Snap knife with improved safety and usability

a technology of safety and usability, applied in the field of utility knives, can solve the problems of affecting the use of users, affecting the safety of users, and affecting the use of the user, so as to achieve the effect of increasing safety and usability and quickly snapping off the blad

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

embodiment

PREFERRED EMBODIMENT

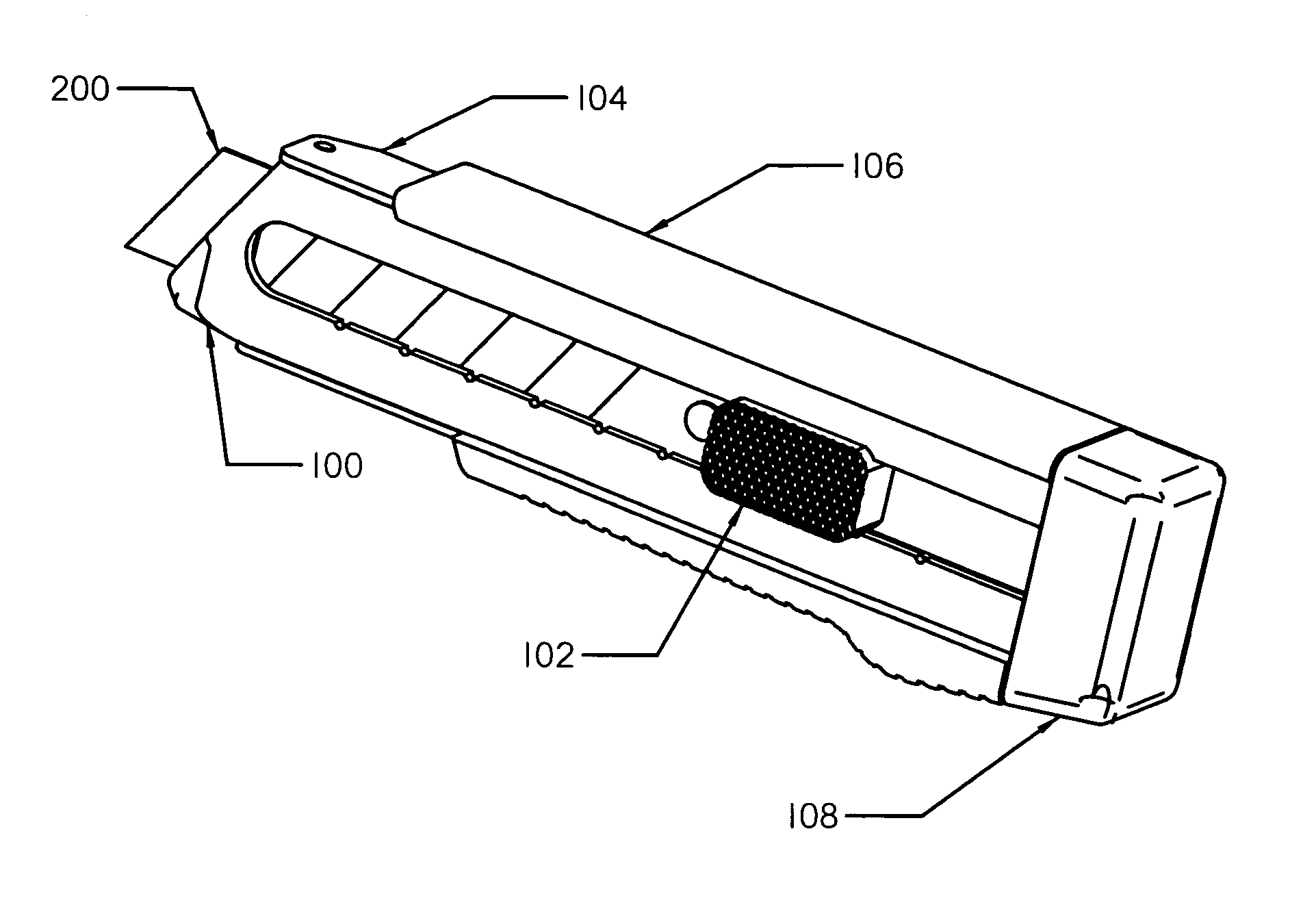

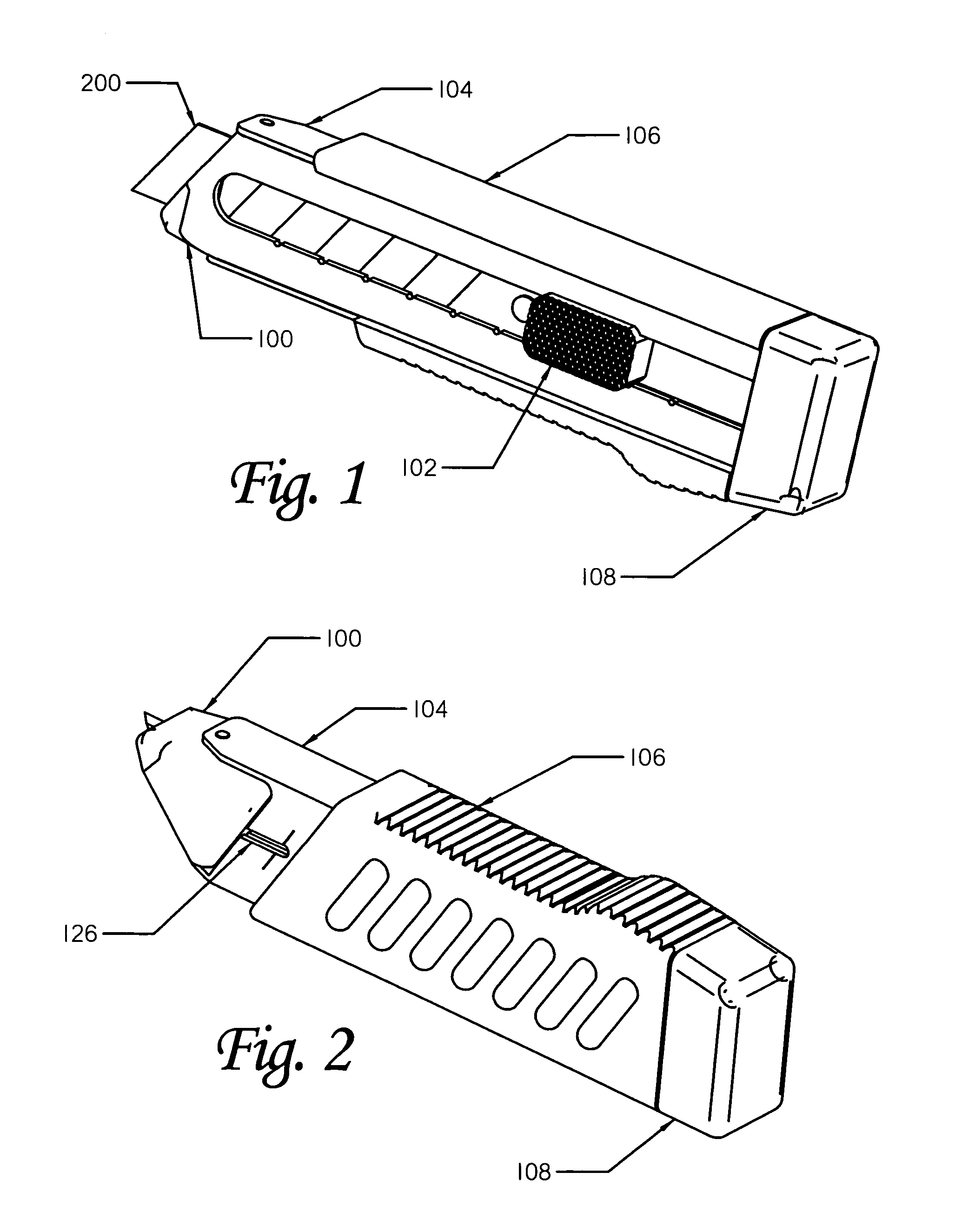

