Hermetically sealed container for large-sized precision sheet (semi-) product

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

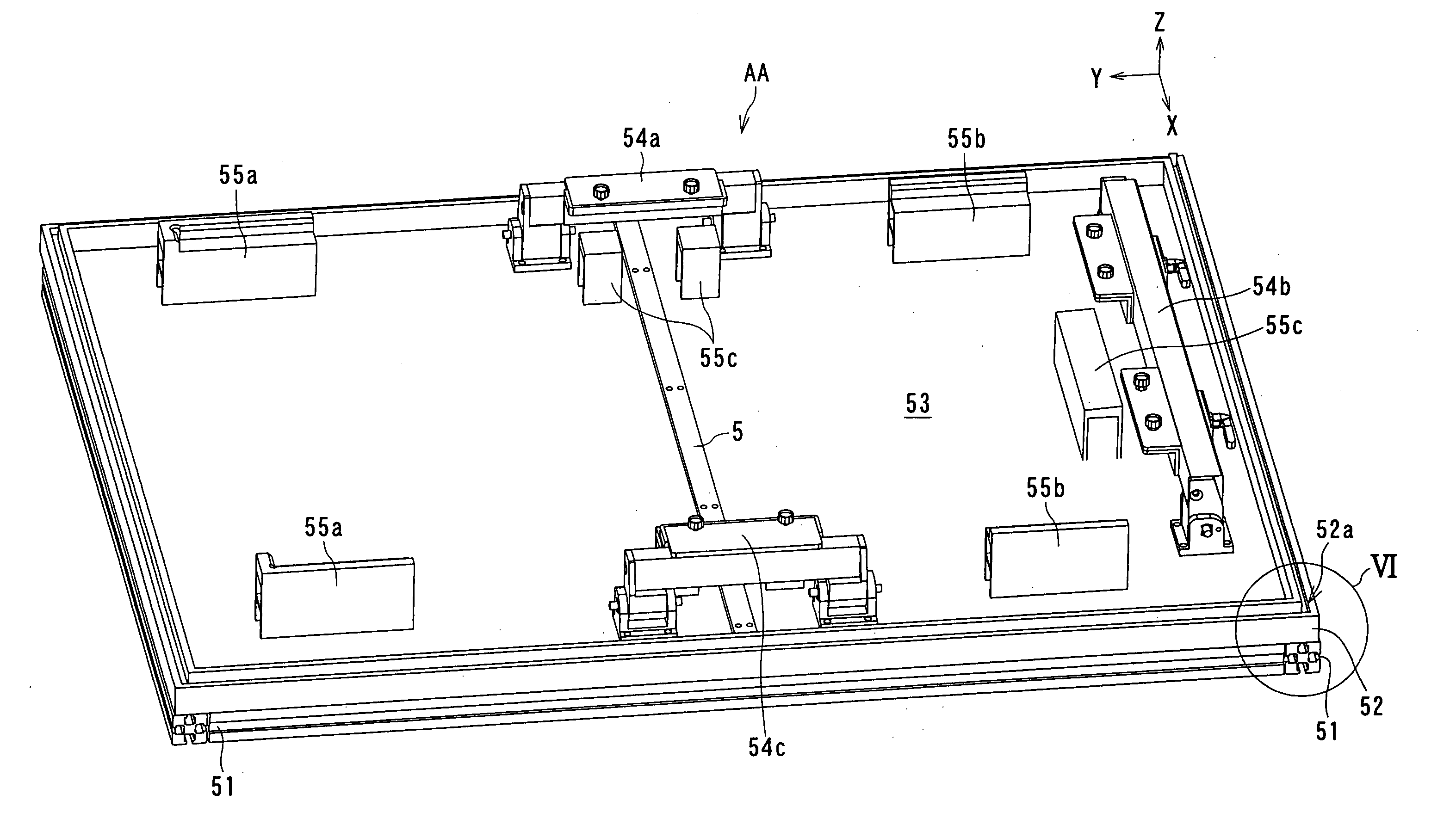

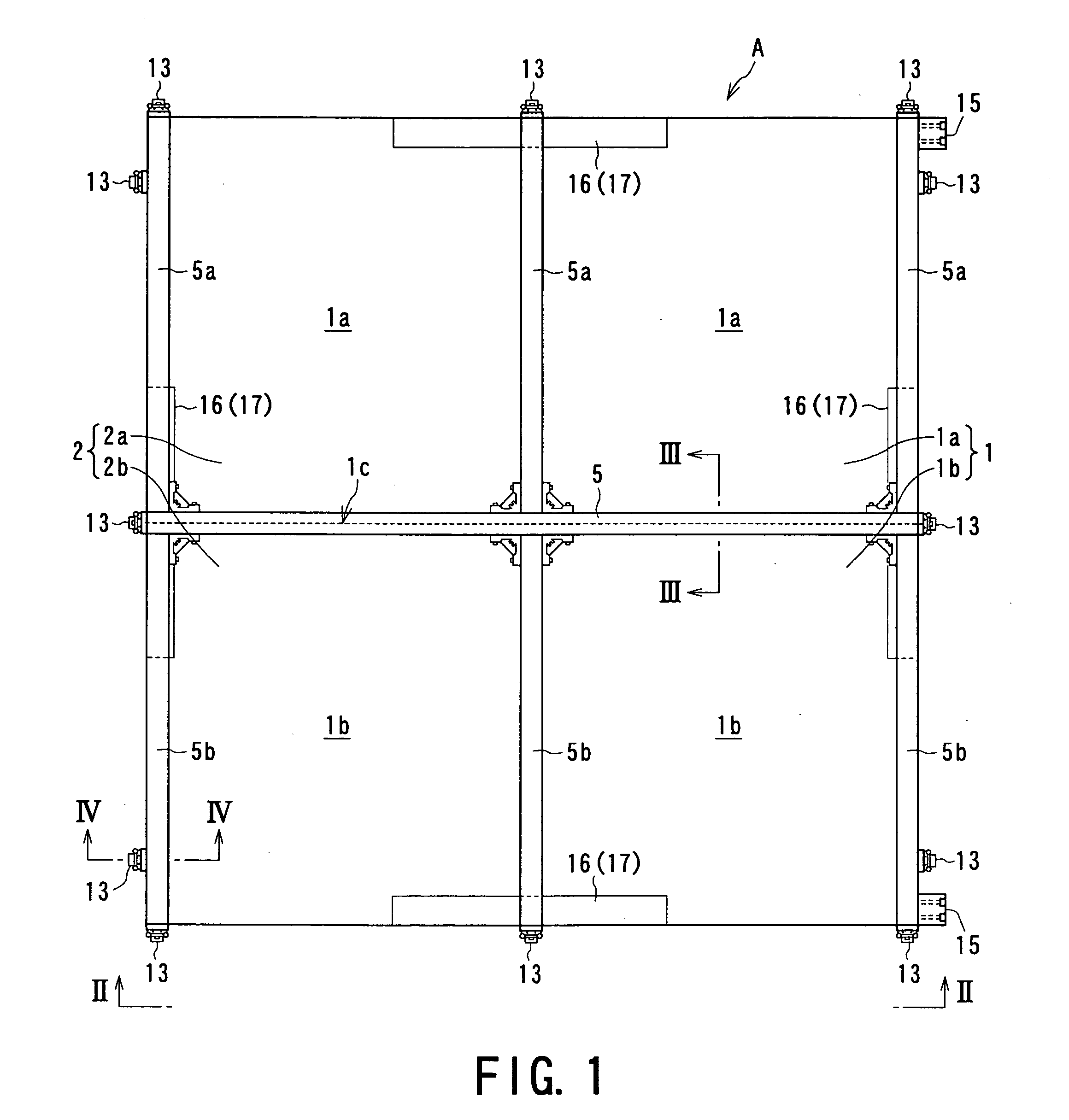

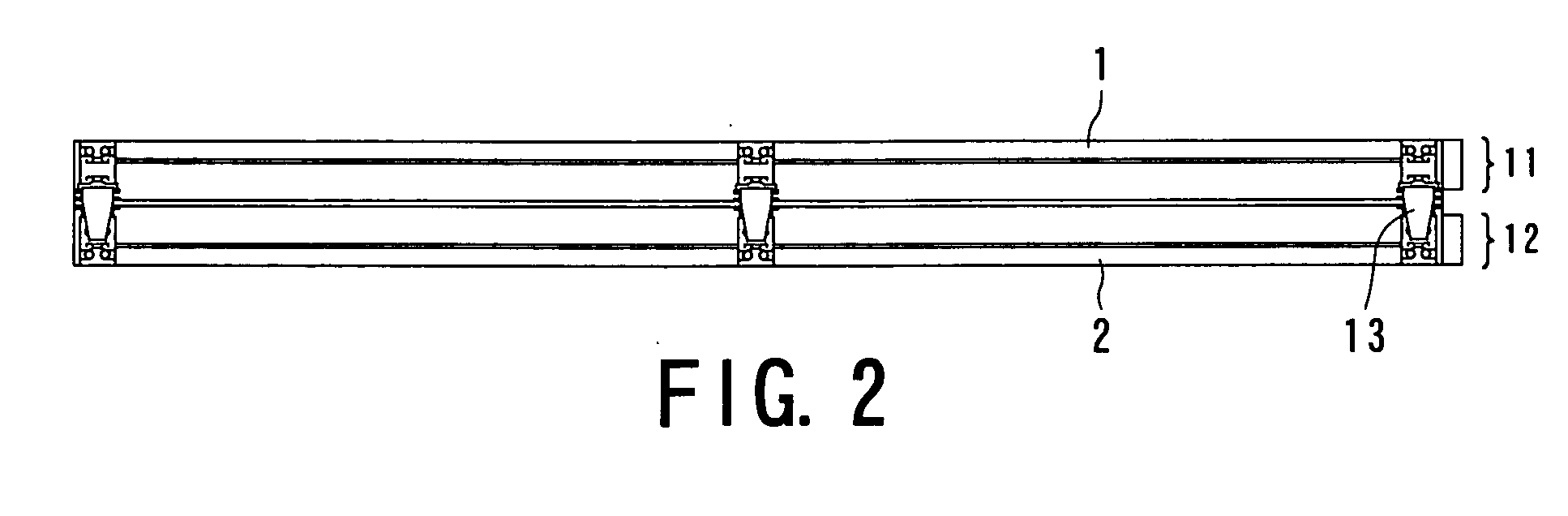

[0016]FIG. 1 is a plan view of a container A (having outer sizes of ca. 1300 mm×ca. 1300 mm×ca. 100 mm in depth) of a horizontal type (i.e., a type of structure wherein a precision sheet (semi-)product is accommodated in a position generally parallel to an abutting plane between sealing peripheries of a main body and a lid member) for a precision sheet (semi-)product (a photomask for a liquid crystal display (LCD) formed on a generally rectangular quartz-made substrate having sizes of L(longitude).: ca. 1200 mm×T(transverse): ca. 1200 mm×ca. 5 mm in thickness in this embodiment, hereinafter sometimes referred to as a “(semi-)product sheet”). FIG. 2 is a front view as viewed in a direction of arrows II-II, and FIGS. 3 and 4 are partial sectional views taken along a III-III line and a IV-IV line, respectively, shown in FIG. 1. The container A includes a lid member 11 principally composed of a ceiling plate 1 comprising two resin sheets 1a and 1b which are joined with each other at a m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com