Fluid ejector pumps

a technology of ejector pumps and fluids, which is applied in the direction of machines/engines, mechanical equipment, transportation and packaging, etc., can solve the problems of increasing turbulence, achieve greater turbulence, increase vacuum or suction, and enhance turbulent mixing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

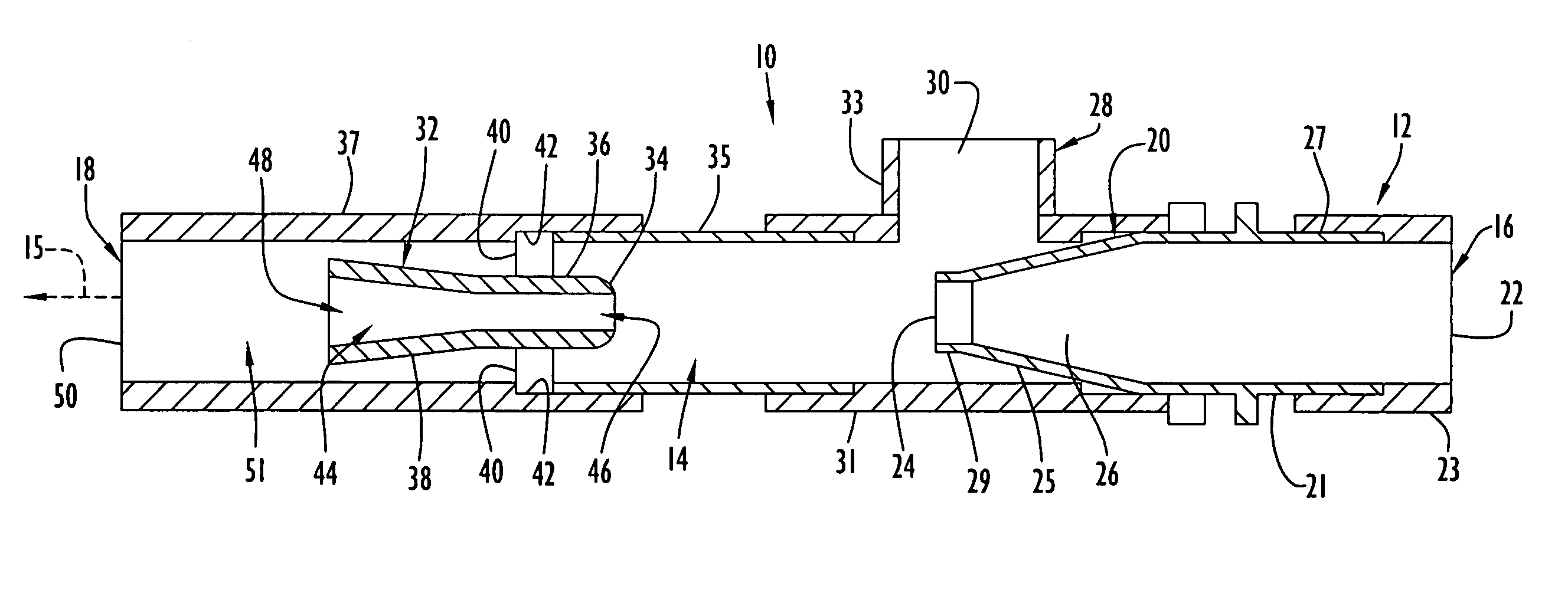

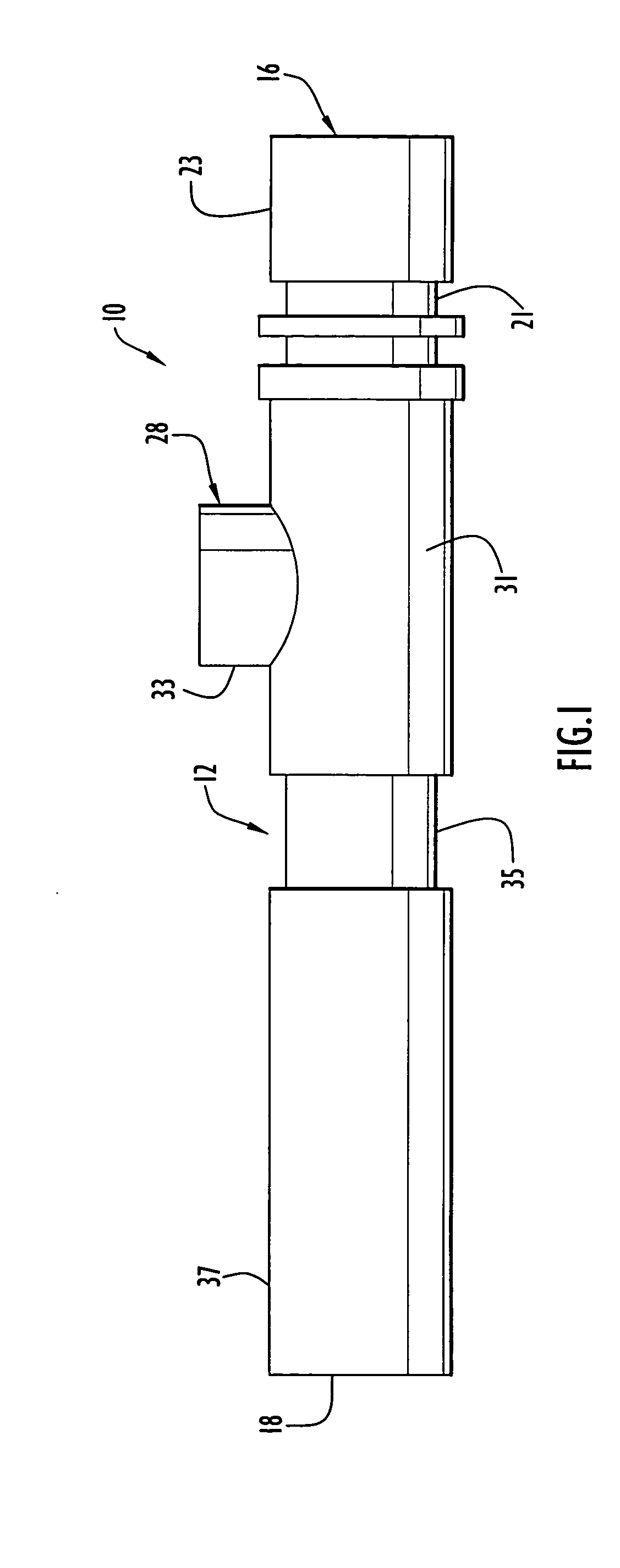

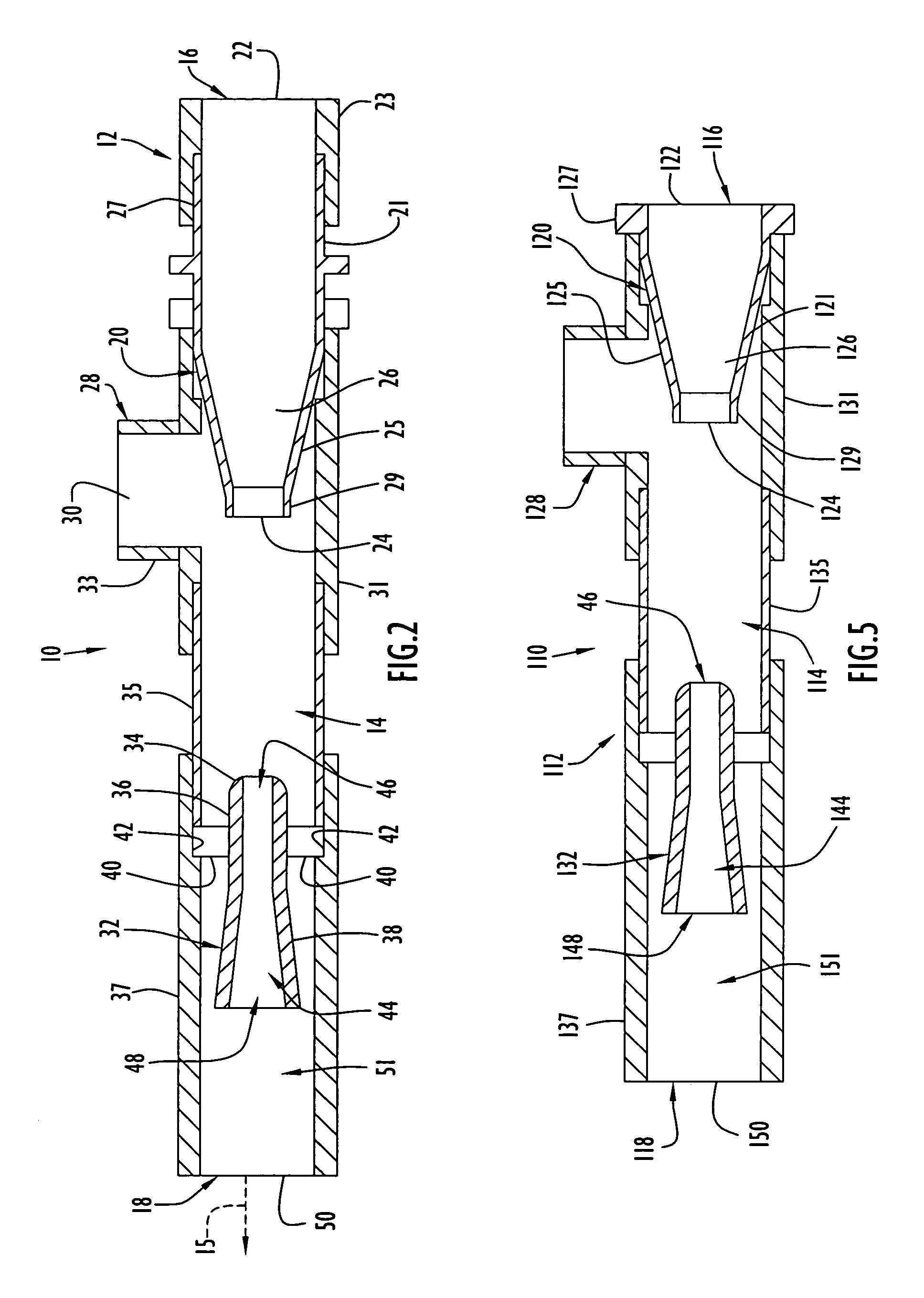

[0021] A fluid ejector pump 10 according to the present invention is illustrated in FIGS. 1 and 2 and comprises an elongate body 12 defining a longitudinally extending flow passage 14 entirely through the body 12. The flow passage 14 has a central longitudinal axis 15. The body 12 and flow passage 14 include an open inlet or downstream end 16 for being supplied with a source of pressurized fluid, such as water, and an open outlet or upstream end 18, opposite the inlet end, through which the fluid is discharged. The wall of body 12 defining flow passage 14 may be formed integrally, unitarily as a single structural part or as a plurality of structural parts connected or assembled in any suitable manner preventing leakage. The inlet end 16 includes a Venturi tube inlet 20 defining a Venturi flow channel therethrough forming a portion of the flow passage 14. The Venturi tube inlet 20 has an entry opening 22 for being supplied with the pressurized fluid, and the Venturi tube inlet extend...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com