Papermaking apparatus

a papermaking apparatus and papermaking technology, applied in the field of papermaking apparatuses, can solve the problems that the papermaking apparatus generally has little use for the tube-type board, and achieve the effects of improving paper quality, enhancing the natural harmonic pitch and improving the versatility of the papermaking apparatus

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

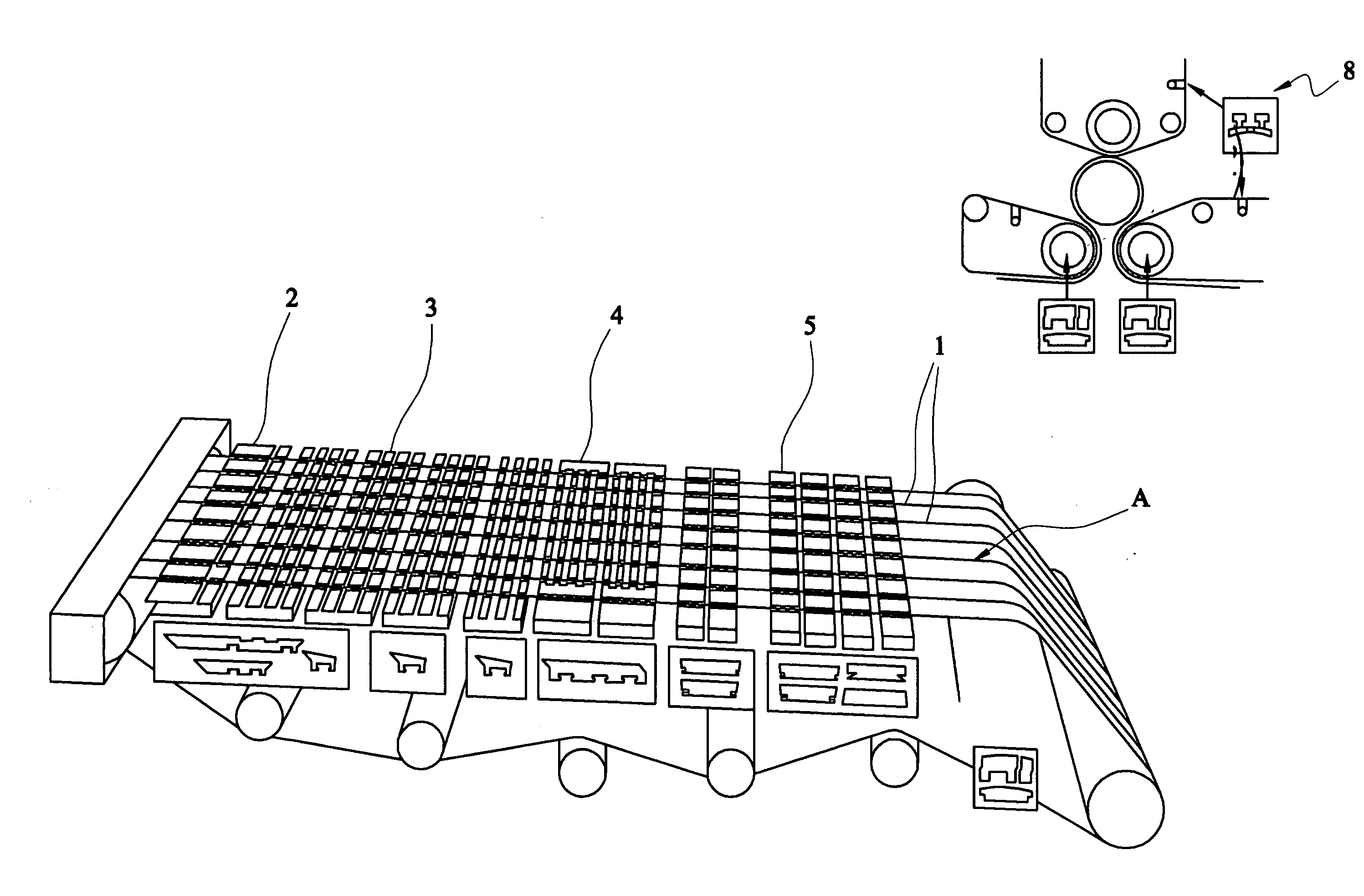

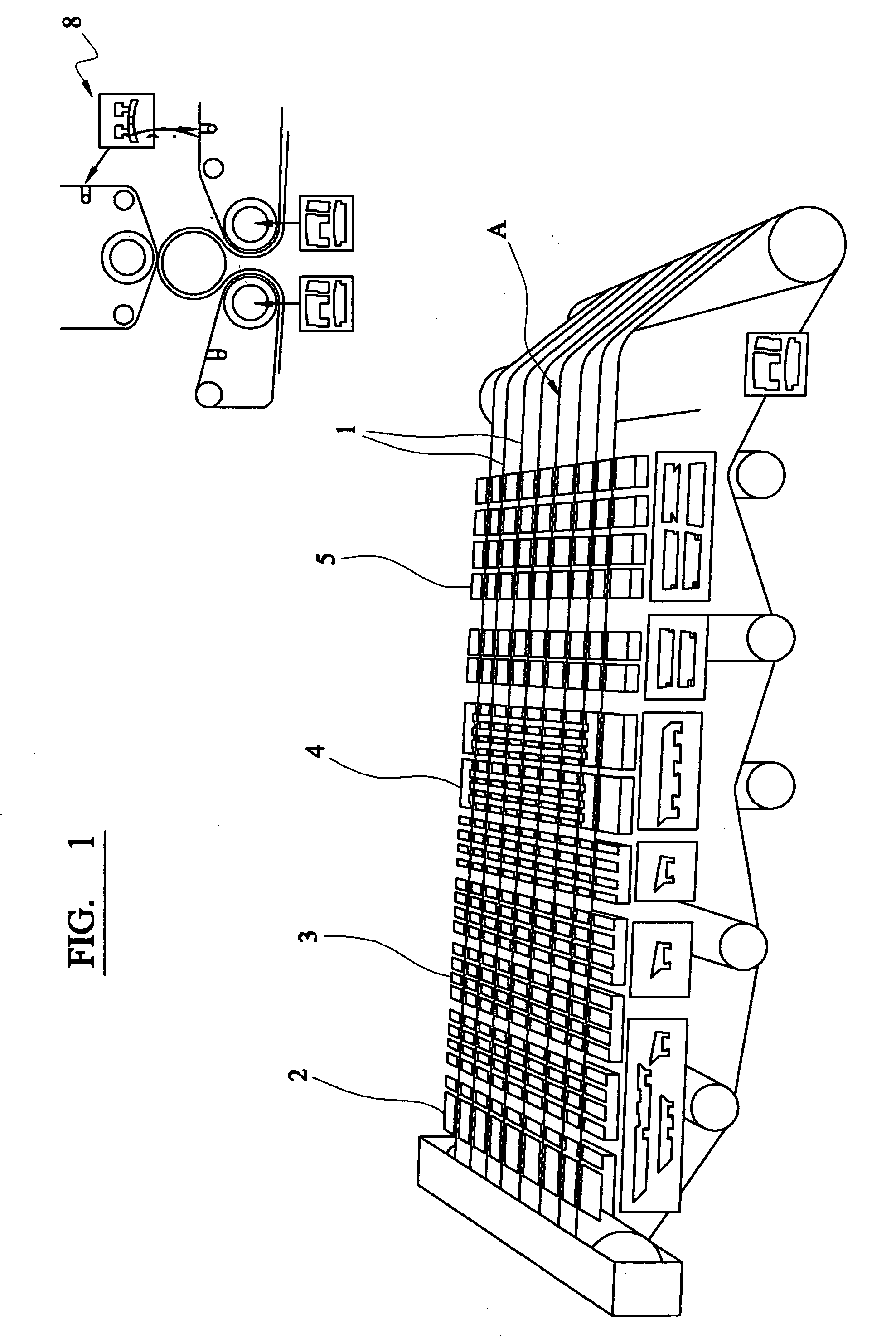

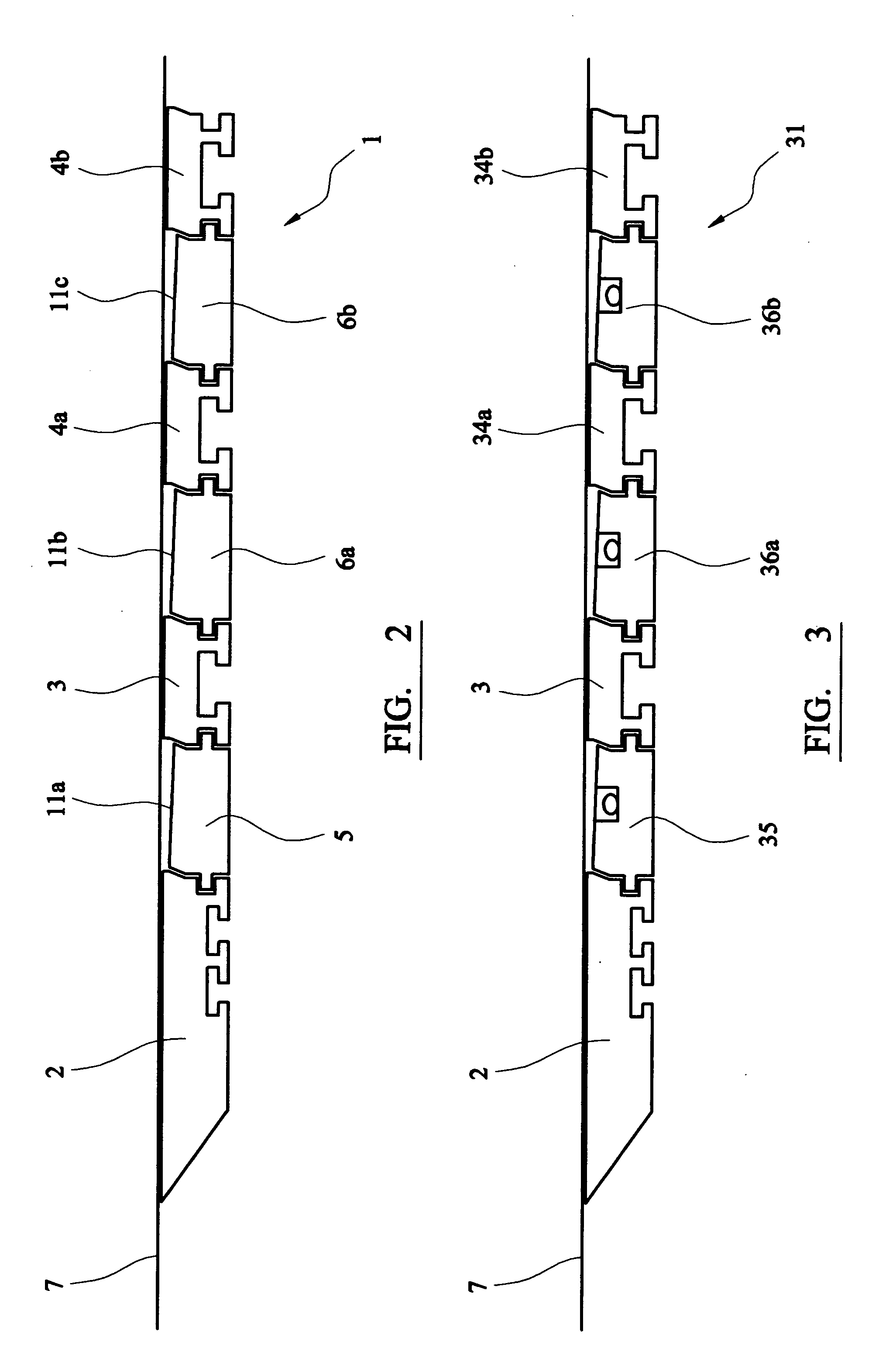

[0052]FIG. 2 illustrates schematically an isolated side view of the assembly of forming elements 1 of a first embodiment of a papermaking apparatus of the invention. The assembly of forming elements 1 includes a primary blade 2 positioned immediately after the one or more supply means (not shown), a first secondary support blade 3, first and second consecutive additional secondary support blades 4a and 4b, a first drainage deckle 5 and first and second additional drainage deckles 6a, 6b. The assembly of forming elements 1 defines a discontinuous upper surface for supporting the papermaking suspension carried by a papermaking wire 7.

[0053] The primary blade 2 is illustrated alone in FIG. 4. A trailing face 42a of the primary blade 2 tapers downwardly and forwardly. A leading face 41a of the primary blade 2 is perpendicular to the upper and lower surfaces and is provided with a shoulder 42 at its upper edge. The lower surface incorporates T-shaped slots 49a, 49b which engage T-shaped...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com