Fan unit air flow control

a technology of air flow control and fan unit, which is applied in the direction of process and machine control, liquid fuel engine, instruments, etc., can solve the problems of exacerbated noise problem in clean room facilities, inability to reduce noise to a satisfactory level, and excessive so as to reduce the noise of the fan unit and reduce the turbulence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] In the following description, numerous specific details are set forth such as, for example, guides and baffles, in order to-provide a thorough understanding of the invention. In other instances, well-known components such as, for example, the motors for the fan blower and ducts connected to the fan units, are not shown and / or described in order not to obscure the invention.

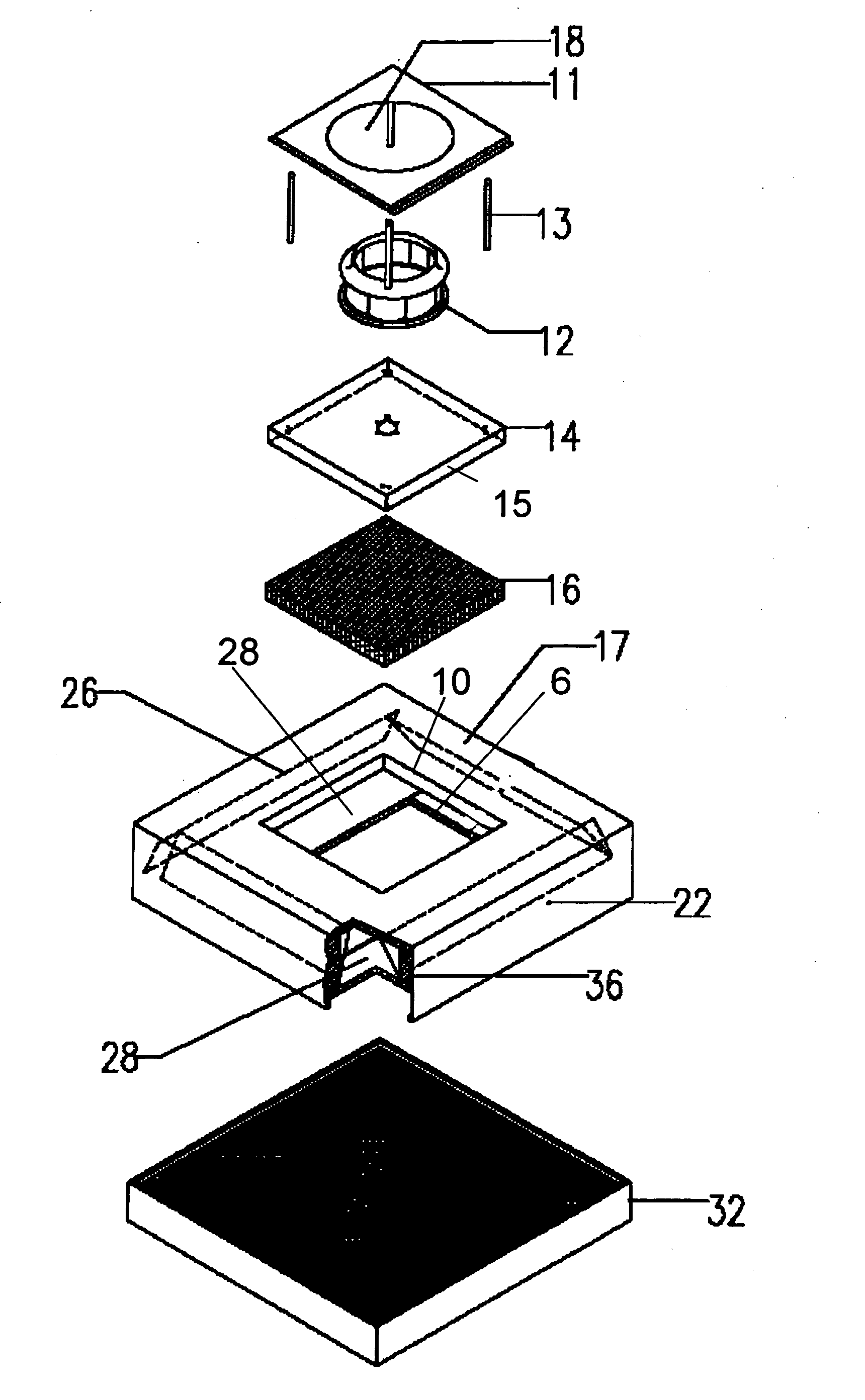

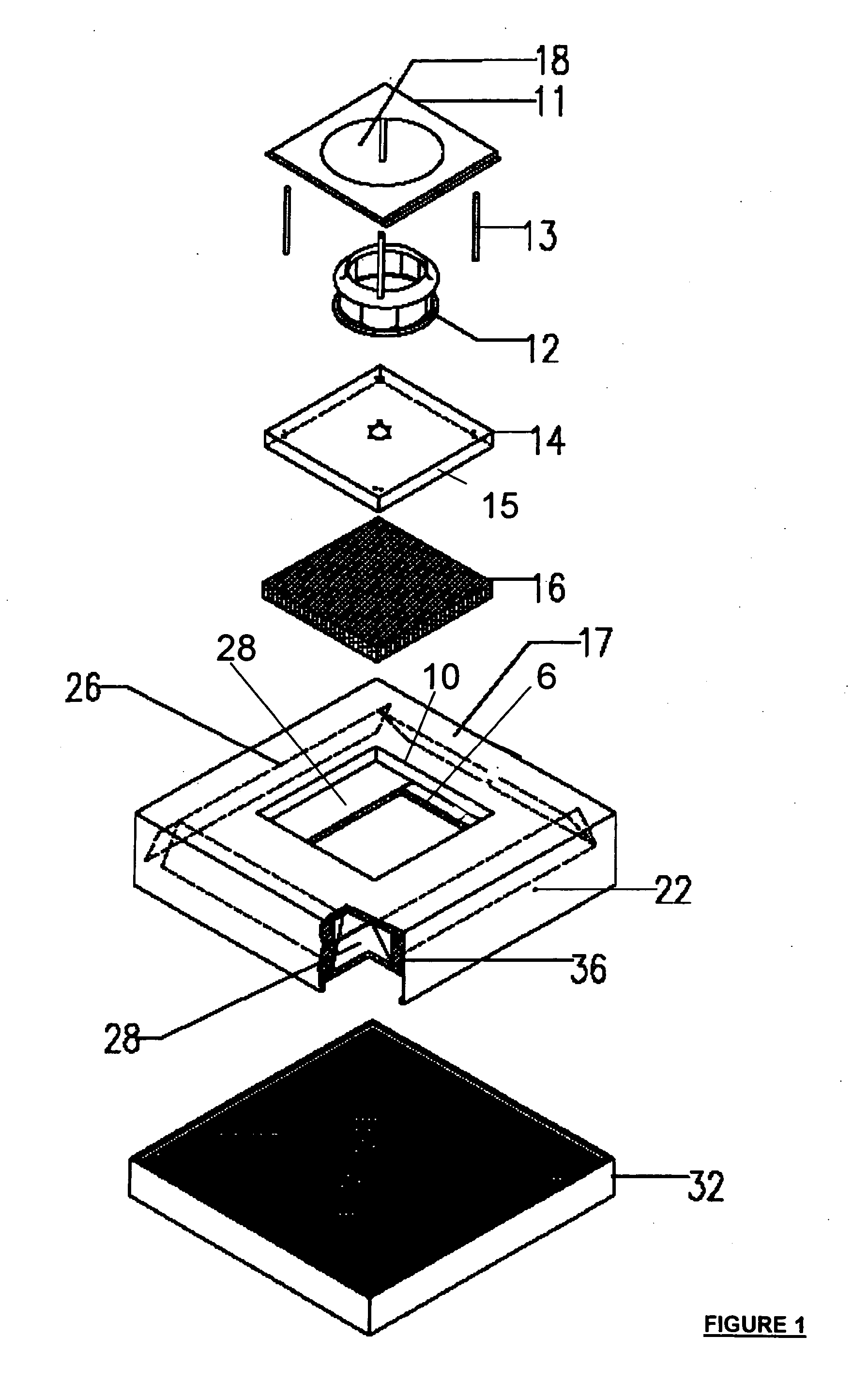

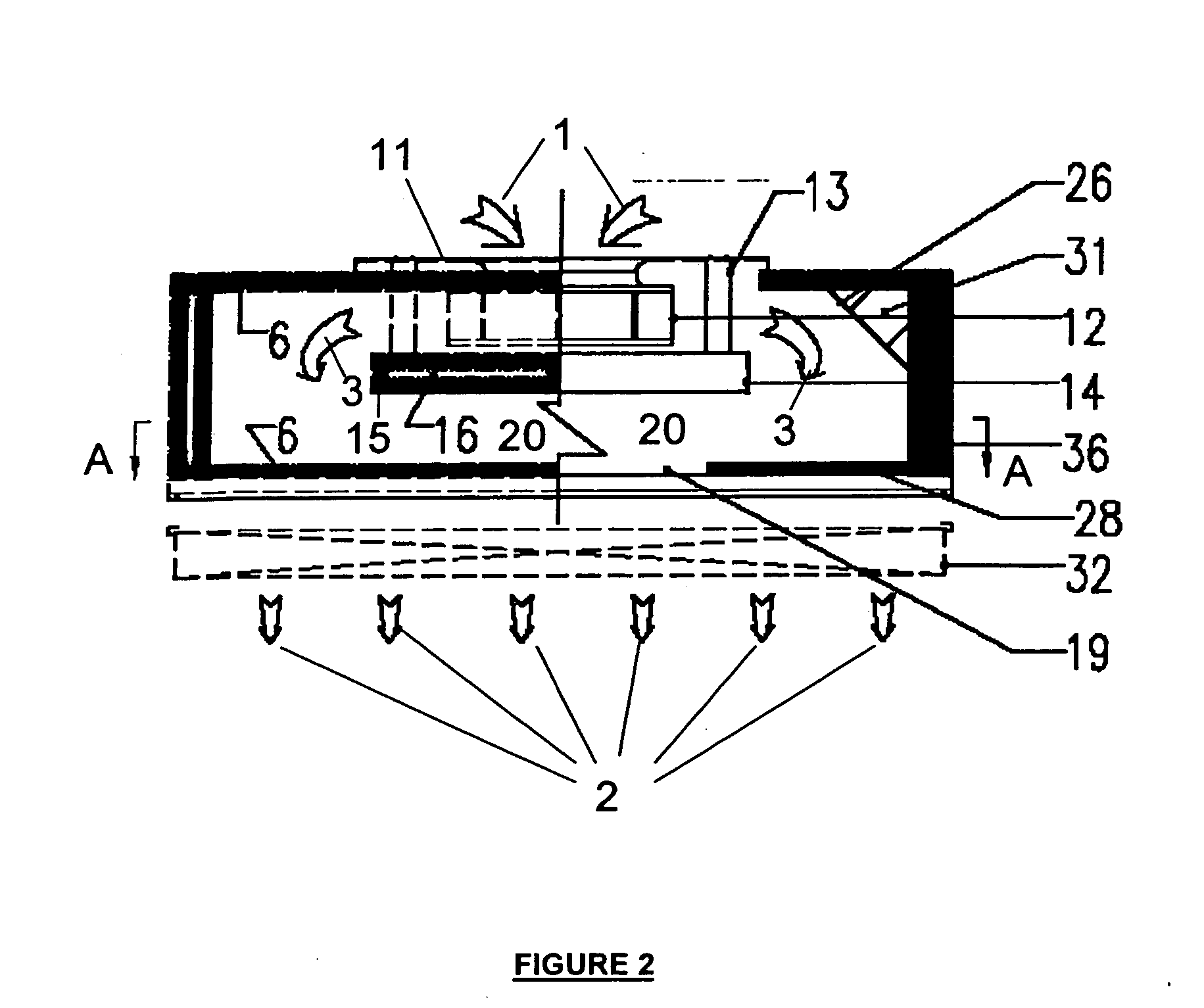

[0029]FIG. 1 is an exploded, front, perspective view of a preferred embodiment the present invention integrated as part of a fan unit. The fan unit comprises four mutually perpendicular side walls 22, and an annular top 17 having a central opening 10. Although the fan unit is shown as being square in shape, it may be of any suitable shape such as, for example, cylindrical, triangular, rectangular, pentagonal, octagonal, and so forth.

[0030] The central opening 10 is shown as being square. It also may be of any suitable shape such as, for example, round, triangular, rectangular, pentagonal, octagonal, and s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com