Easy-to-unseal packaging bag

a packaging bag and easy-to-unseal technology, which is applied in the directions of flexible container closure, semiconductor/solid-state device details, containers, etc., can solve the problems of reducing the strength of the portion to which the scar is provided, content is broken or deformed upon opening the bag, and the strength of the sealed portion is reduced. , to achieve the effect of opening simpl

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

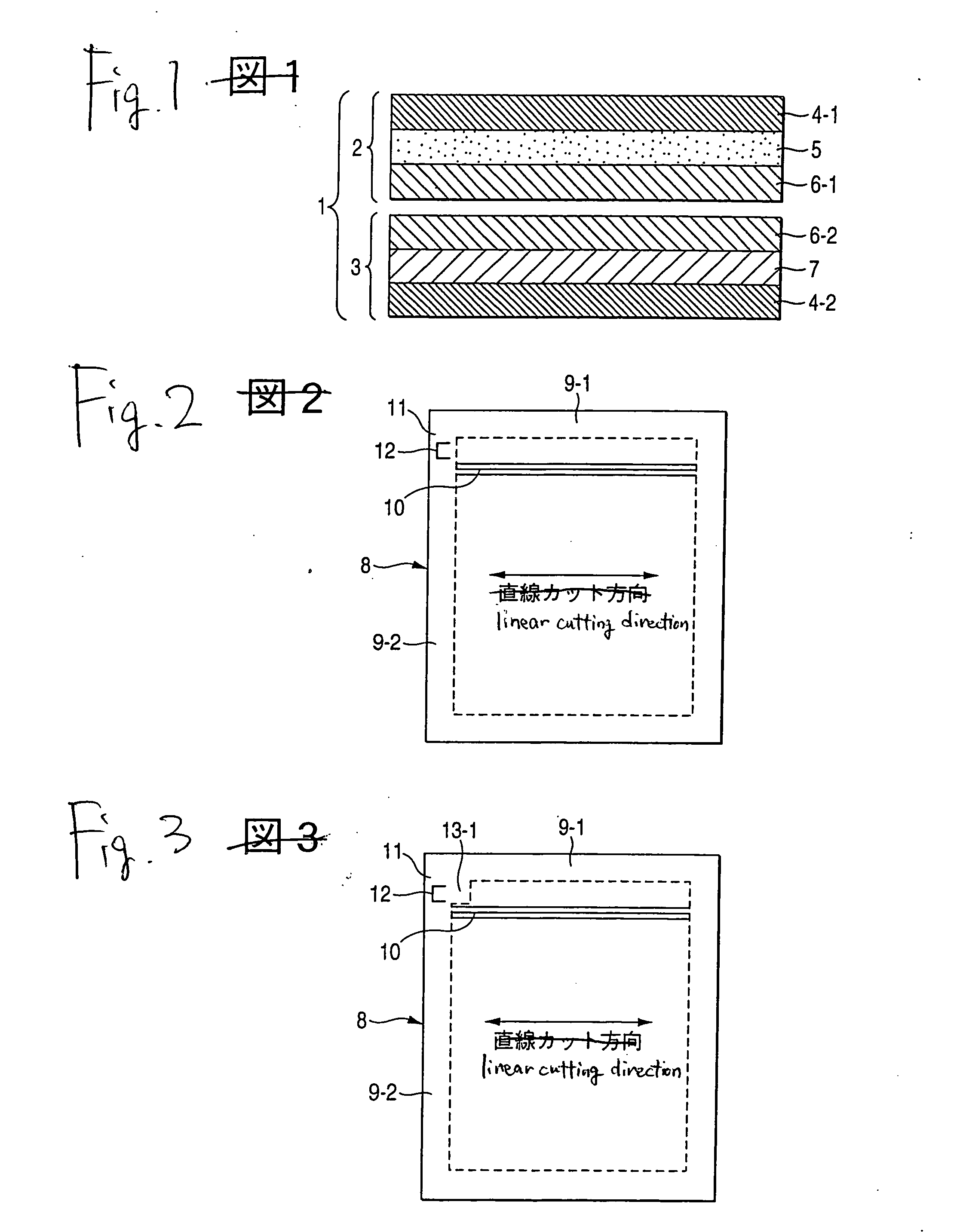

[0057] The front-side laminated film was formed by extruding a low-density polyethylene, which has a density of 0.920 g / cm3 and a thickness of 15 μm, from a T die to laminate together with EMBLET PC, which is a vertically linearly-cuttable polyethylene terephthalate film of 12 μm thickness manufactured by Unitika Ltd. and an aluminum foil of 7 μm thickness via an anchor coating agent by means of sand lamination method, and then extruding the above low-density polyethylene of 300 μm thickness from the T die to laminate on the aluminum foil side. The rear-side laminated film was formed in the same way as above, except that a general polyethylene terephthalate film of 12 μm thickness and without the linearly cuttable property was used in place of the linearly-cuttable polyethylene terephthalate film.

