Container cap assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

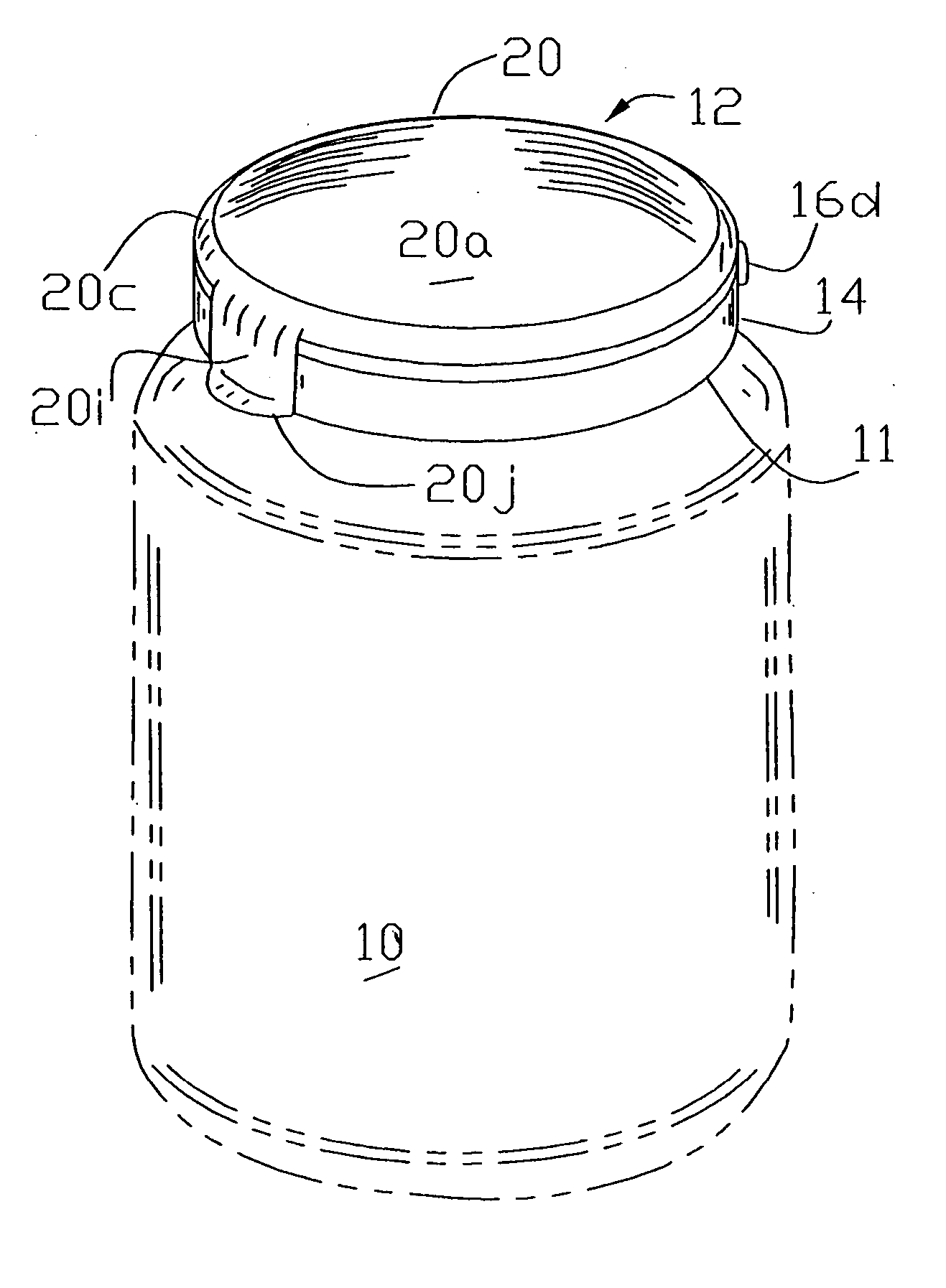

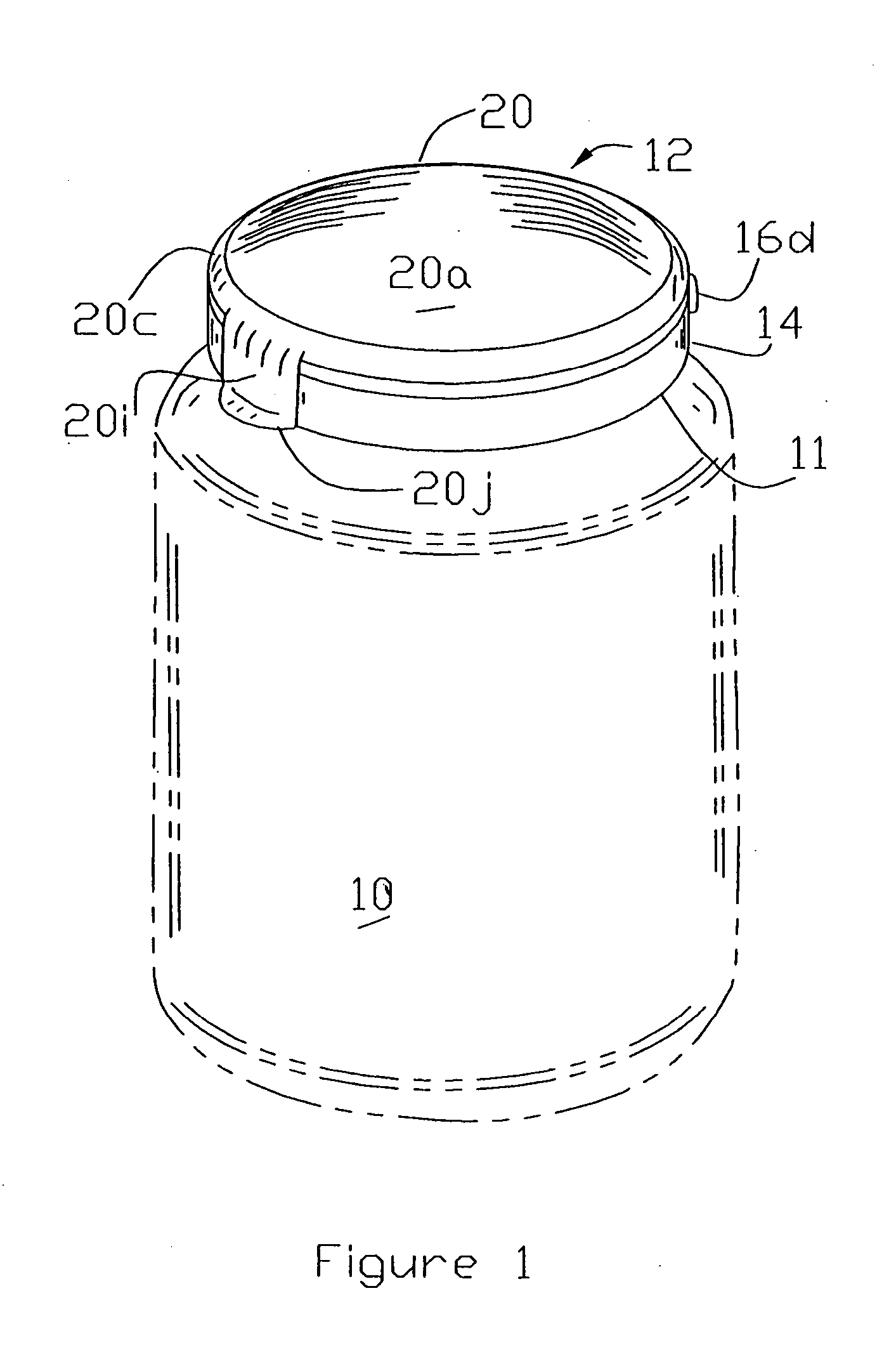

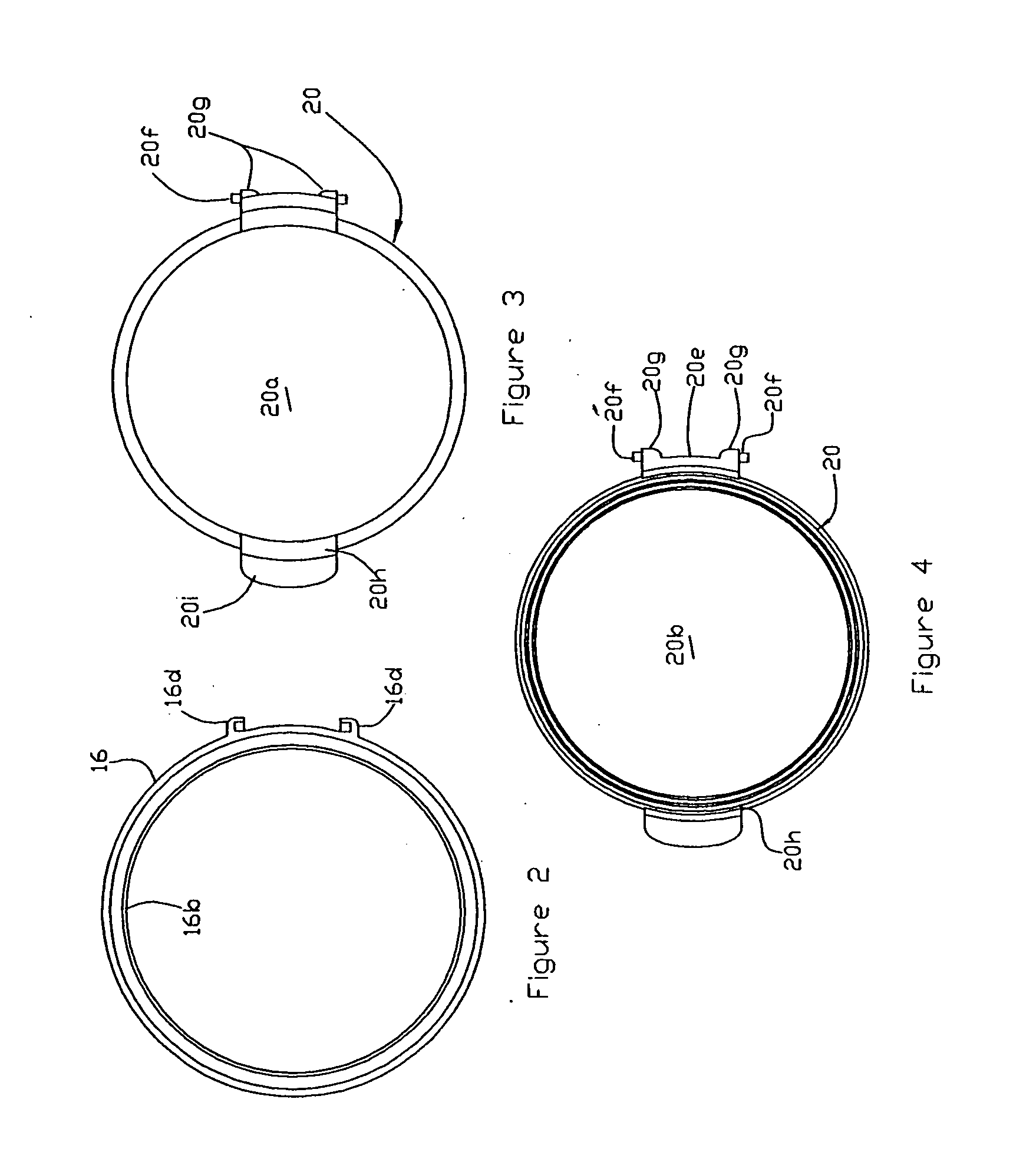

[0033] Referring more particularly to FIG. 1, there is shown a pictorial view of a container 10 having a neck portion 11 on which is commonly formed an external thread (not shown). It should be readily understood that container 10 is illustrative of various types and sizes of containers, such as bottles, jars, and the like, that hold liquids as well as dry food products.

[0034] A container cap assembly, generally designated at 12, is shown mounted on the container 10 and is formed from a suitable rigid or semirigid thermoplastic material of, for example, the polyolifin group, such as high density polyethylene, more preferably from a polypropylene that provides some flexibility and memory. Polypropylene is believed to be the least expensive of most commonly used plastics for molding many consumer products and thus advantageous from the cost standpoint. The container 10 is illustrated as a large mouth container, for example, having a standard diameter of 53 mm, 63 mm, 89 mm, 110 mm or...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com