Construction component with a longitudinally changing cross-section shape

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

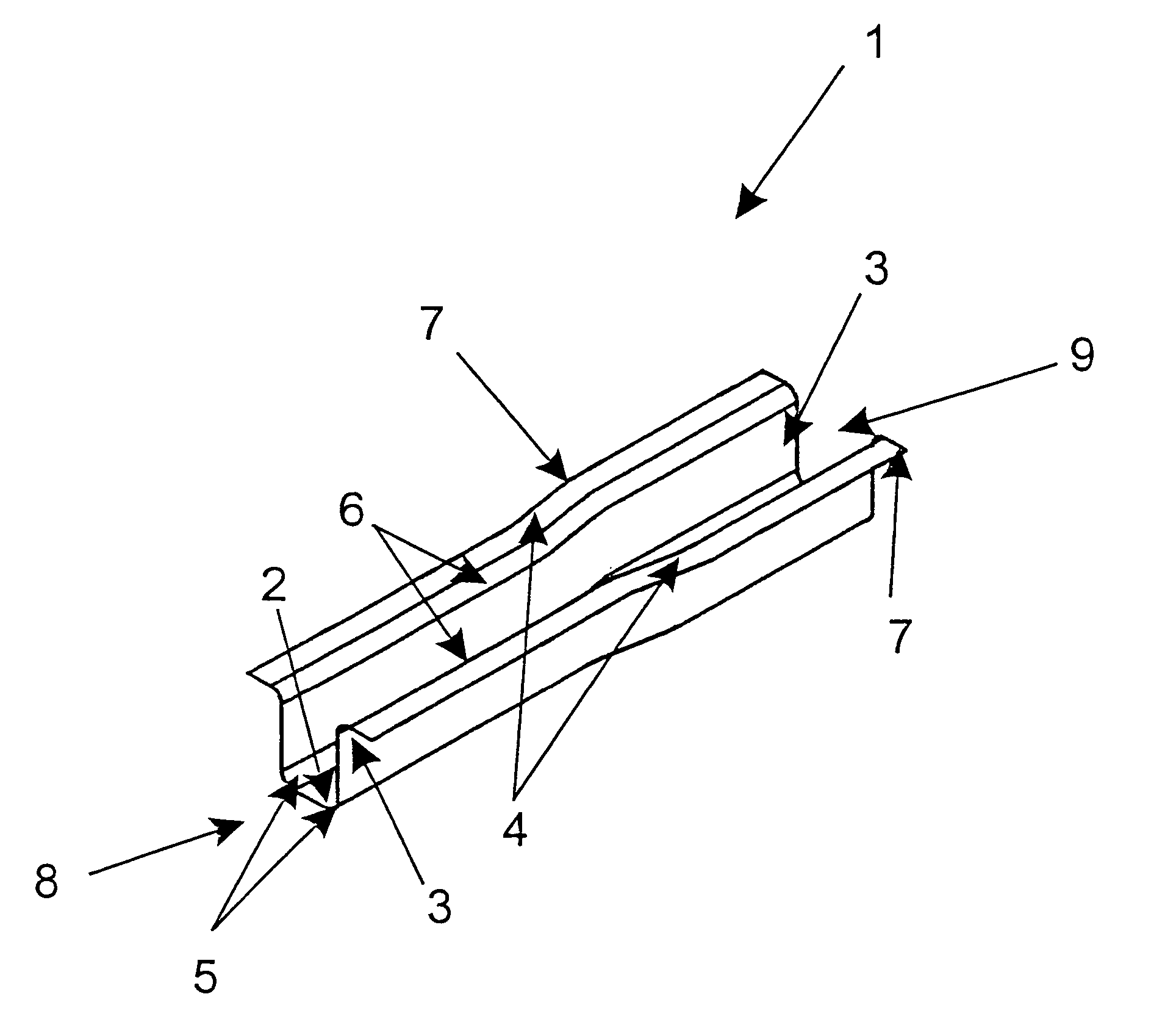

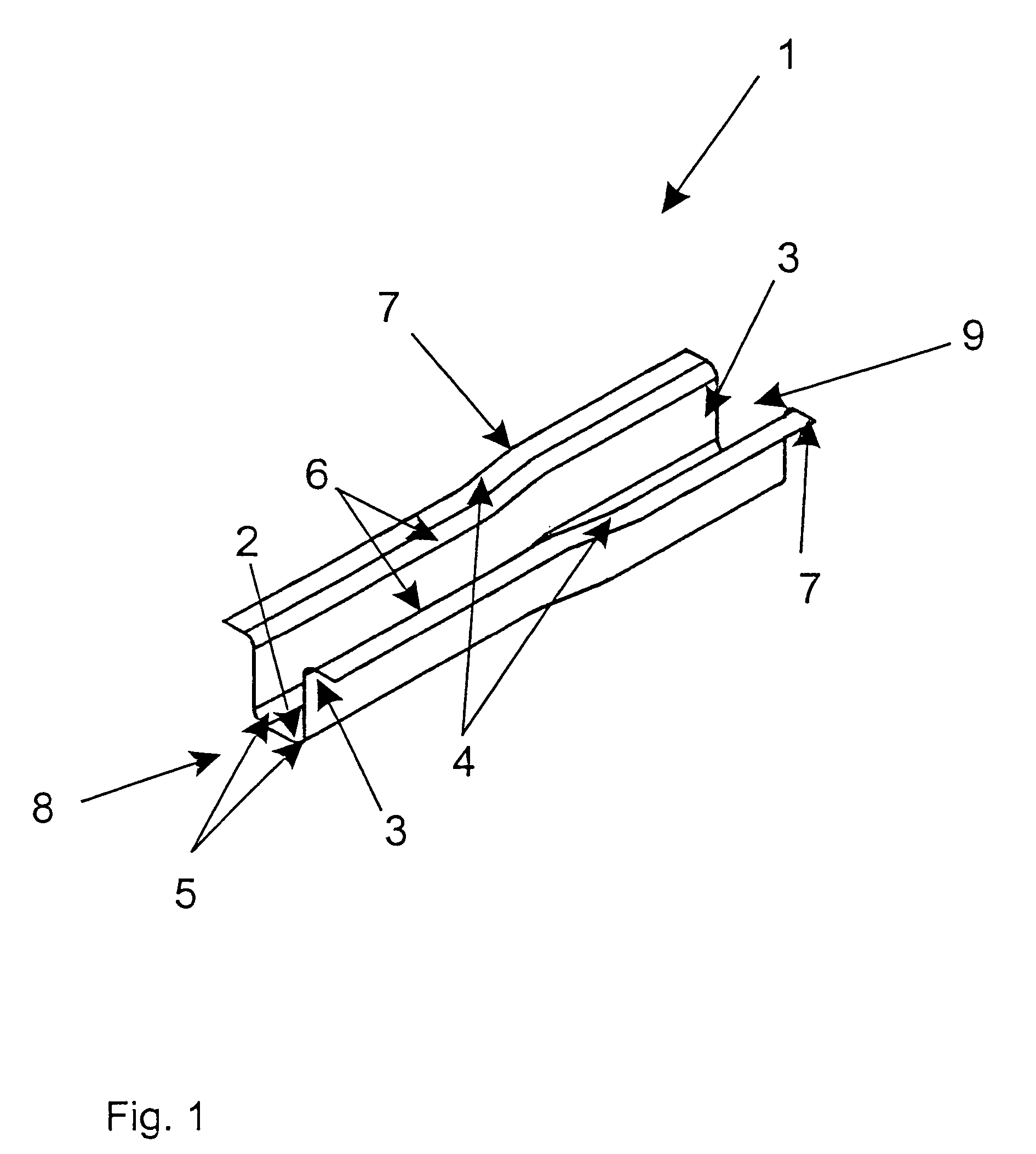

[0041]FIG. 1 shows an illustrative embodiment of an inventive construction component 1. This shape is conventionally referred to as “hat” or “omega” profile. The construction component 1 is made of TRIP-steel, which is supplied as a starting material in the form of a roll. The starting material is profiled or shaped from a planar condition into the construction component 1 in a roller profiling device. The roller profiled construction component 1 exhibits a base 2 and opposing sidewalls 3 with flanges 4. These sidewalls 3 transition to the base 2 via a bowed or curved area 5. Further, the construction component 1 exhibits oppositely lying flanges 4 respectively radiating out from the sidewalls 3, which flanges are produced by roller profiling. The sidewalls 3 transition via flange curves 6 into the flanges 4. The flanges 4 end with edges 7. The sidewalls 3 are so dimensioned, that openings can be introduced which make possible the passage through of an electrode of a welding rod or ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com