Branch wire tie band, binding structure, and method of binding a wiring harness

a branch wire and tie-band technology, applied in the direction of hose connections, flexible elements, packaging, etc., can solve the problems of reducing the positioning precision of the branched portion, excessive time required to perform the tape wrapping operation, and the quality of the tape wrap may vary, so as to achieve convenient tightening and simple and economical

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

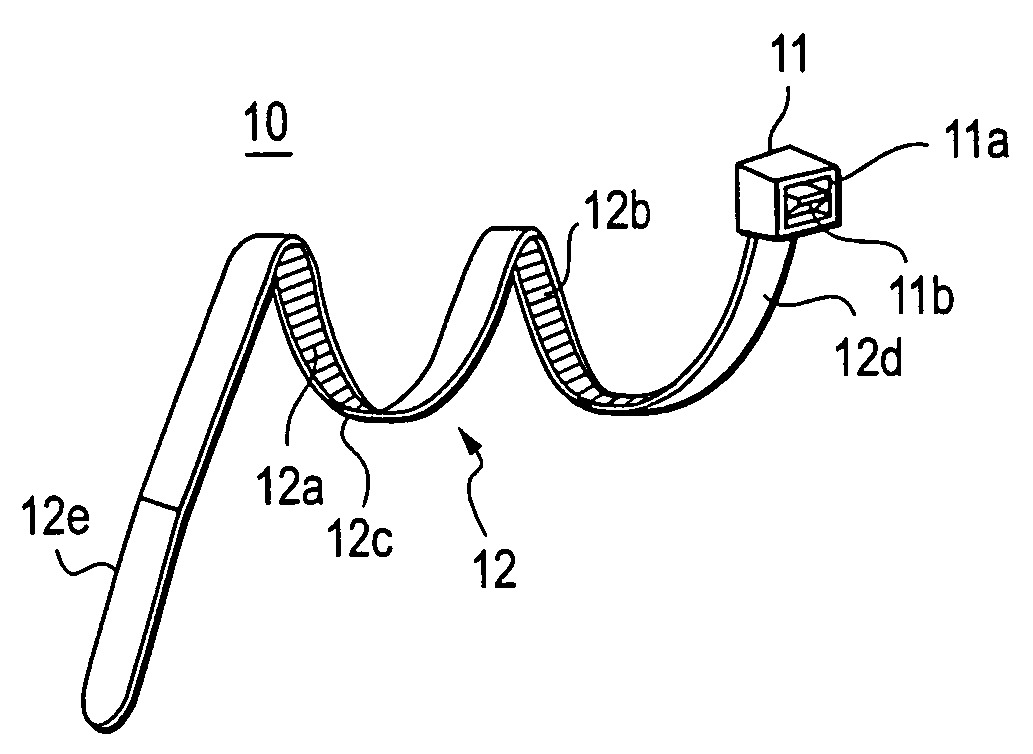

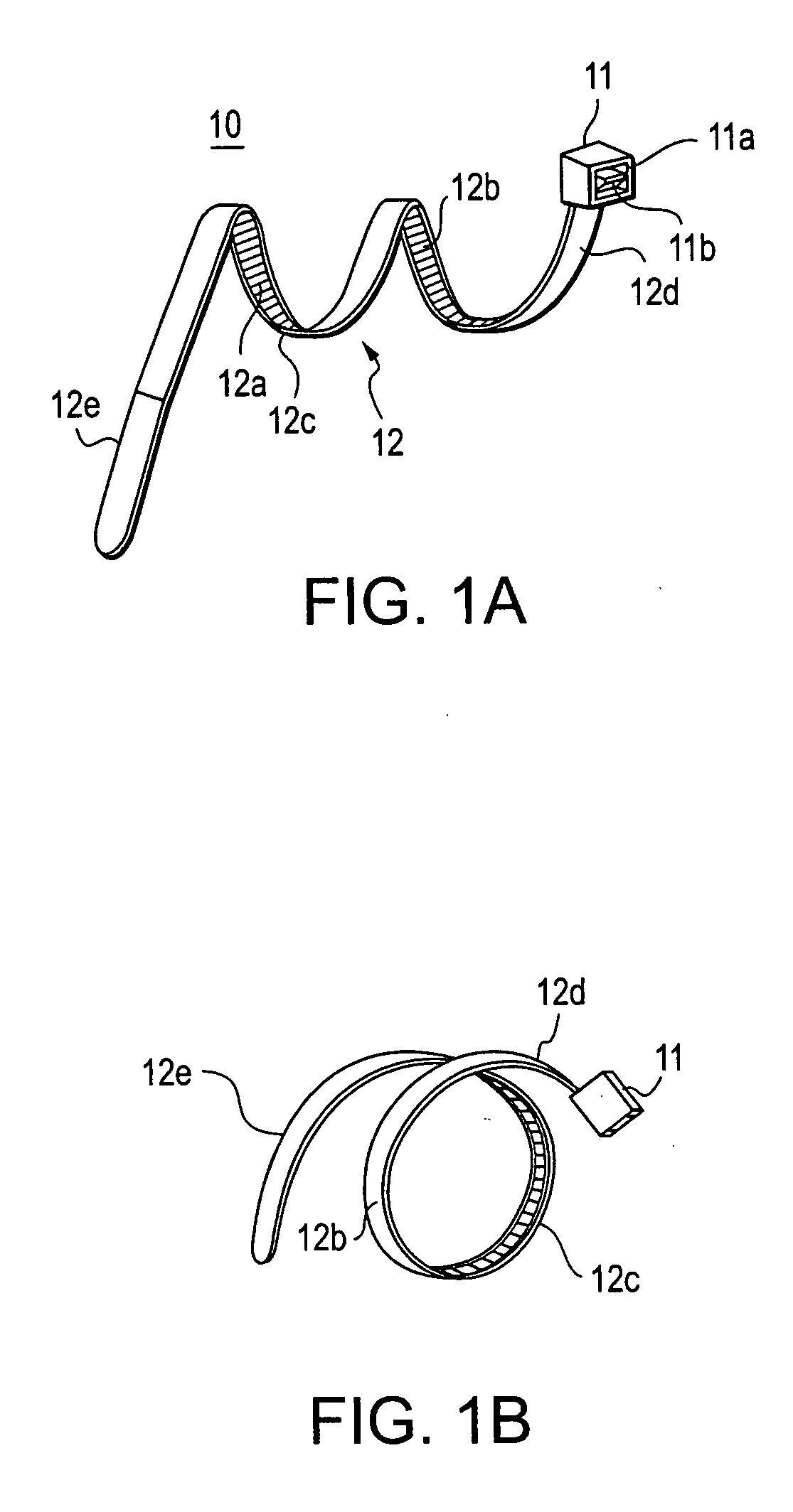

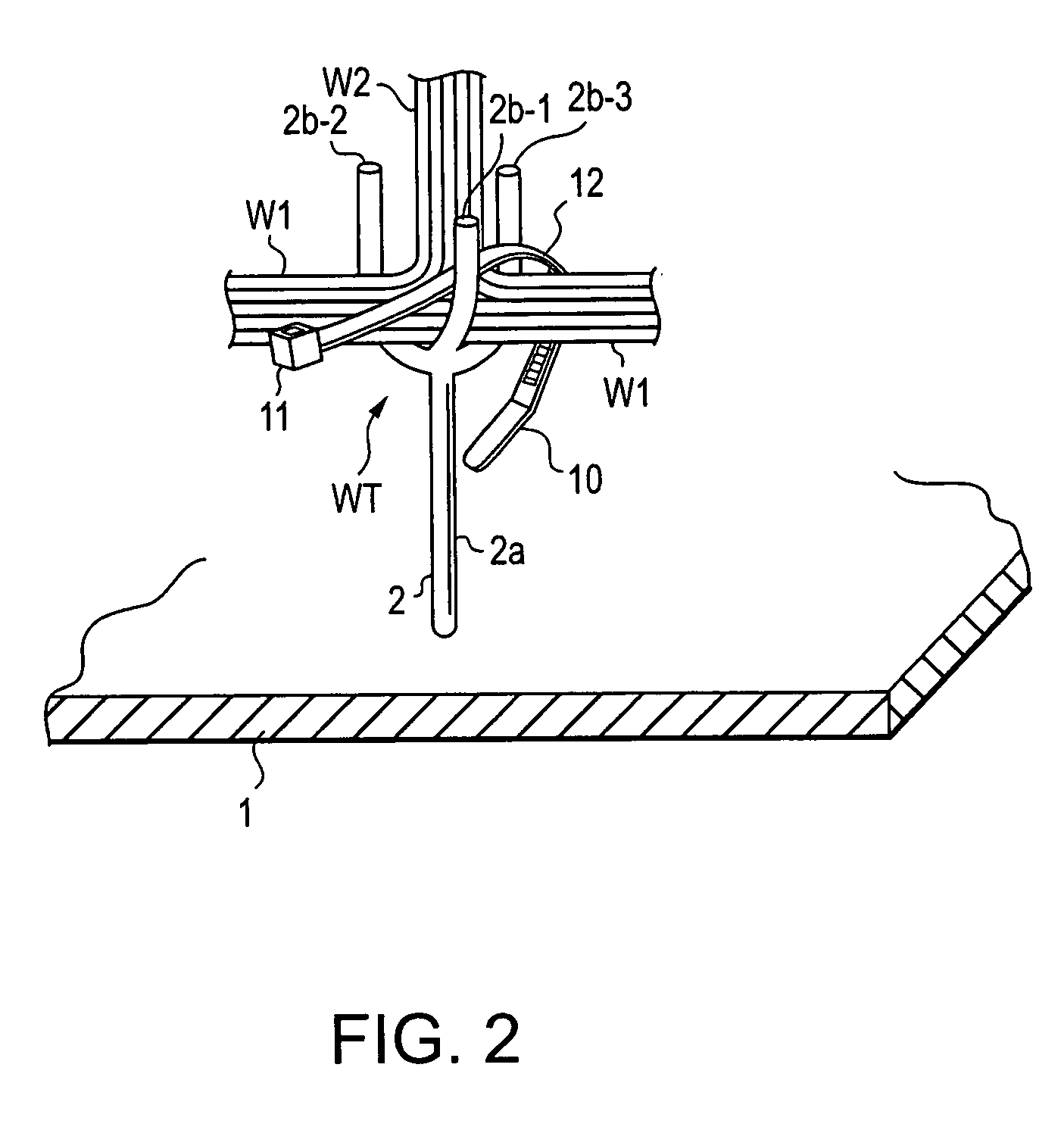

[0059] The following will explain embodiments of the invention with reference to the drawings. FIGS. 1 through 3 illustrate the invention. FIG. 1 illustrates branch wire tie band 10 (hereafter referred to as tie band 10) which may be made of any suitable material such as, for example, a synthetic resin, and in the present embodiment the resin is polypropylene. Tie band 10 includes box-shaped head portion 11 from which extends strap 12. Lock pawl 11b protrudes into lock channel 11a which is formed within head portion 11. Strap 12, onto which ratchet teeth 12a are formed, is inserted into lock channel 11a and secured at a position therein through the engagement of any of ratchet teeth 12a against lock pawl 11b.

