One-piece soft spout valve assembly for a no-spill drinking cup

a drinking cup and valve assembly technology, applied in the field of drinking containers, can solve the problems of increased material and manufacturing costs of the valve, difficult cleaning, and prone to leakage of perforations, and achieve the effect of virtually eliminating any leakage through the valve and the lid, and relatively simple cleaning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

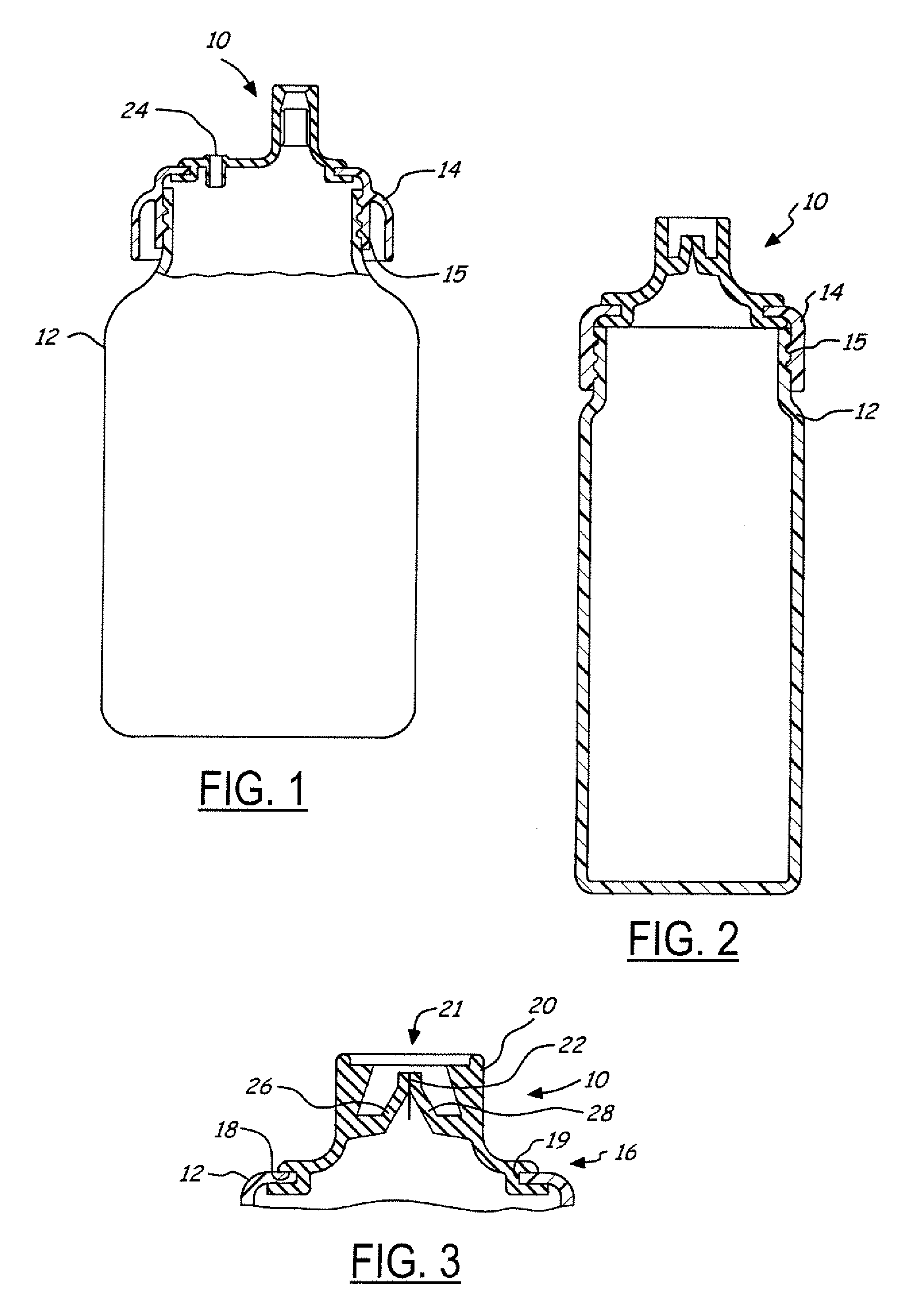

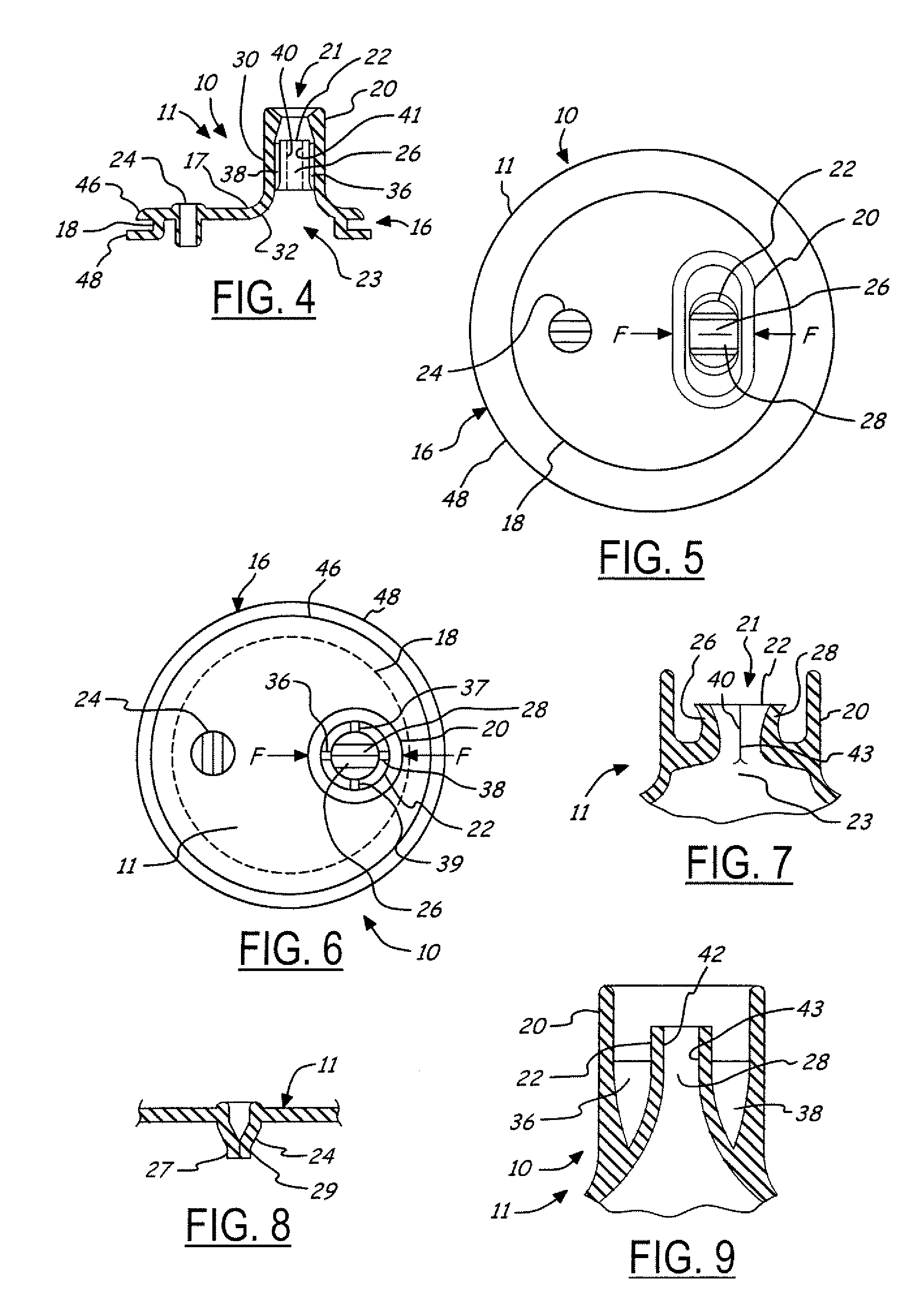

[0026] In the following figures, the same reference numerals are used to identify the same components in the various views and alternate embodiments.

