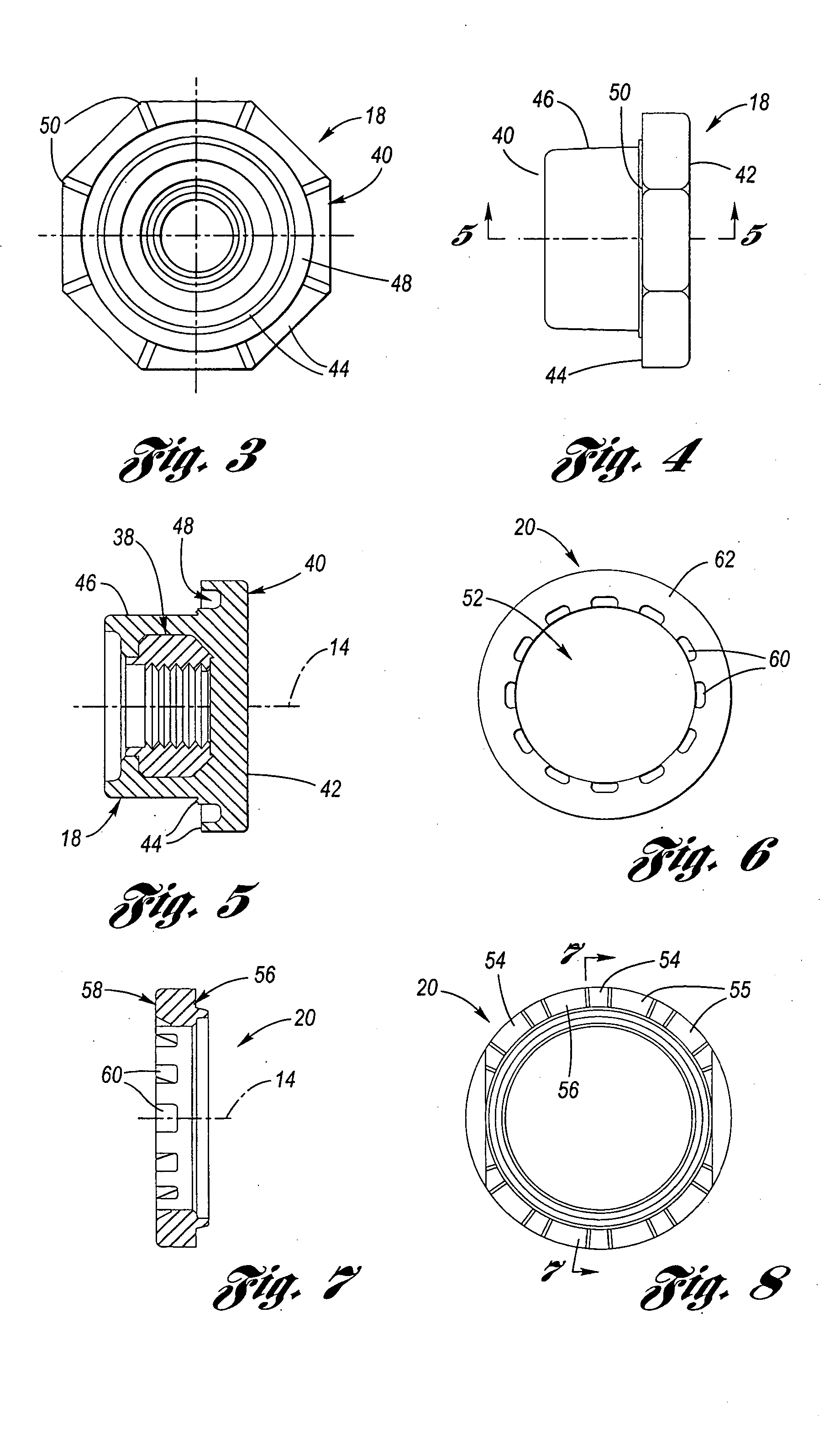

case 16

[0020] Case 16 is configured generally to retain the inner components of battery 10, and may comprise conventional, electrical insulating material, such as various plastics (e.g., polypropylene). As shown in FIG. 1, battery case 16 includes an inner or inside surface 26, and an outer or outside surface 28. For reference, inner surface 26 faces the interior of storage battery 10, and is configured to, during the service life of storage battery 10, come into contact with sulfuric acid solution, for example.

[0021] Referring to FIG. 2, battery case 16 further includes a pair of main bosses 30 (only one shown in FIG. 2) that are configured, generally, to cooperate with the components described herein to form the battery terminal 12. Main boss 30 includes a central through-bore 32, and a set of angularly-spaced lands or bosses around bore 32, separated by and raised relative to, intervening slots 36. As will be described in greater detail below, bosses 34 and slots 36 form part of a termi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com