Standing wave particle beam accelerator

a particle beam accelerator and standing wave technology, applied in accelerators, klystrons, electric discharge tubes, etc., can solve the problems of not being able to achieve the prescribed/desirable level of output radiation yield associated with the generated electron beam, adding substantial weight to existing accelerators,

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example

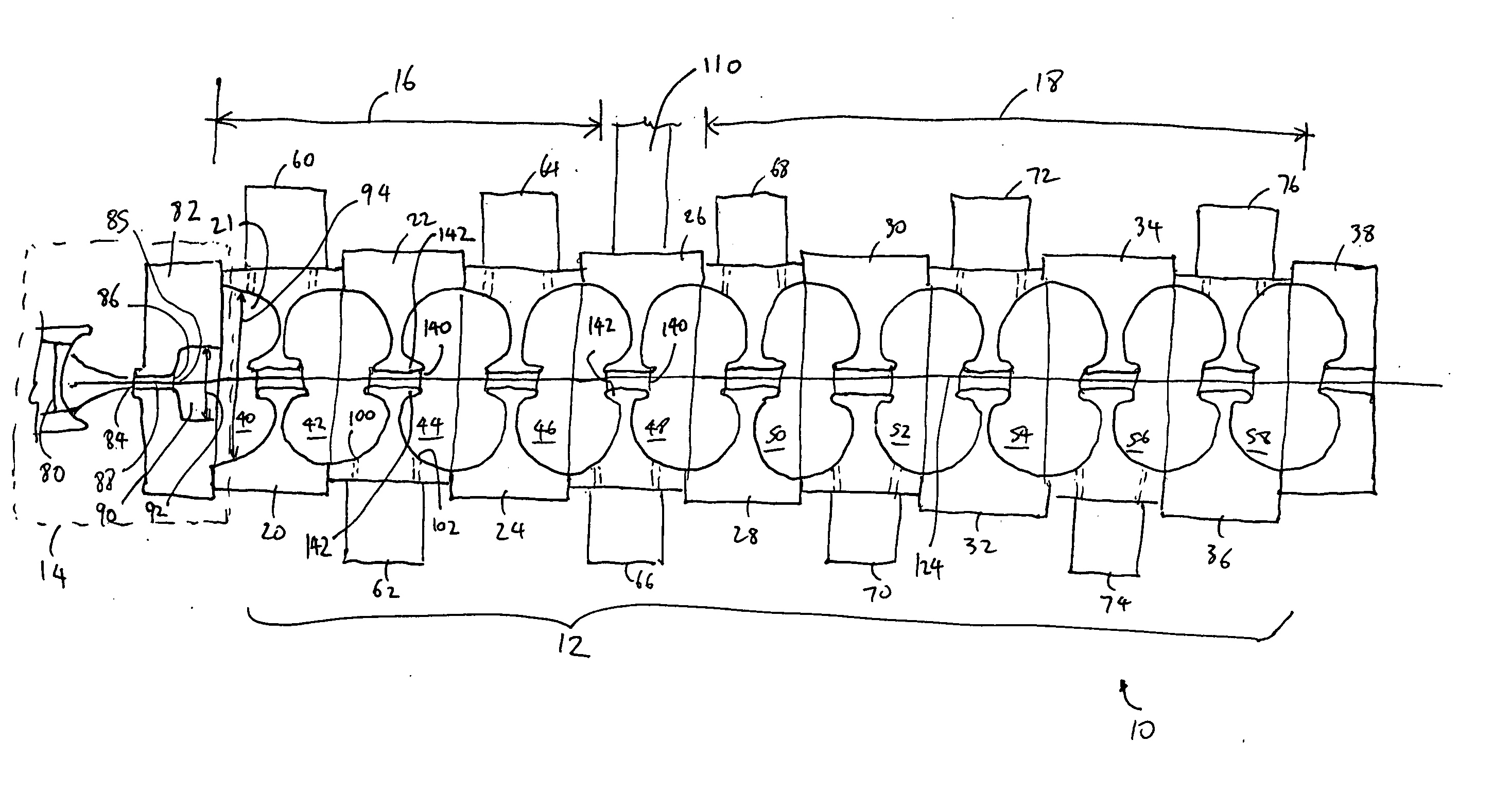

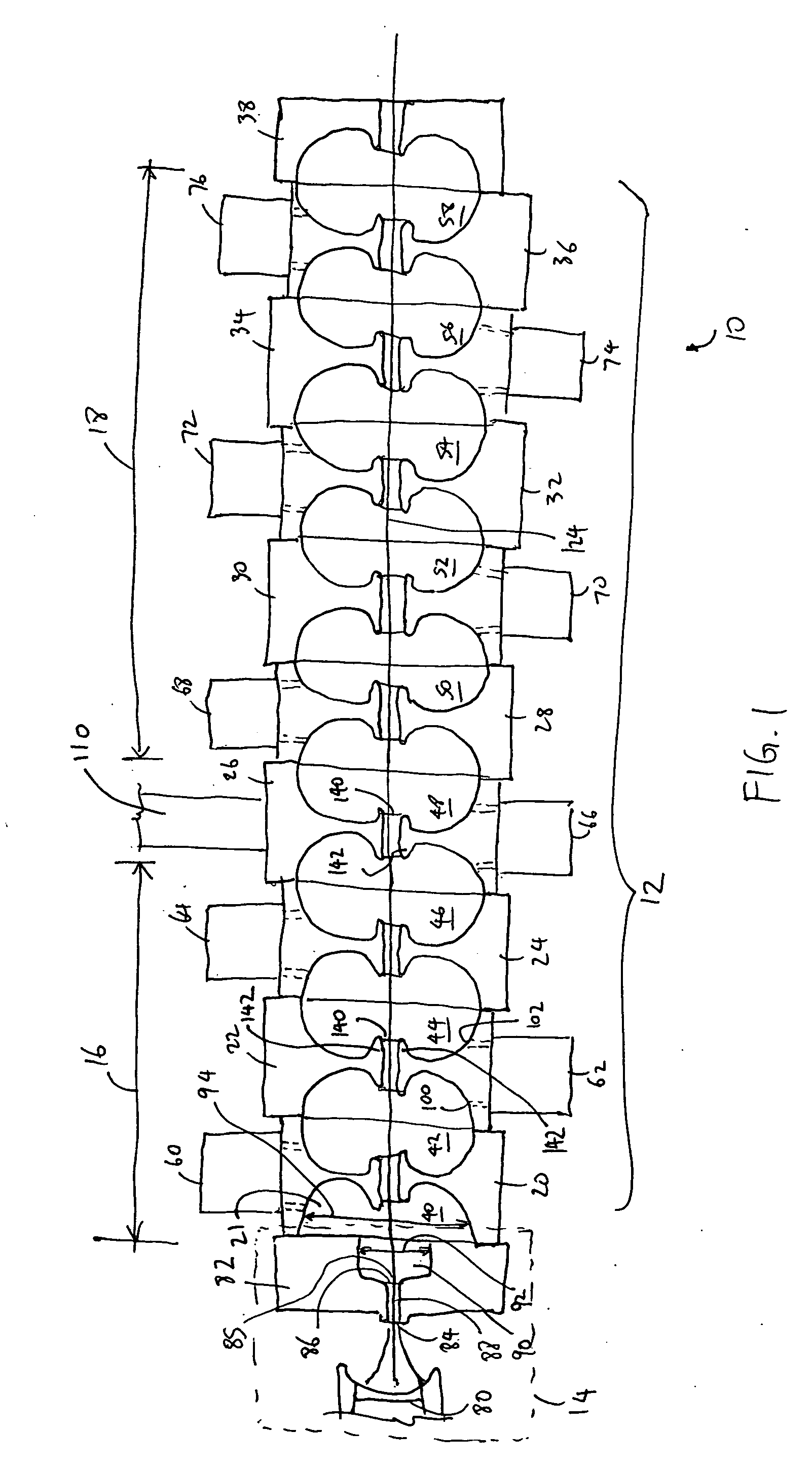

