Surface treated particulated polymeric matrix for forming an exposed surface of a weatherseal

a technology of surface treated polymeric matrix and weatherseal, which is applied in the field of vehicle weatherseal, can solve the problems of significant stress on the seal between the glass panel and the vehicle, the flocking process is relatively complicated, and the glass panel is not ready to open and close. it can achieve a different appearance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

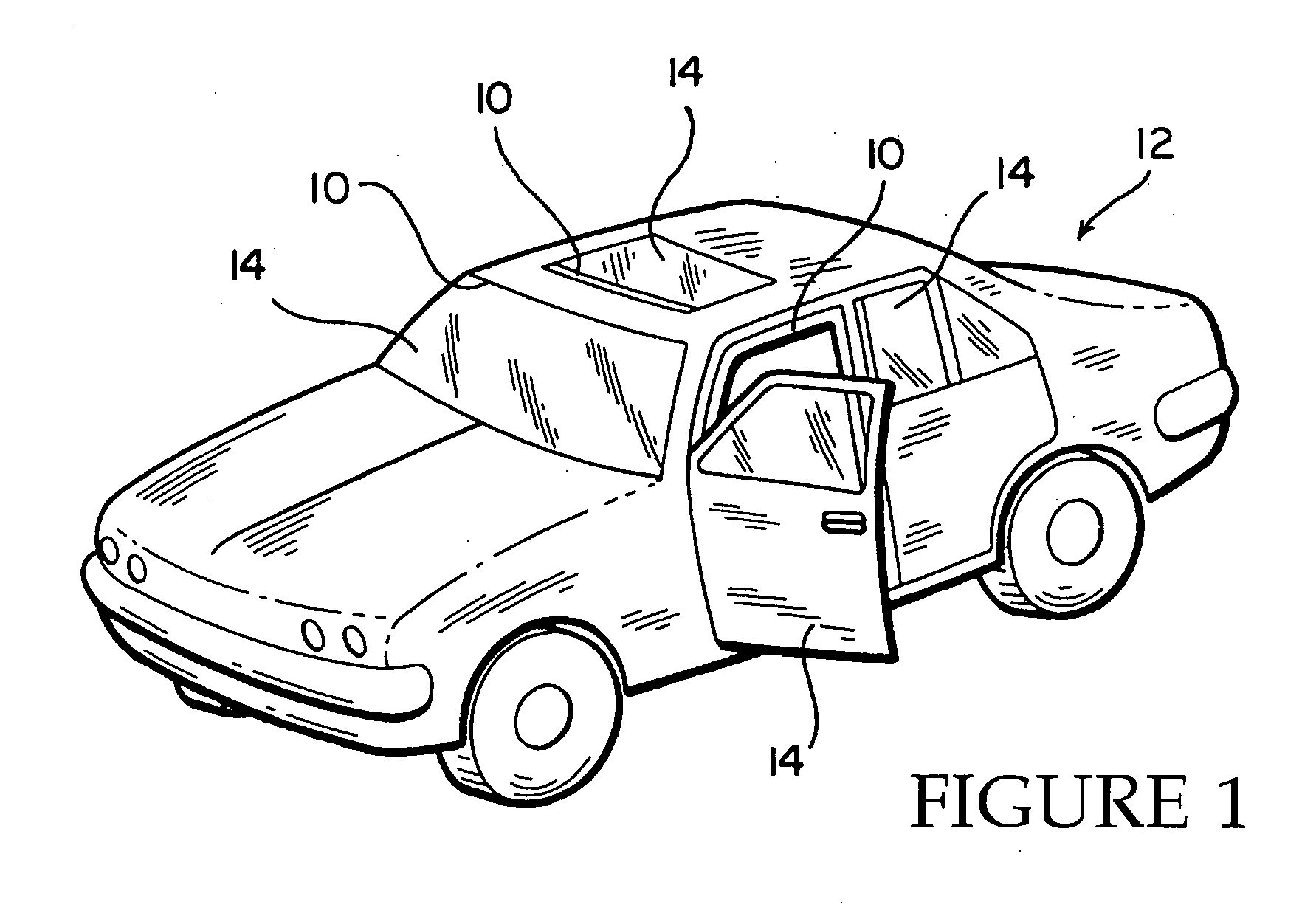

[0023] Referring to FIG. 1, the weatherseal 10 of the present invention may be employed at various locations on a motor vehicle 12. The weatherseal 10 may be located between a portion of the frame of the vehicle 12 and a moveable portion such as a door or window panel 14. Alternatively, the weatherseal 10 may be located between portions intended to be fixed such as a windshield or a rear window and the vehicle 12.

[0024] Although the term panel 14 is used to describe a window, it is understood that panel may be any of a variety of materials such as, but not limited to glass, plastics, composites, or metal, which may be coated, painted, surface treated or bare. Therefore, the panel 14 may include glass such as windows, and metal or composites such as vehicle body parts, which may be intended to be stationary or movable with respect to the panel.

