Operator's seat supporting device for service vehicle

a technology for operating seats and vehicles, which is applied in the direction of vehicle components, vehicle arrangements, chairs, etc., can solve the problems of inability to effectively utilize space, disadvantageous low rigidity in the lateral direction, and difficulty in ensuring strength against load, etc., to achieve convenient cleaning, wide space, and comfortable posture

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

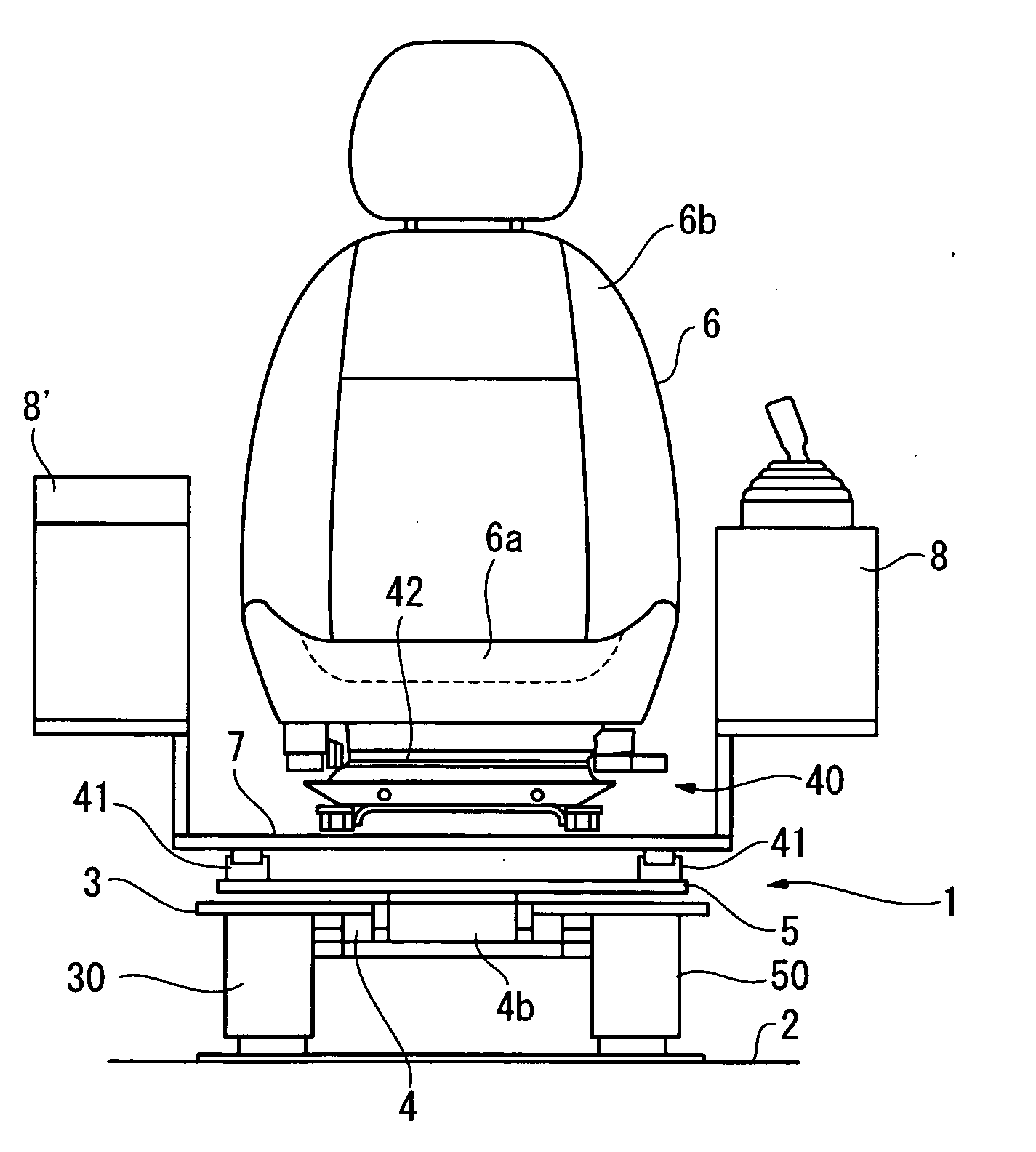

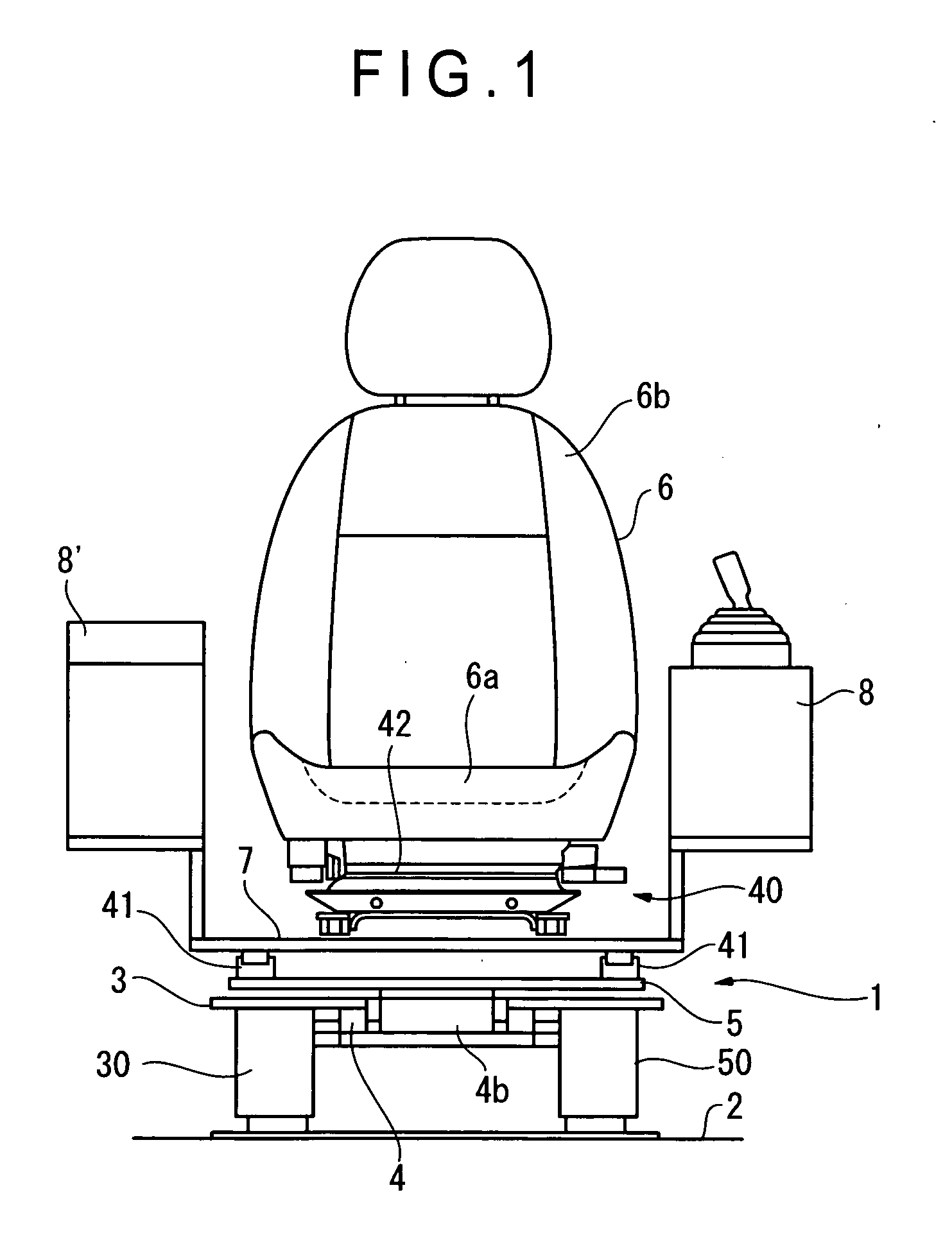

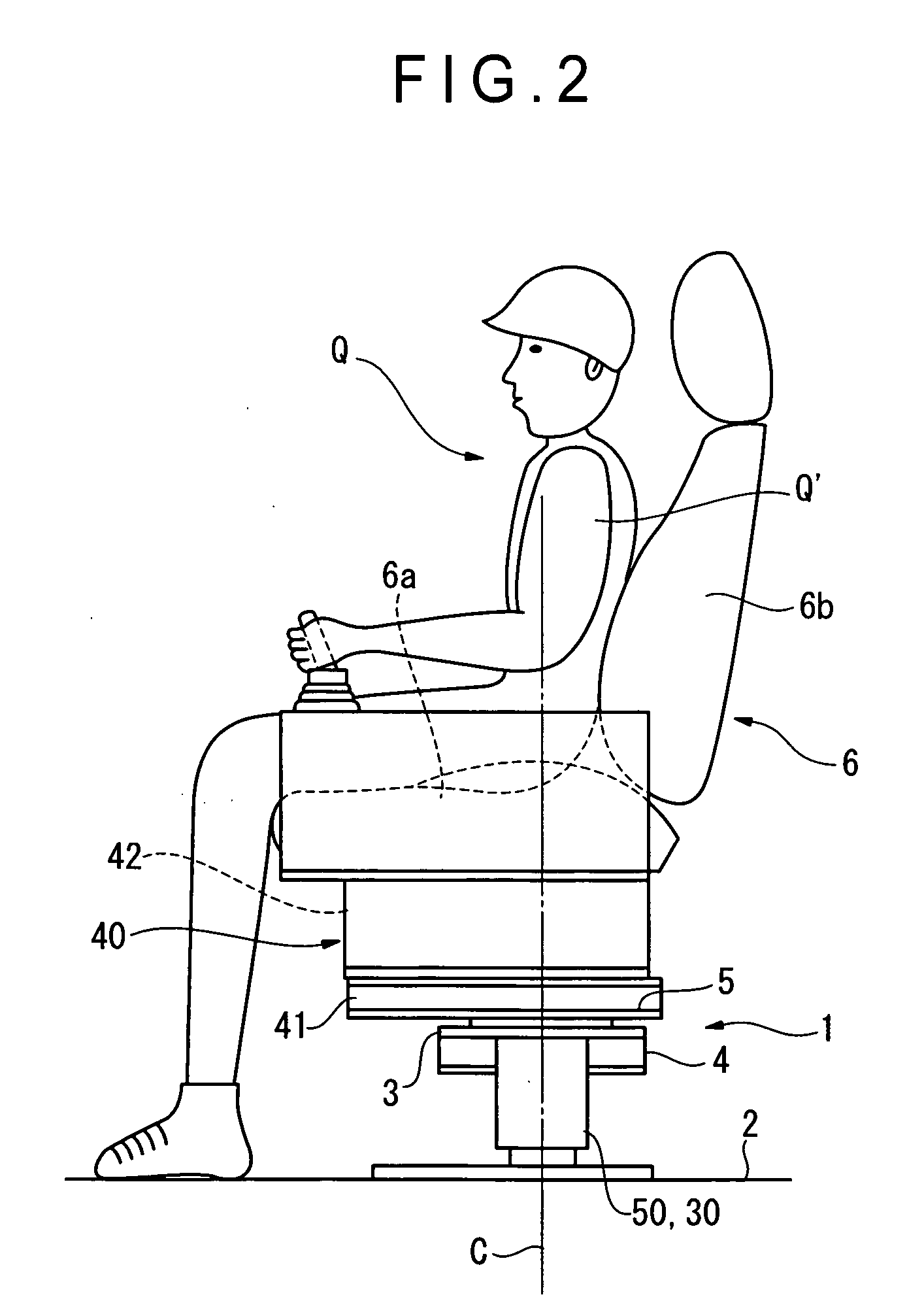

[0039]FIG. 1 is a front elevational view showing a first embodiment of the operator's seat supporting device for a service vehicle according to the present invention; FIG. 2 is a side elevational view of FIG. 1; FIG. 3 is a longitudinal cross-sectional view showing a damping function control mount; FIG. 4 is a cross-sectional view showing the primary portion of the damping function control mount cylinder; and FIG. 5 is a longitudinal cross-sectional view showing a supporting damper.