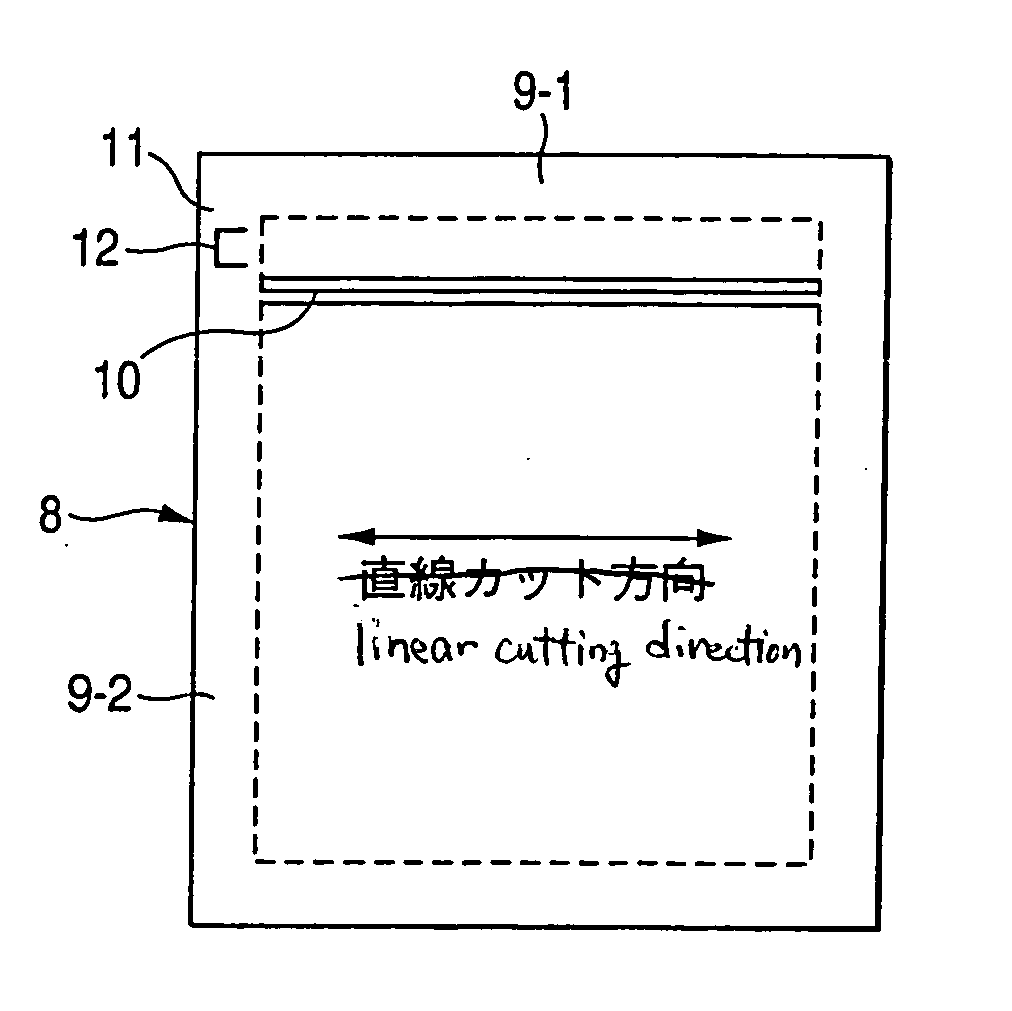

[0058] With a bag forming machine, films serving as the front and rear surfaces of the bag were fed continuously from the biaxial feeder to oppose the low-density polyethylene films to eac...

example 2

[0060] As the front-side laminated film, UNIASLON TB1000 which is a vertically linearly-cuttable polyamide film of 15 μm thickness manufactured by Idemitsu UniTech Co. Ltd. and a linear low-density polyethylene film of 50 μm thickness were laminated by the dry lamination method using a two-liquid polyurethan adhesive. As the rear-side laminated film, a laminated film was formed in the same way as in Example 1, except that a general nylon 6 film of 15 μm thickness and without the linearly cuttable property was used in place of the linearly-cuttable polyamide film. Then, a bag with a zipper was obtained by forming these laminated films into the bag in the same way as in Example 1. In this case, regarding the processed portion, a width of the sealed portion was widened locally to 15 mm by protruding the sealed end portion into the inner side of the packaging bag by 5 mm as indicated by 13-1 in FIG. 3, and the same incision as in Example 1 was provided to the position that is on the inn...

