Solar cell and method for producing the same

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

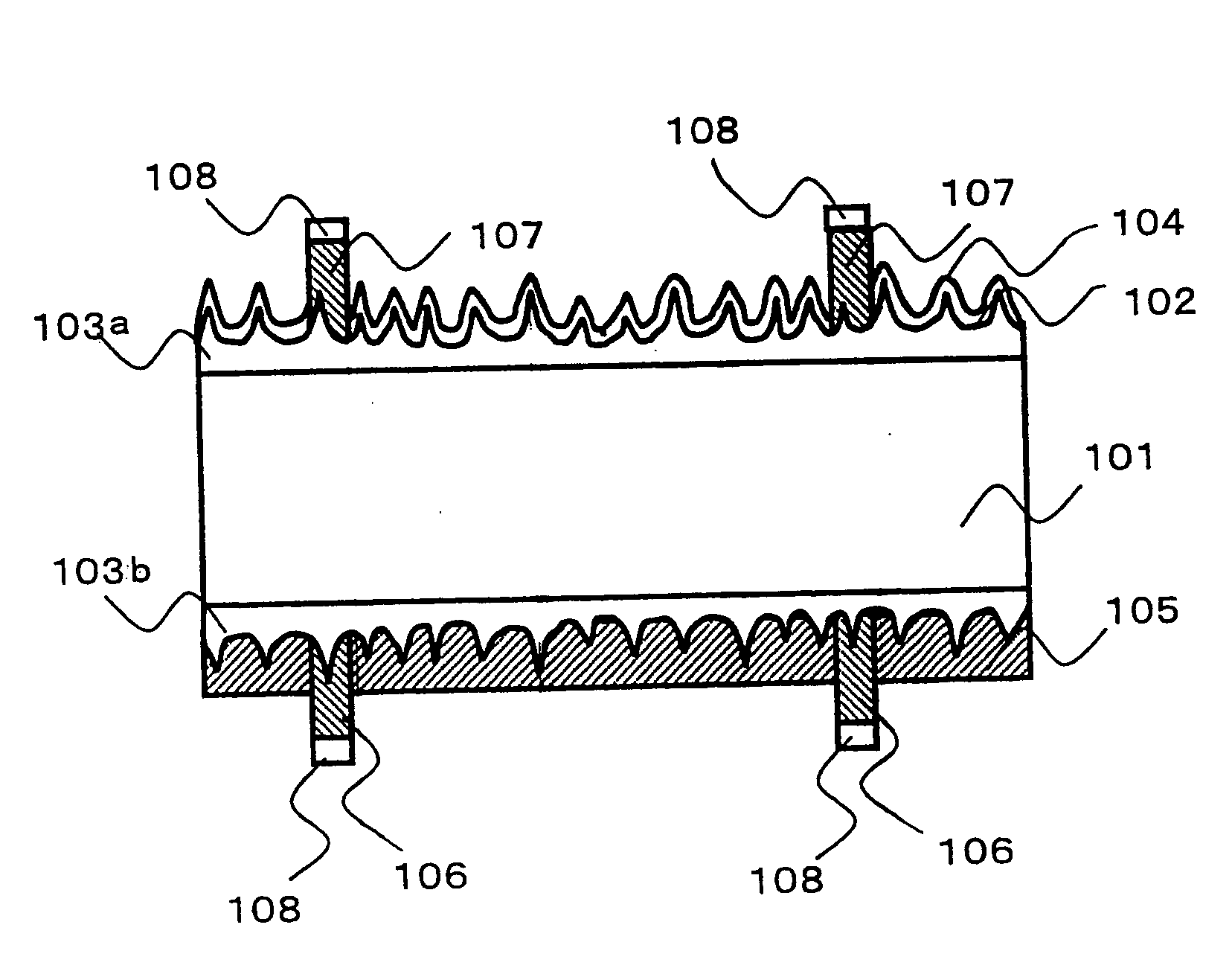

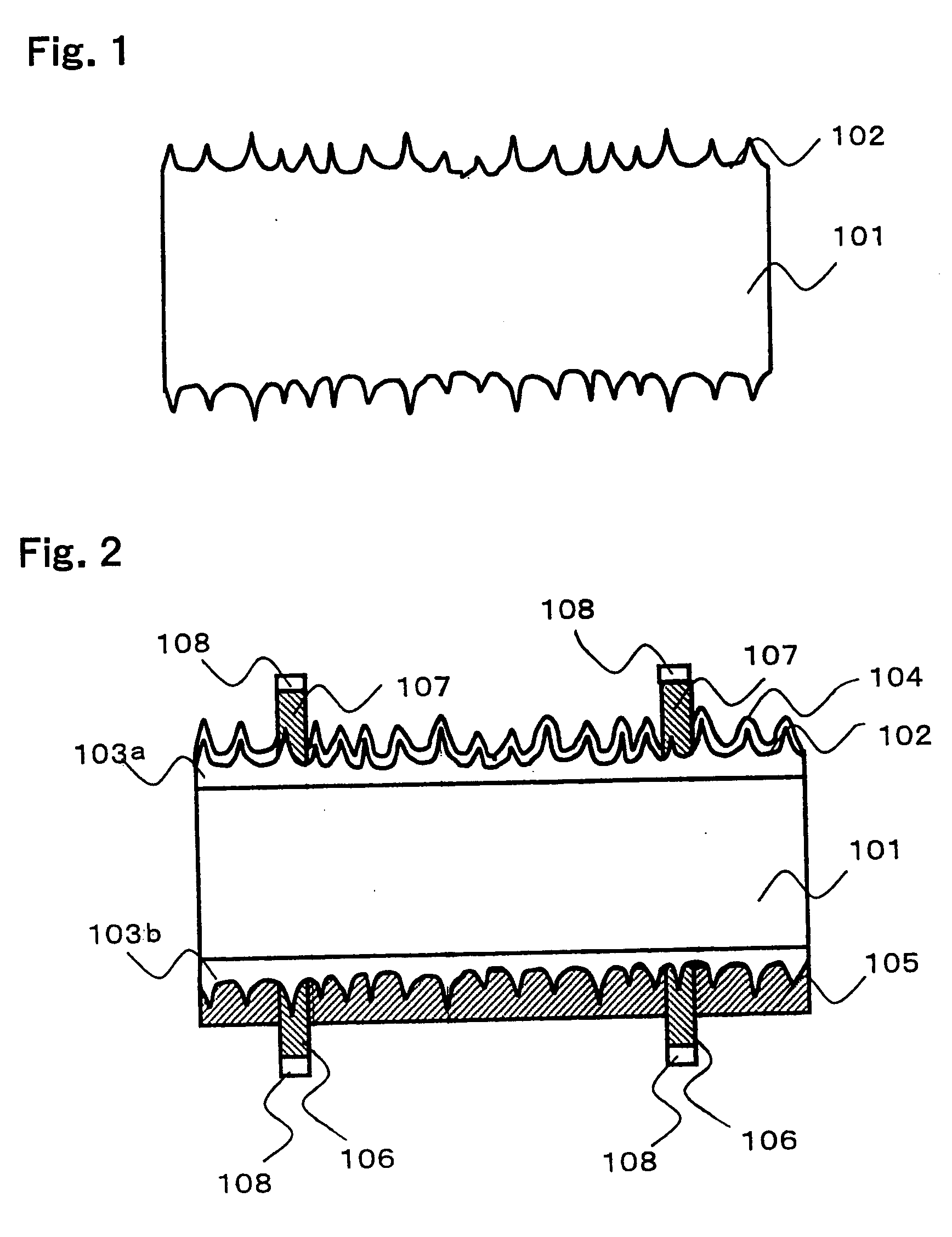

Image

Examples

embodiment 1

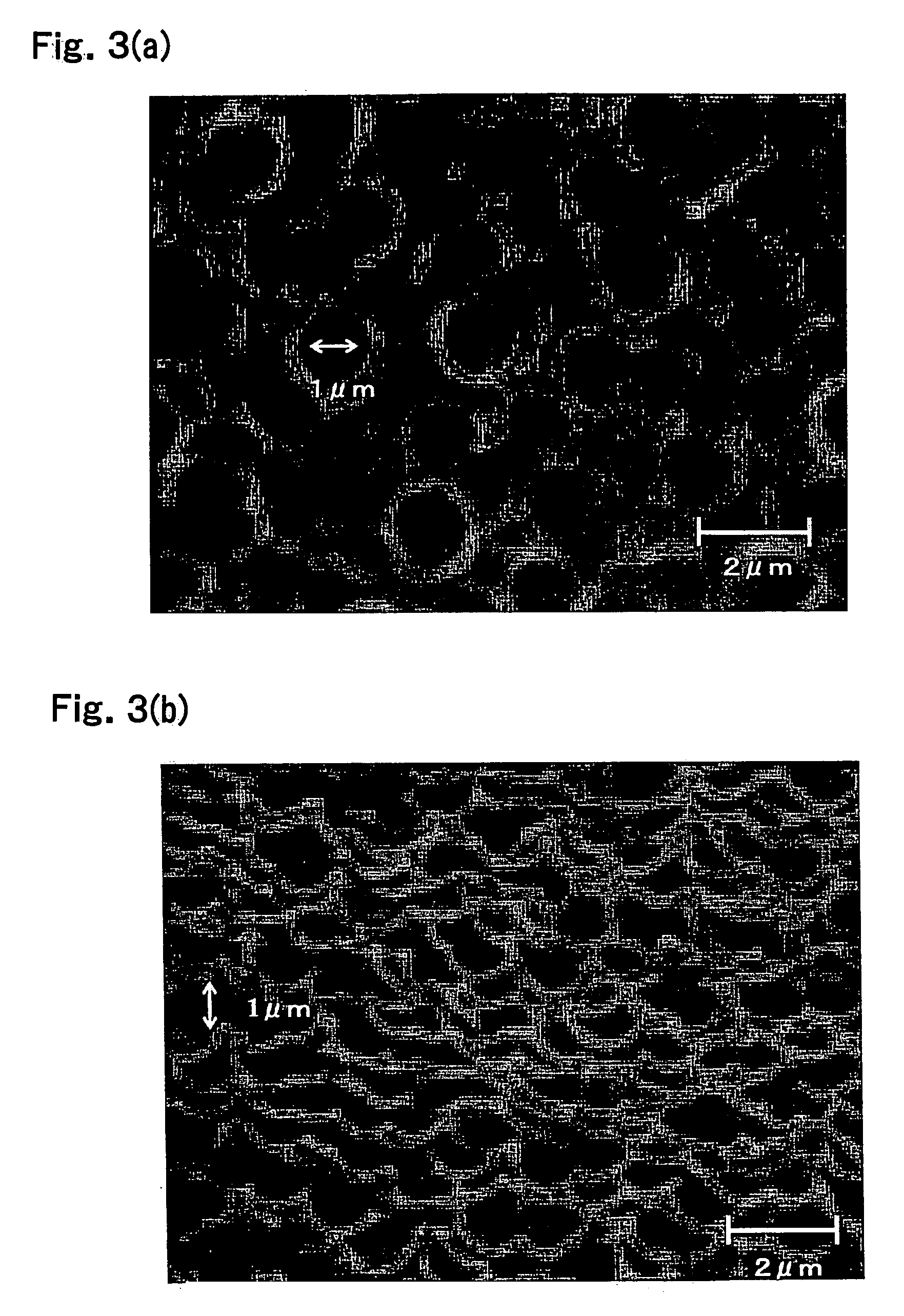

[0072]FIG. 3(a) and FIG. 3(b) are a top SEM image and a 60-degree oblique SEM image, respectively, of a plurality of depressions having a first type of configuration and size formed in surfaces of the substrate of

embodiment 2

[0073]FIG. 4(a) and FIG. 4(b) are a top SEM image and a 60-degree oblique SEM image, respectively, of a plurality of depressions a second type of configuration and size formed in surfaces of the substrate of

embodiment 3

[0074]FIG. 5(a) and FIG. 5(b) are a top SEM image and a 60-degree oblique SEM image, respectively, of a plurality of depressions having a third type of configuration and size formed in surfaces of the substrate of

[0075]FIG. 6 is a graph showing the surface reflectivity of the polycrystalline silicon substrates according to Embodiments 1 to 3 and the comparative example.

[0076] Shown in Table 1 are IV characteristics of the solar cells according to Embodiments 1-3 and the comparative example. In Table 1, Jsc indicates short-circuit current, Voc indicates open-circuit voltage and FF indicates fill factor and Pmax indicates maximum power.

TABLE 1Jsc (mA / cm2)Voc (V)FFPmax (W)Embodiment 130.60.5950.7782.19Embodiment 229.90.5940.7612.11Embodiment 329.70.5910.7692.11Comparative Example29.90.5950.7382.06

[0077] According to Table 1, the solar cell of Embodiment 1 is higher in all of the parameters except open-circuit voltage when compared to that of the comparative example. Further, the cel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com