Fence post

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

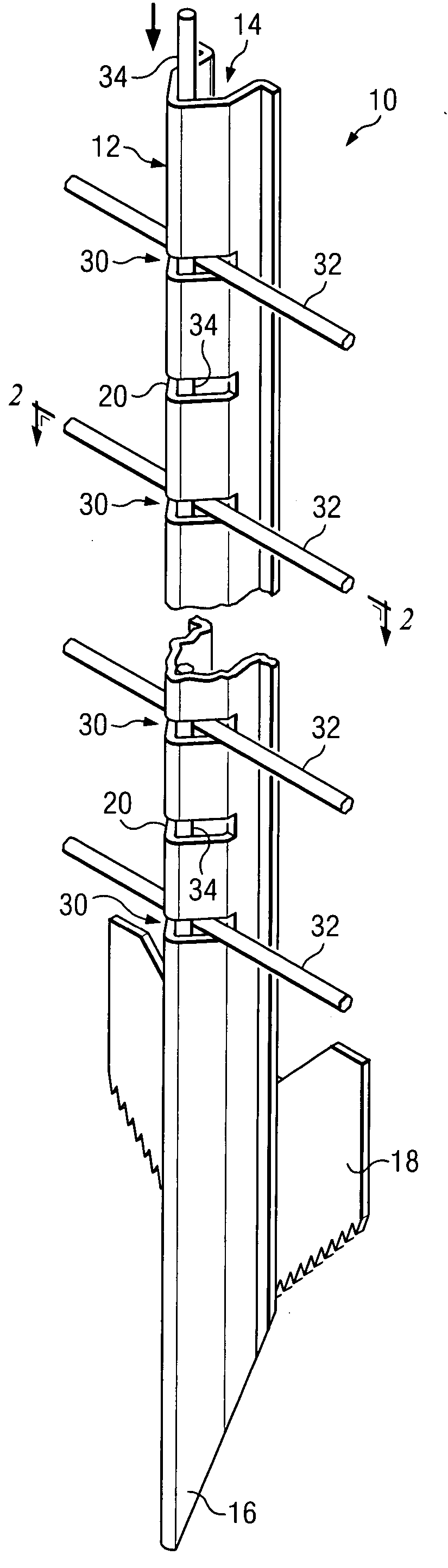

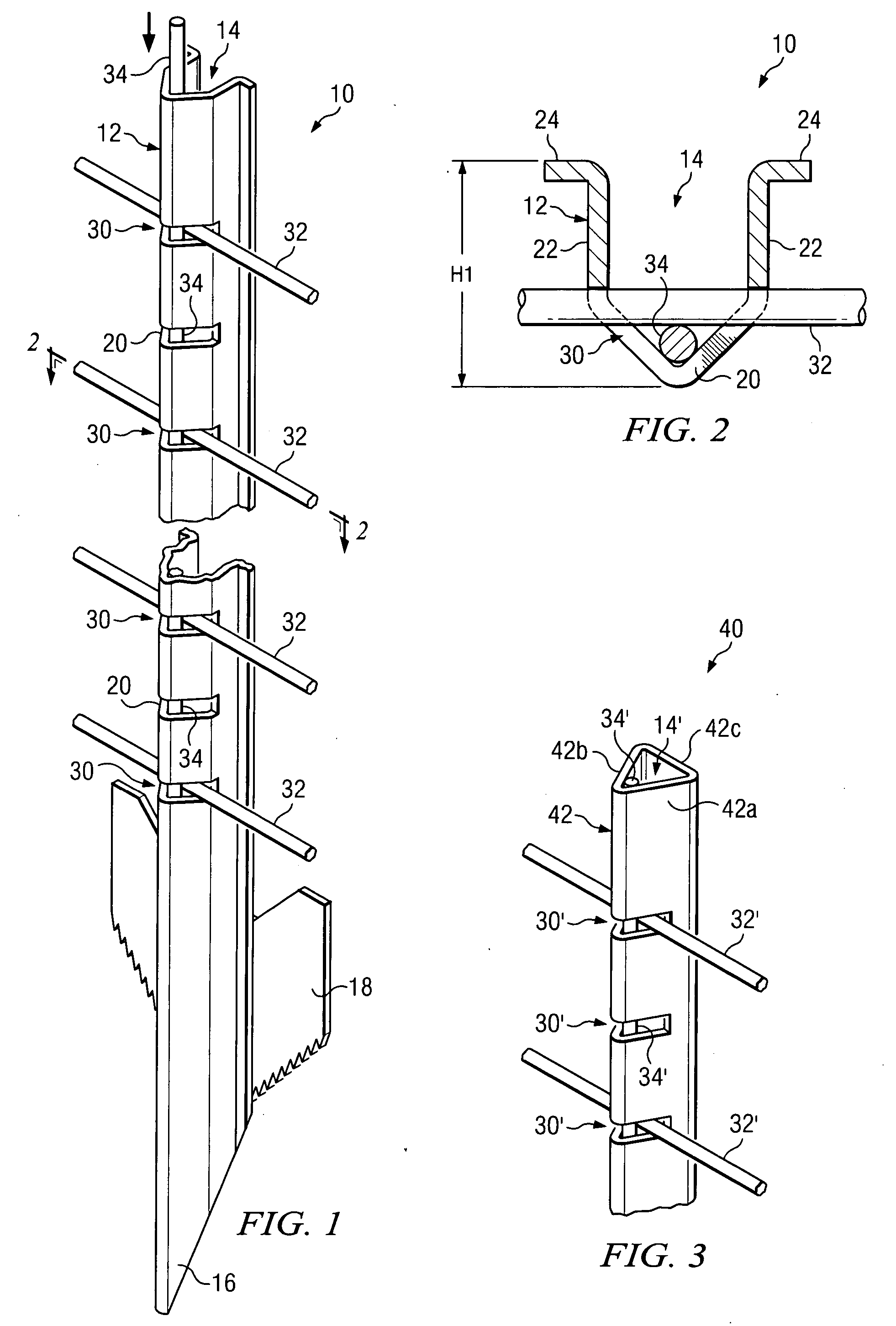

[0021] Referring now to the Drawings, and particularly to FIGS. 1 and 2 thereof, there is shown a fence post 10 comprising the invention. The fence post 10 comprises a wall 12 defining an interior 14. The wall 12 of the fence post 10 comprises a unitary construction formed from steel or any other high strength, weather resistance material, however, multiple component walls may also be used in the practice of the invention. The interior 14 defined by the wall 12 may be either open as shown in FIGS. 1 and 2, or partially closed, or fully closed depending upon the requirements of particular applications of the invention.

[0022] Referring specifically to FIG. 1, the lower end of the fence post 10 comprises a beveled point 16. The beveled point 16 facilitates insertion of the fence post 10 into the ground. As will be appreciated by those skilled in the art, other types and kinds of lower end configurations for the fence post 10 may be utilized in the practice of the invention dependent up...

second embodiment

[0029] Referring to FIG. 3 there is shown a fence post 40 comprising the invention. Many of the component parts of the fence post 40 are substantially identical in construction and function to component parts of the fence post 10 illustrated in FIGS. 1 and 2 and described hereinabove in conjunction therewith. Such identical component parts are designated in FIG. 3 with the same reference numerals utilized above in the description of the fence post 10, but are differentiated therefrom by means of a prime (′) designation.

[0030] The fence post 40 comprises a triangularly shaped wall 42. The wall 42 comprises three interconnected panels 42a, 42b and 42c. As will be appreciated by those skilled in the art, when the wall 42c is utilized the interior 14′ of the fence post 40 is completely enclosed. However, the wall 42c may be dispensed with entirely in which case the interior 14′ of the fence post 40 is open. The wall 42c can also comprise inwardly turned flanges in which case the interio...