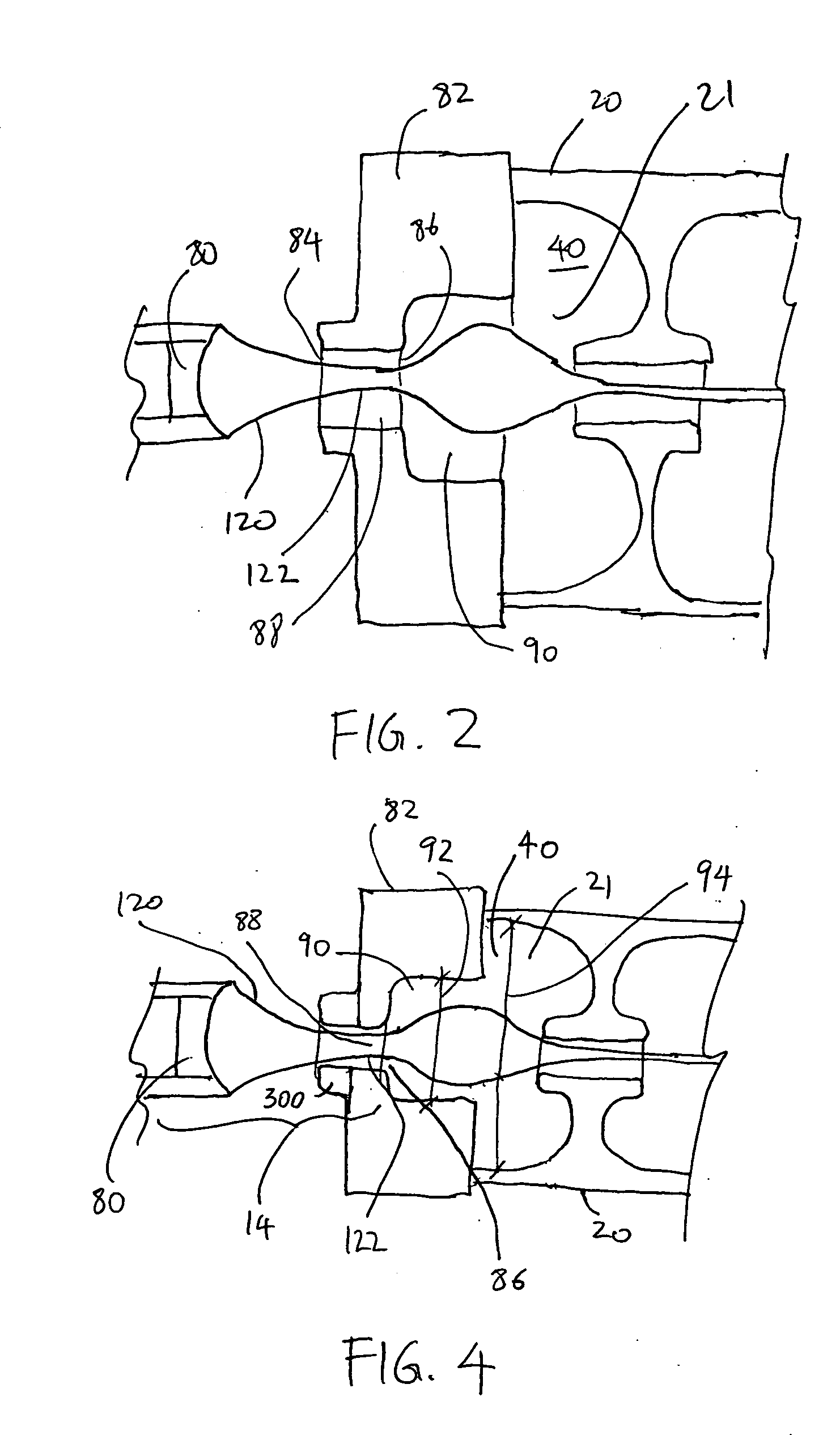

[0035] A standing wave electron beam accelerator employing (1) waist position optimization (2) asymmetric stepped structure, and (3) cell length variation along the length of the accelerator, has been built. The accelerator includes a low voltage electron source that operates at 30 keV (or less), and a microwave source. In one mode of operation, the accelerator delivers a beam of electrons having an energy level of 9 MeV±0.5 MeV with at least 30% transmission (at least 30% of the electrons generated at a proximal end of the accelerator is transmitted to a distal end). In another mode of operation, the accelerator delivers a beam of electrons having an energy level of 5 MeV±0.5 MeV. By configuring the asymmetric stepped structure to place the waist of the electron envelope at optimal position, and by configuring the electromagnetic cavities to provide desired phase focusing effect, the electrons traveling though the accelerator can be efficiently bunched without use of an external so...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com