example 3

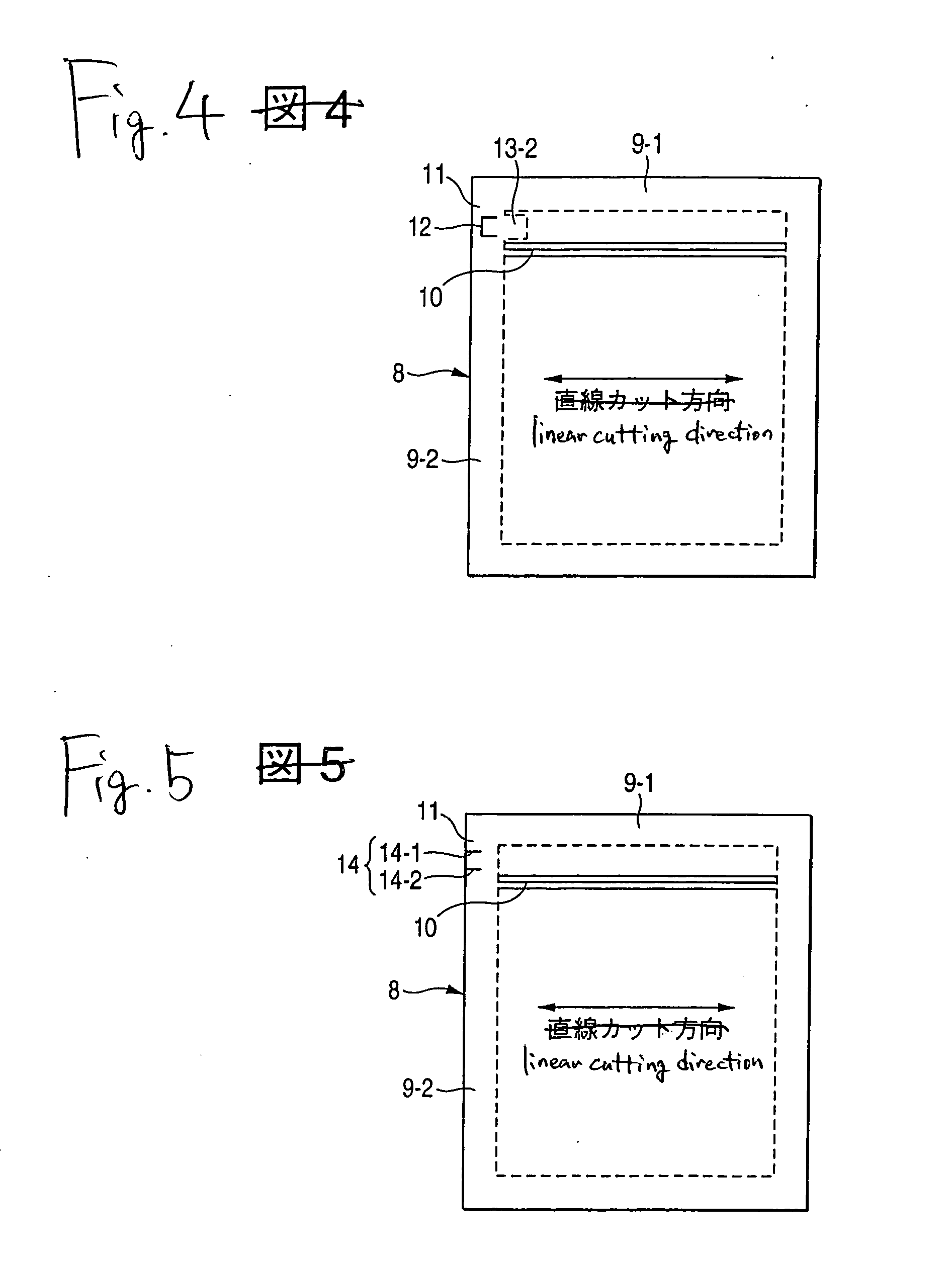

[0062] As the front-side laminated film, the nylon 6 film of 15 μm thickness and without the linearly cuttable property used in the rear-side laminated film in Example 2, a laterally monoaxially stretched polypropylene film YT22 of 25 μm thickness manufactured by Toray Industries, Inc., and a linear low-density polyethylene film of 30 μm thickness were laminated in this order by using a two-liquid polyurethane adhesive. Also, the same rear-side film as in Example 2 was used as the rear-side laminated film.

[0063] Then, a bag whose one side in the flow direction of the bag forming machine was opened and remaining three sides were sealed and in which a longitudinal length was 150 mm, and a lateral length was 100 mm, and a seal width was 10 mm was obtained by forming the laminated films serving as the front and rear surfaces of the bag into a bag by means of the bag forming machine having the biaxial feeder. At this time, a zipper as provided in Examples 1, 2 was not provided.

[0064] A...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com