third embodiment

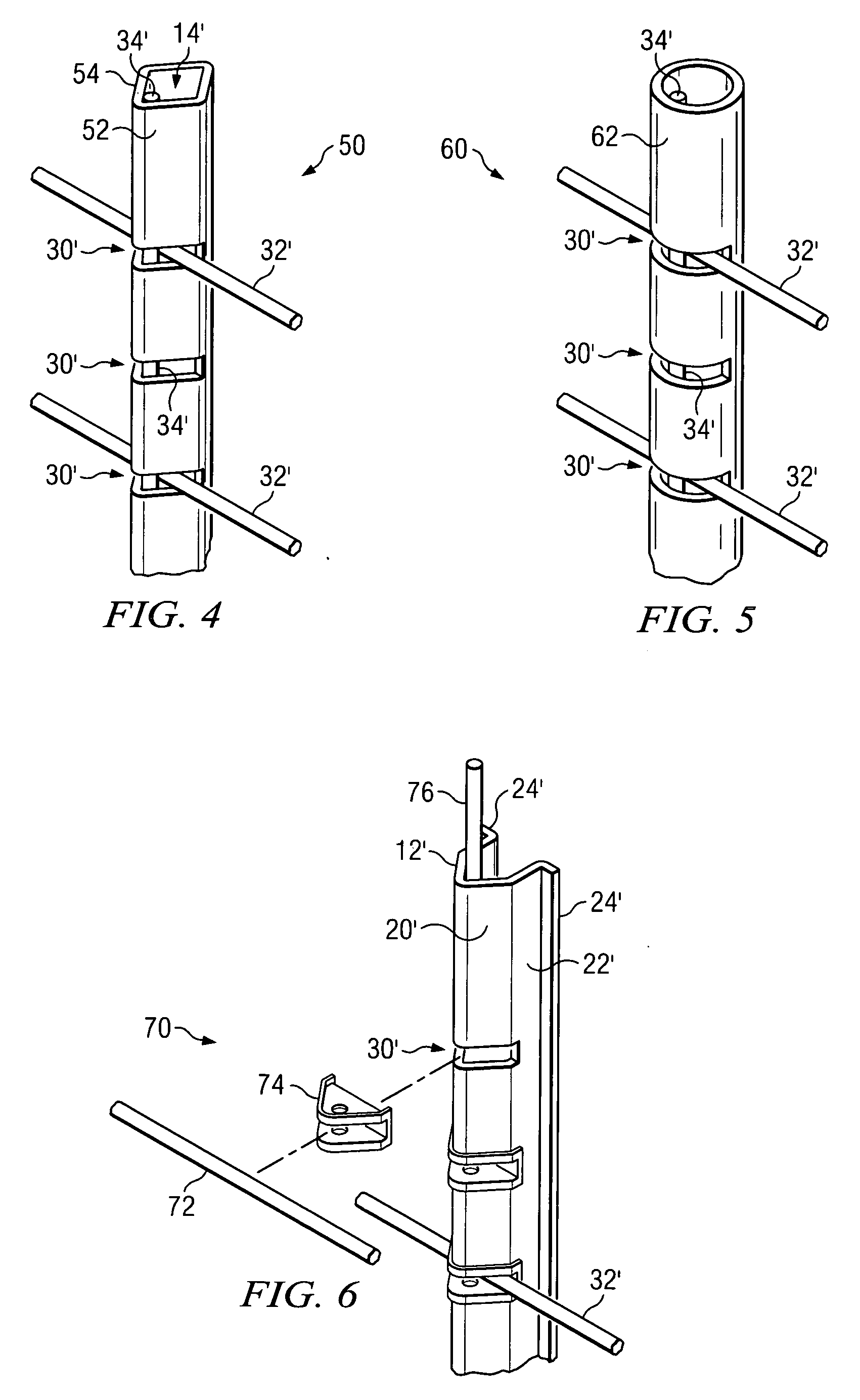

[0031] Referring to FIG. 4 there is shown a fence post 50 comprising the invention. The fence post 50 includes numerous component parts which are substantially identical in construction and function to component parts of the fence post 10 illustrated in FIGS. 1 and 2 and described hereinabove in conjunction therewith. Such identical component parts are designated in FIG. 4 with the same reference numerals utilized in the description of the fence post 10 but are differentiated therefrom by means of a prime (′) designation.

[0032] The fence post 50 differs from the fence post 10 of FIGS. 1 and 2 in that the fence post 50 comprises a wall 52 which is square or rectangular in configuration. The horizontally disposed slots 30′ extend into the wall 52 through one corner 54 thereof thereby extending into the interior 14′ of the fence post 50.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com