[0040] An operator's seat supporting device 1 according to this embodiment includes two damper cylinders 50, 30 erecting from and provided on a floor surface 2 of an operator's cabin with a prespecified space; a posture adjusting section 40 provided on a movable supporting plate 5 disposed via a rotating mechanism 4 on a supporting plate 3 supported by these damper cylinders 50, 30; and an operator's seat 6 mounted via this posture adjusting section 40.

[0041] Of the damper cylinders 50, 30, one is a dam...

second embodiment

[0086] Next, referring to FIG. 6, a second embodiment of the present invention is described below.

[0087] In the present embodiment, it is only different from the operator's seat supporting device I according to the first embodiment that the structure of the damper cylinder 50 (damping function control mount cylinder) is modified. In the following, the description of the components have been described already or that of the same components as the above-described components will be omitted or simplified.

[0088] The damper cylinder 10 according to the second embodiment having a magnetic Theological fluid control function includes, as shown in the cross-sectional view in FIG. 6, a buffering cylinder 13 externally and coaxially engaging a fixed member 11 having a mounting base 12 against the floor surface 2 (corresponding to the biaxial slide support structure according to the present invention), a coil spring 19 for restoring a damper provided inside the fixed member 11, and a control ...

third embodiment

[0098] Next, FIG. 8 is a cross-sectional view showing a third embodiment of a damping function control mount cylinder.

[0099] Basic configuration of the damping function control mount cylinder (described simply as a damper cylinder 10A hereinafter) is the same as that in the embodiment described above, but the combinatorial structure is different from that in the embodiment described above. Therefore the basic actions and effects are the same as those described in the respective embodiments described above. It is to be noted that the same reference numerals are assigned to the same components as those in the embodiment described above and detailed description is omitted herefrom. Therefore description is made only to components having different functions respectively.

[0100] The damper cylinder 10A according to this embodiment has a control cylinder 20A incorporated in and at a central position of the buffering cylinder 13A.

[0101] Further a coil spring 19A for restoration is provid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com