[0060] Strap 12 is a narrow belt-shaped strap that has been formed into a spiral shape extending from head portion 11 to the tip of the strap. Half-loop shaped first and second attachment coils 12b and 12c connect to form one complete loop from which head portion side 12d conti...

third embodiment

[0072] the present invention is shown in FIGS. 12 through 14. As illustrated in FIG. 12, branch wire tie band 110 (hereafter referred to as tie band 110) includes two bands in the form of first tie band 111 and second tie band 112, and anchor plate 13. Tie bands 111 and 112 are utilitarian tie bands of identical configuration.

[0073] Anchor plate 13 is a narrow, flat, planar member of any suitable material such as, for example, resin, into which two through holes 13a and 13b are formed at the right and left ends. Tie bands 111 and 112 include straps 111a and 112a that are loosely inserted into through holes 13a and 13b which are formed to a dimension large enough to allow the inclination of straps 111a and 112a therein, but small enough to prevent head portions 111c and 112c, which are part of tie bands 111 and 112 and contain lock channels 111b and 112b formed therein, from passing there through.

[0074] Lock pawls 111e and 112e project within lock channels 111b and 112b of first and...

fourth embodiment

[0084] The procedure through which tie band 110″ is attached and wrapped around T-shaped wire branch WT has been omitted as it is identical to the attachment procedure described in the

[0085] As noted previously, the present invention includes a wire branch tie band structure that includes an anchor plate in which a pair of through holes are formed, and a pair of utilitarian tie bands whose strap portions are inserted through the anchor plate through holes which are formed large enough to allow sufficient inclination of the straps therein. This structure offers a simple branch wire binding operation in which the tie bands are able to bind a branching wire location by wrapping around and mutually crossing over the trunk wires at each side of the branch wires, after which each strap is inserted and locked within the lock channel of the other tie band.

[0086] Moreover, as noted above, the procedure through which each strap is wrapped around the trunk wires at both sides of the branch wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com