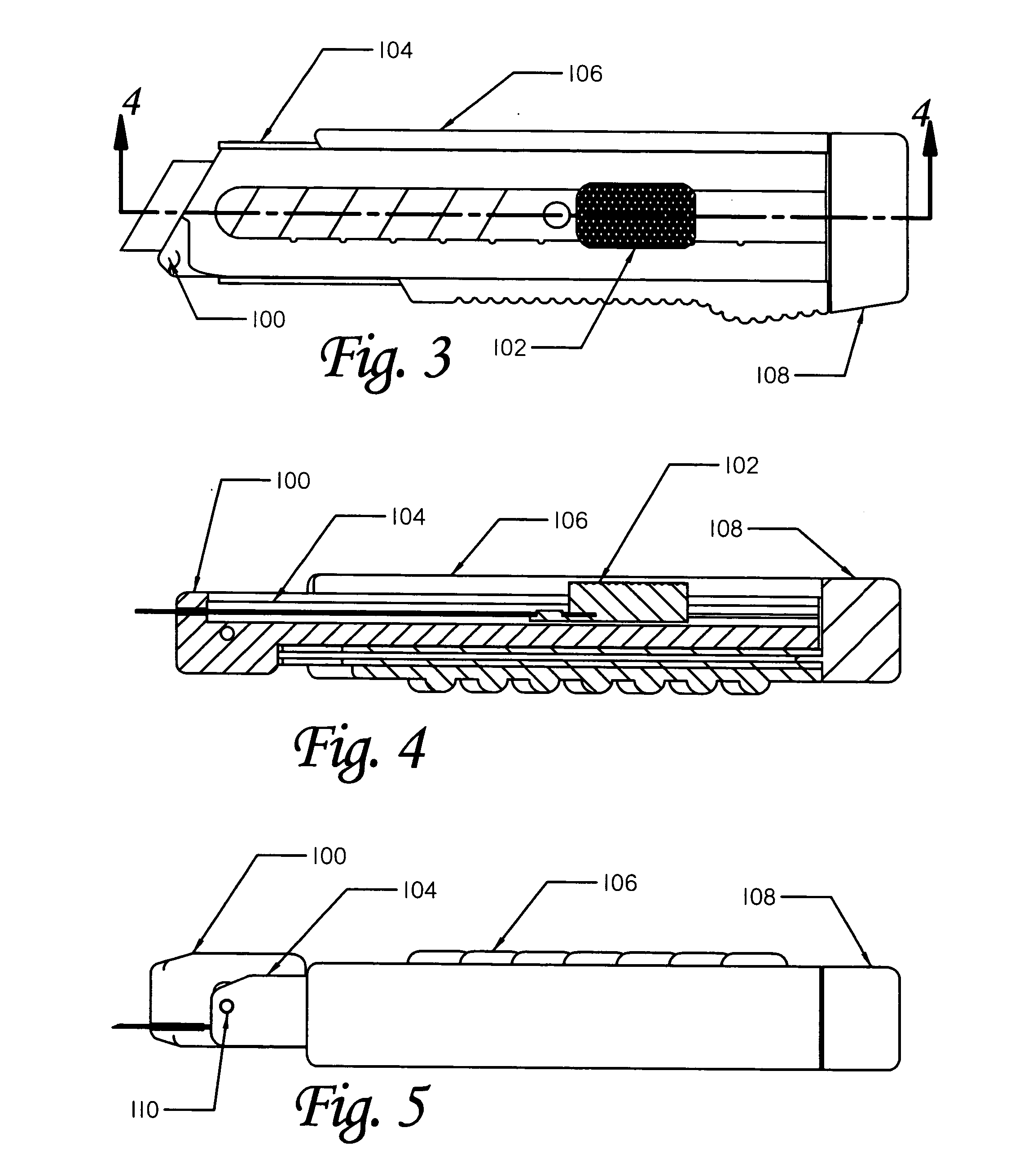

[0051] The disclosed invention is described below with reference to the accompanying figures in which like reference numbers designate like parts. Generally, numbers in the 200's refer to prior art elements or elements in the surrounding environment while numbers in the 100's refer to elements of the invention. Note that the blade illustrated in the figures, and described below, is not a part of the invention itself.

[0052] Overview

[0053] The present invention is a snap-knife with significantly improved usability and safety. These both result primarily by the provision of a means of snapping off blade segments which eliminates all need for the user to touch the blade during or after the operation. The handle is simply opened outward to the fully extended position, the blade extended to enter the breaking slot in the opposite part of the handle, and the handles closed again, The pivoting motion of the handles as they close snaps off the blade and the removed segm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com