Stacking system for injection molded articles

a technology of injection molded articles and stacking systems, which is applied in the field of stacking and flexible articles, can solve the problems of insufficient stability of stacks for further handling and transfer, and new challenges in post-mold handling of these containers and their accessories, and achieve the effect of effectively handling volumes of such articles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The advent of high-speed robotic parts removal systems, for example the Viper SE (trademark) robots manufactured by Ventax Robot Inc. of Ayr, Ontario, Canada, has made maintaining the orientation of the parts throughout the transfer to the post mold stacking facility an affordable and viable option. A particularly elegant way to stack parts, presented by the end-of-arm tool of such a robotic parts removal system just outside the mold of an injection molding machine, is to hand over the parts directly into the stacking device of the invention, creating either as many stacks as there are cavities in the mold, e.g. 16, or a fraction of that number, e.g. 8 or 4, if the cycle time and other circumstances allow for multiple, sub-sequential hand-over actions. The stacks may be built up either vertically or horizontally or in any inclination, depending on favorably catering to other post-mold operations, i.e. printing, assemblies, packaging, etc.

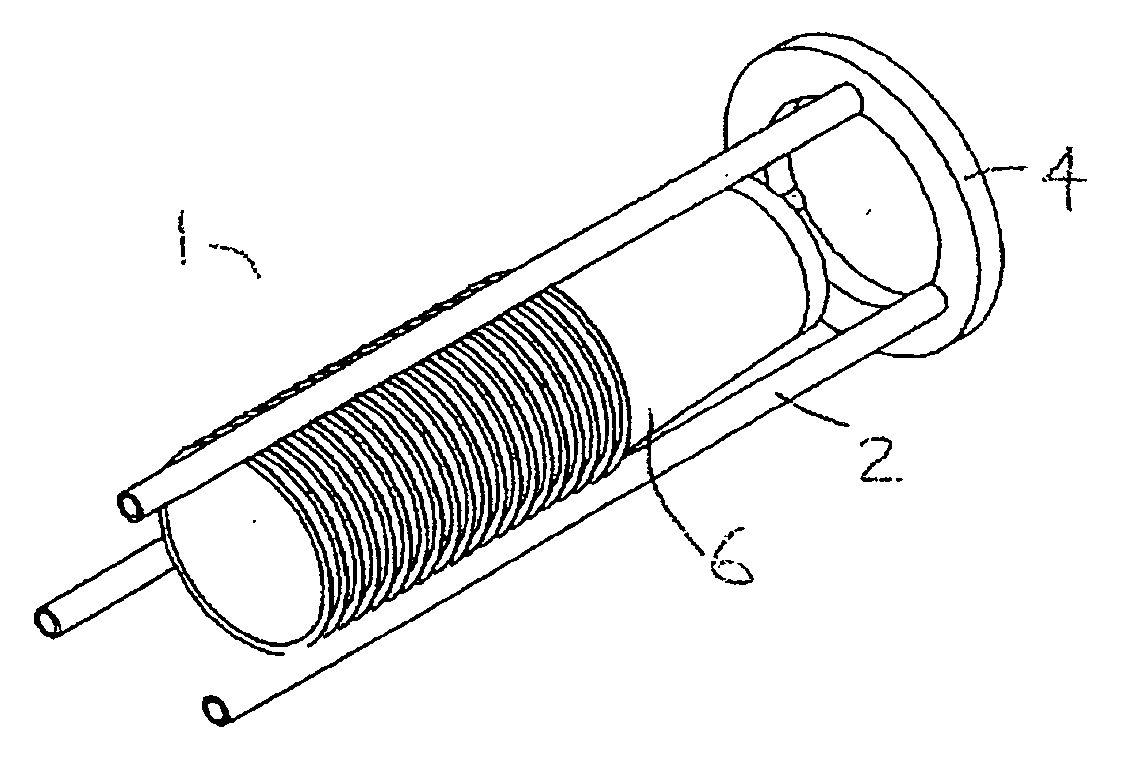

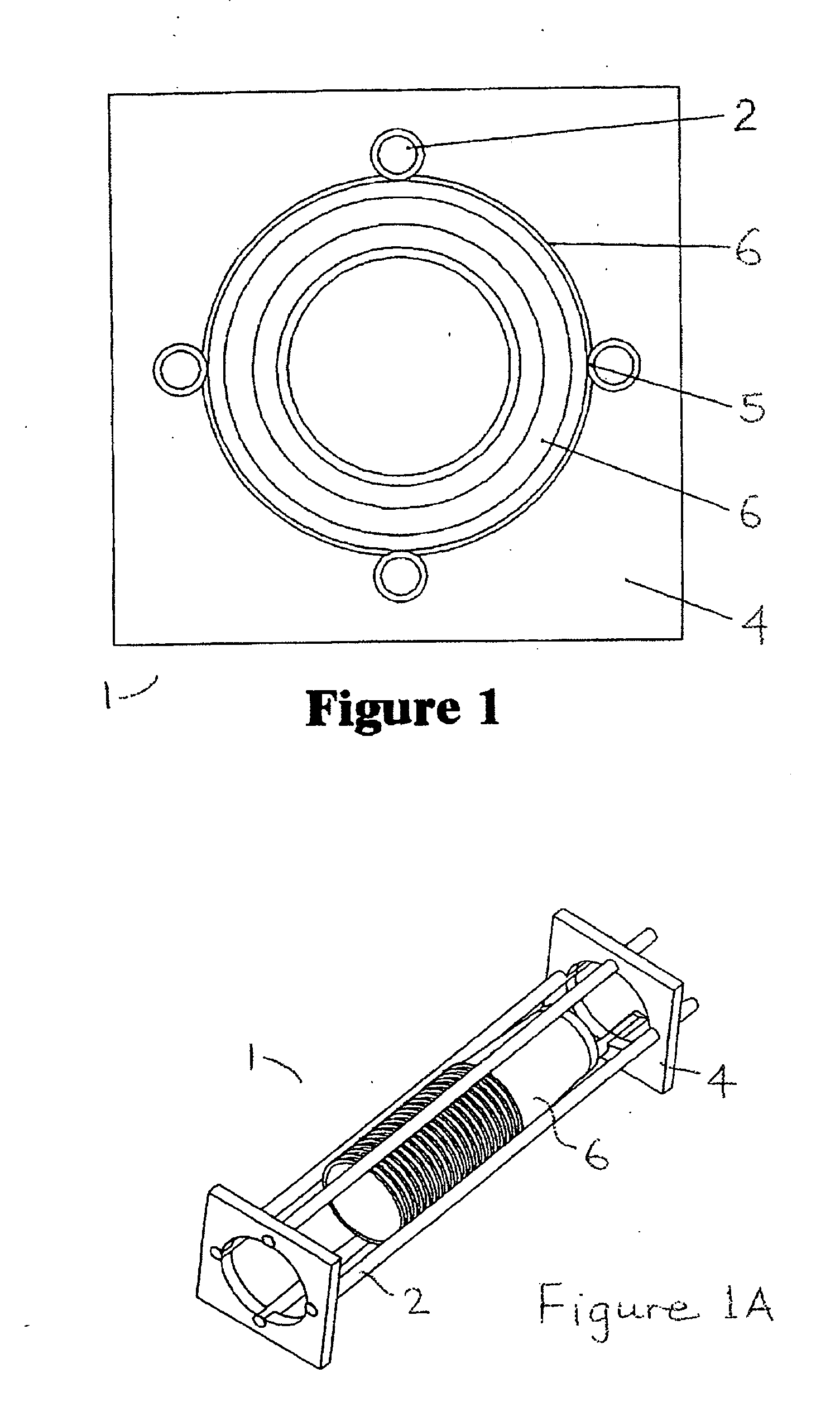

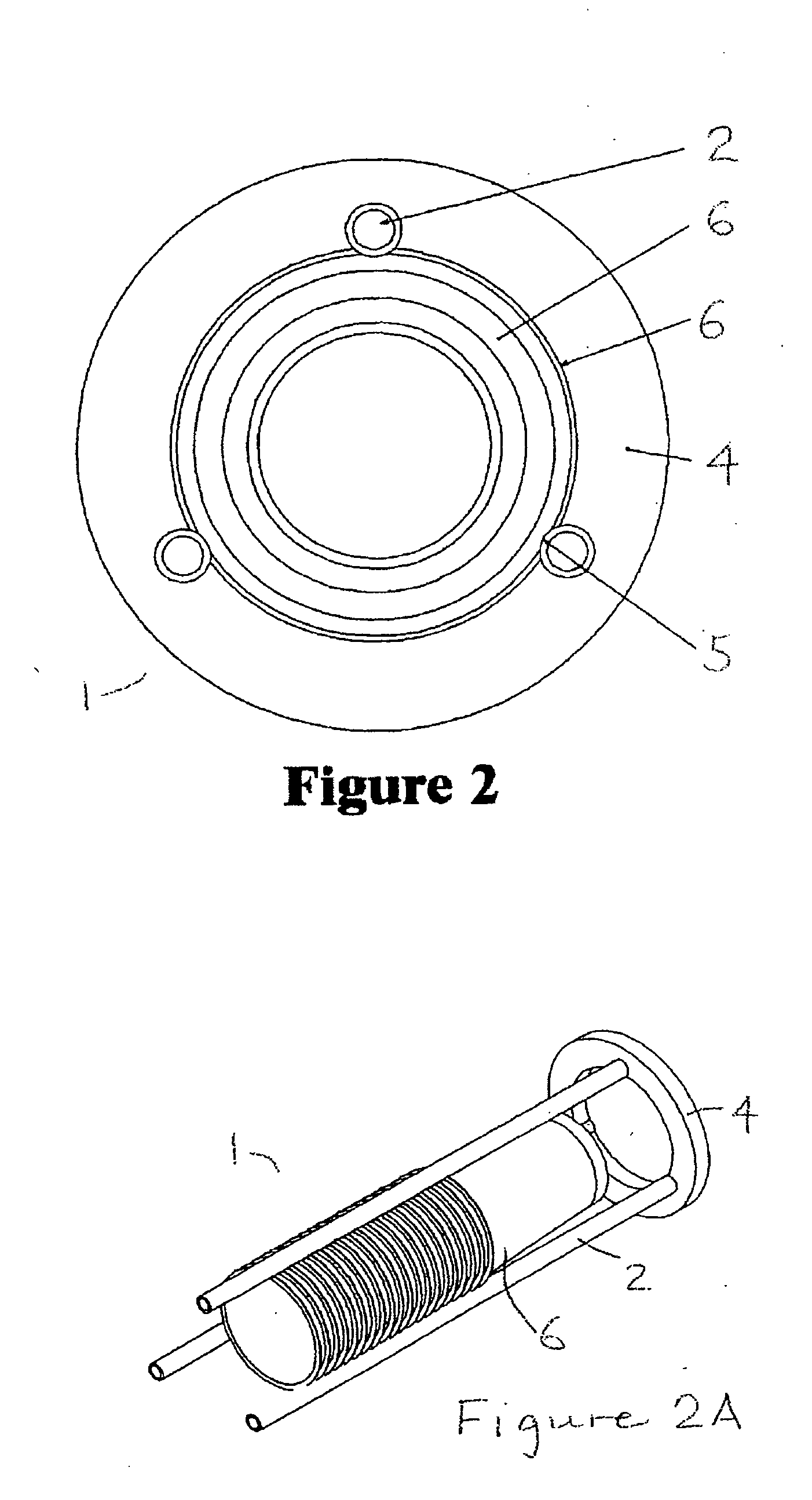

[0023] At the core of the invention i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com