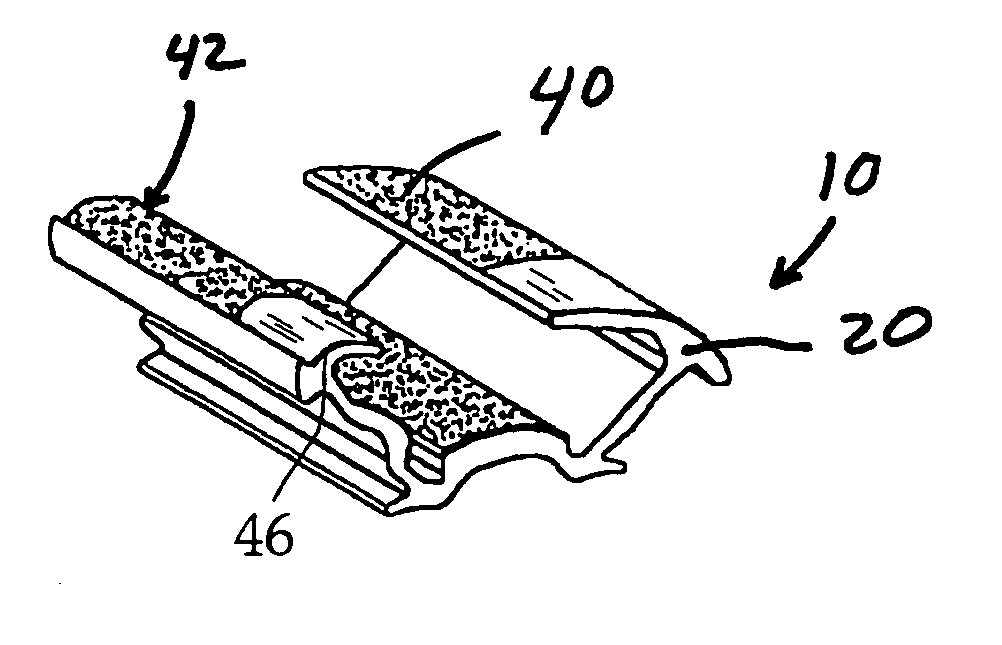

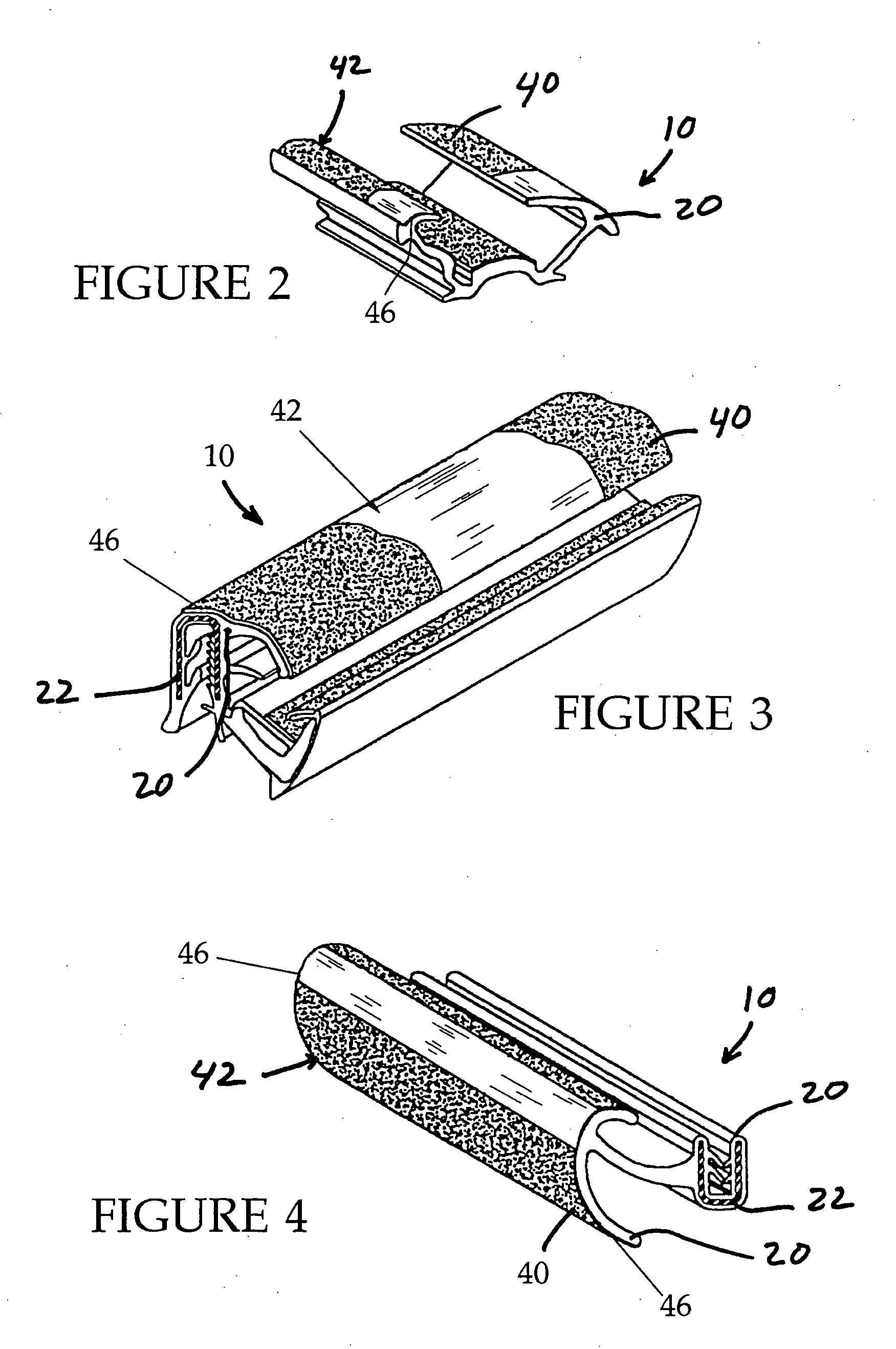

[0025] The weatherseal 10 may have any of a variety of cross sectional profiles, such as, but not limited to “U”, “J”, “C” or “L” shaped. Ty...

PUM

| Property | Measurement | Unit |

|---|---|---|

| distance | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com