Systems, dispensers and methods for laundry additives

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

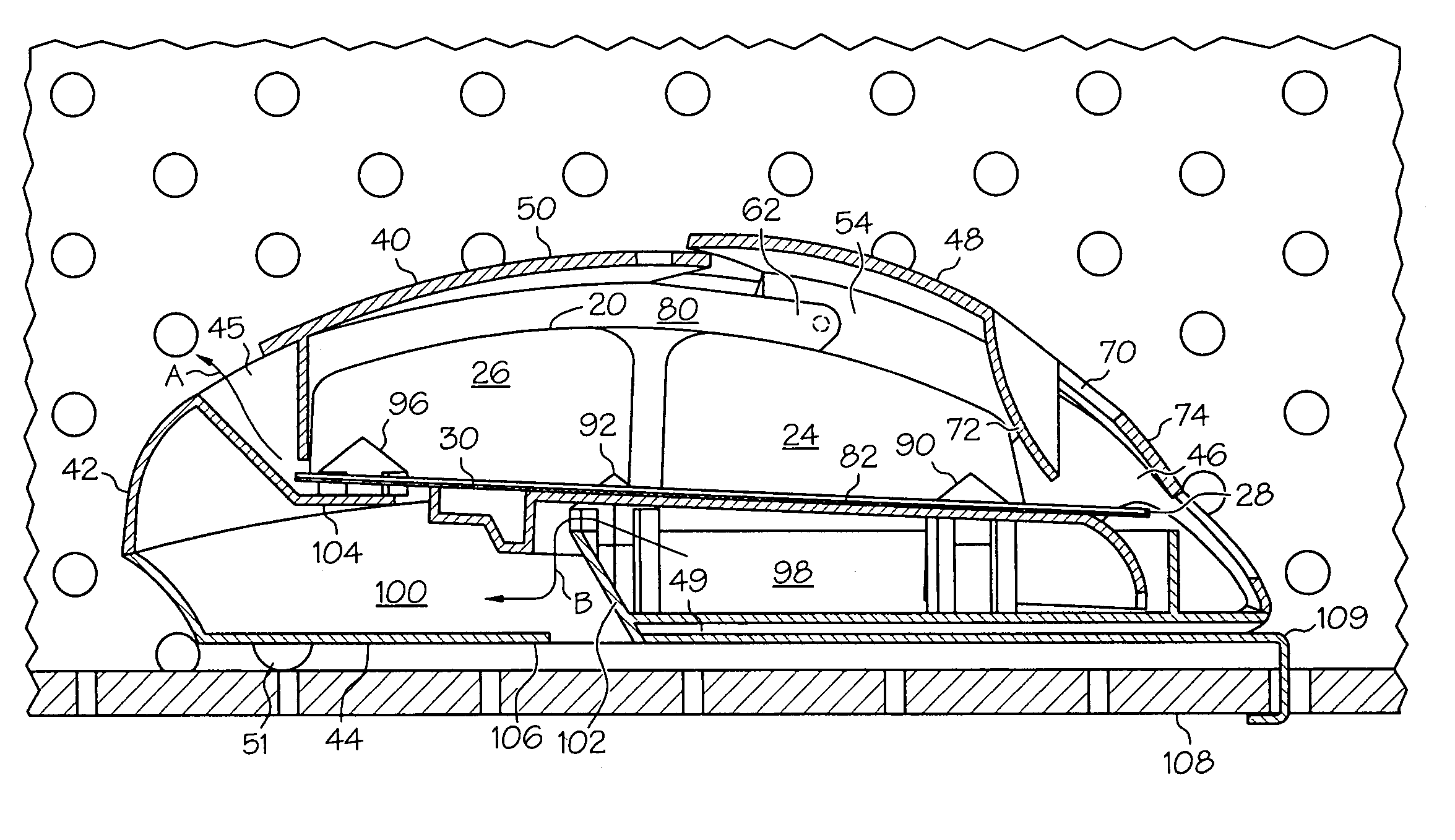

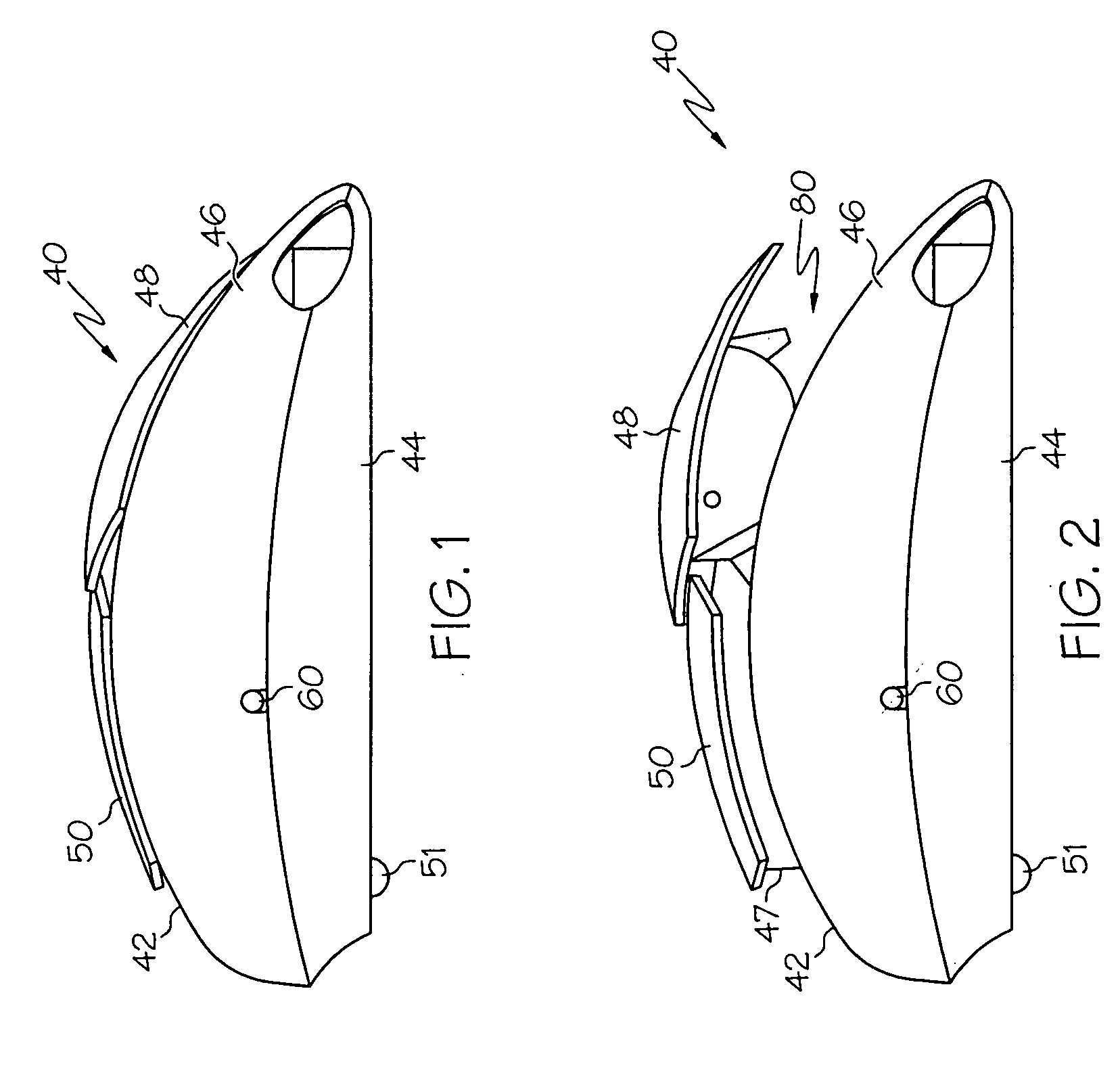

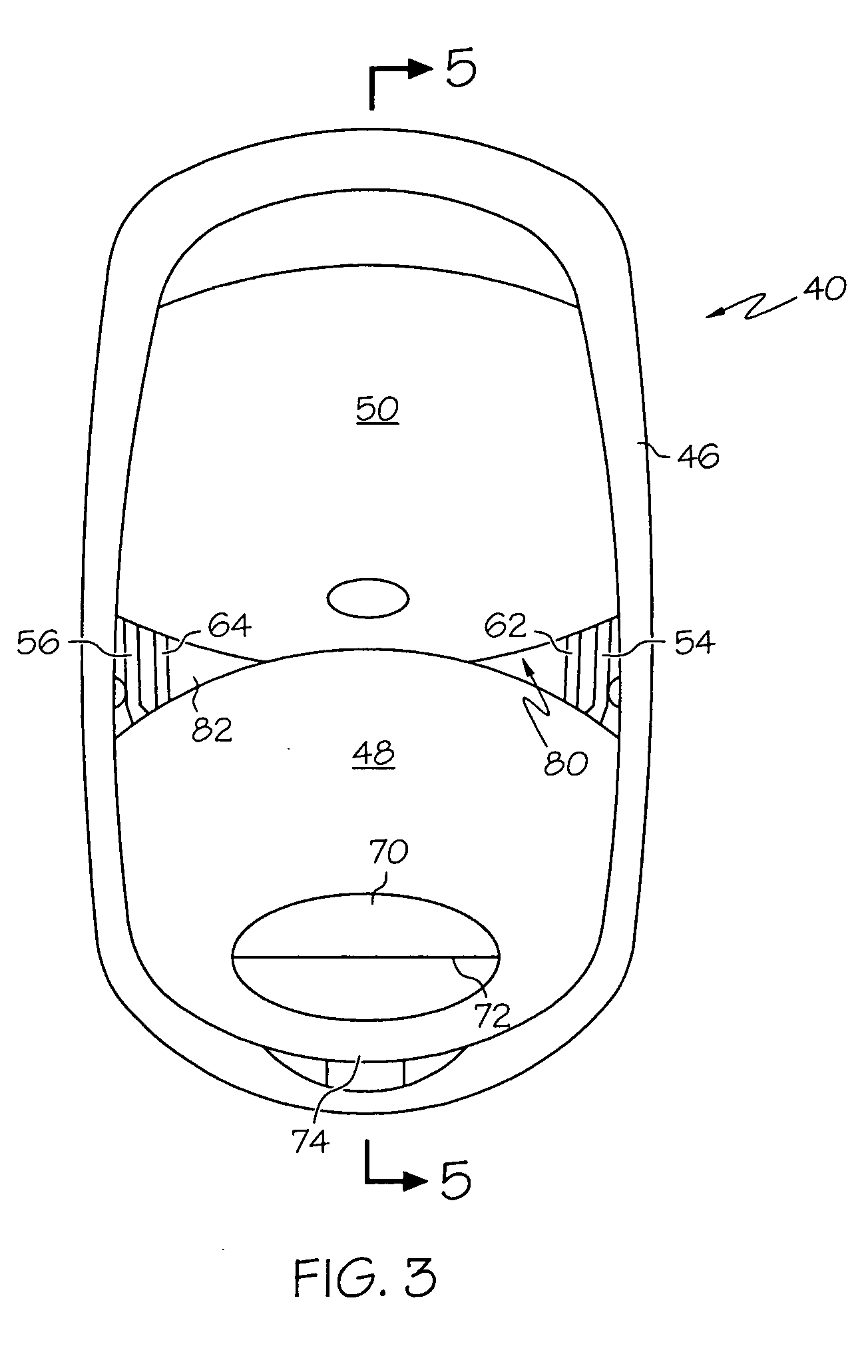

[0035] The systems, dispensers and methods of the present invention are intended to provide dispensing of laundry additive materials into different stages of the laundering process from a single unit dose package which contains such additives. Such additive materials are dispensed into the washing machine as the machine proceeds through its operational wash and rinse cycles. This is accomplished using a dispenser having a substantially rigid housing structure which is positioned within the machine and which holds and opens a unit dose package containing the additive materials to be dispensed.

[0036] Dispensing of laundry additive materials in accordance with this invention takes place in a conventional automatic washing machine useful for the laundering of fabrics. Such automatic washing machines are those typically found in the home or in businesses such as self-service laundromats wherein individual consumers can launder their own loads of fabrics.

[0037] Automatic washing machine...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com