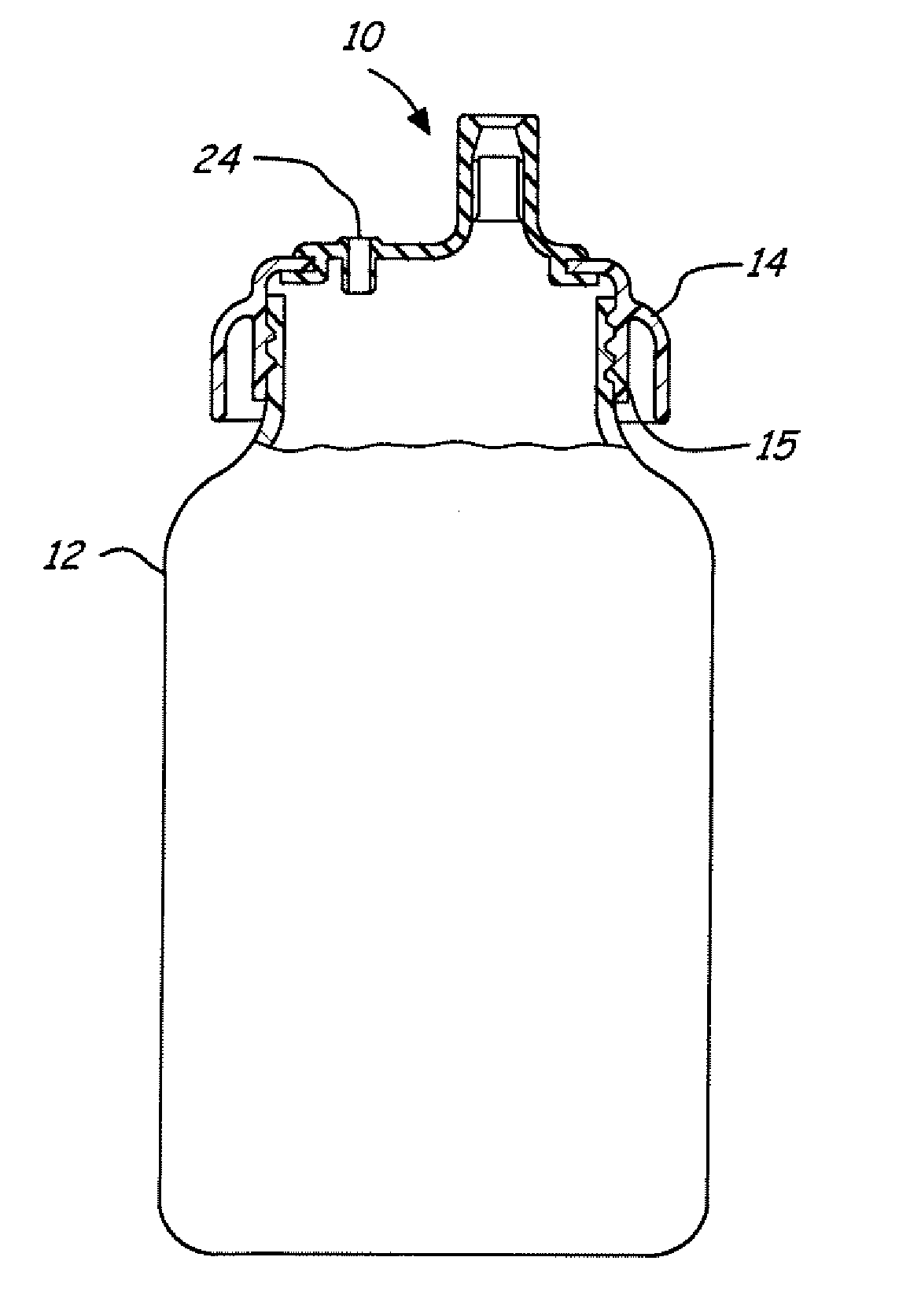

[0027] Referring now to FIG. 1, there is generally illustrated a cross-sectional view of an integral valve and spout assembly 10 attached to a drinking cup 12 according to one embodiment of the present invention. In this embodiment, the valve and spout assembly 10 is attached to a lid portion 14, which engages the drinking cup 12 by threads 15. Alternatively, as would be recognized by one of ordinary skill in the art, the valve and spout assembly 10 can be directly attached to the drinking cup without the need for a lid portion. Also one of ordinary skill in the art would recognize that lid portion may also be attached to the drinking cup in a variety of other suitable ways.

[0028] The valve and spout assembly 10 preferably is comprised of a flexible material, such as silicone. Alternatively, a variety of other suitable materials may b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com