Container fitment having ellipsoidal opening

a technology of container and opening, applied in the field of fittings, can solve the problems of splattering of contents, rushing of air into the container, and concomitant dramatic fluctuation in the rate of outflow of container contents, and achieves the effect of enhancing the uniformity of tearing away of the membrane and minimizing the force required for initiation of the tearing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

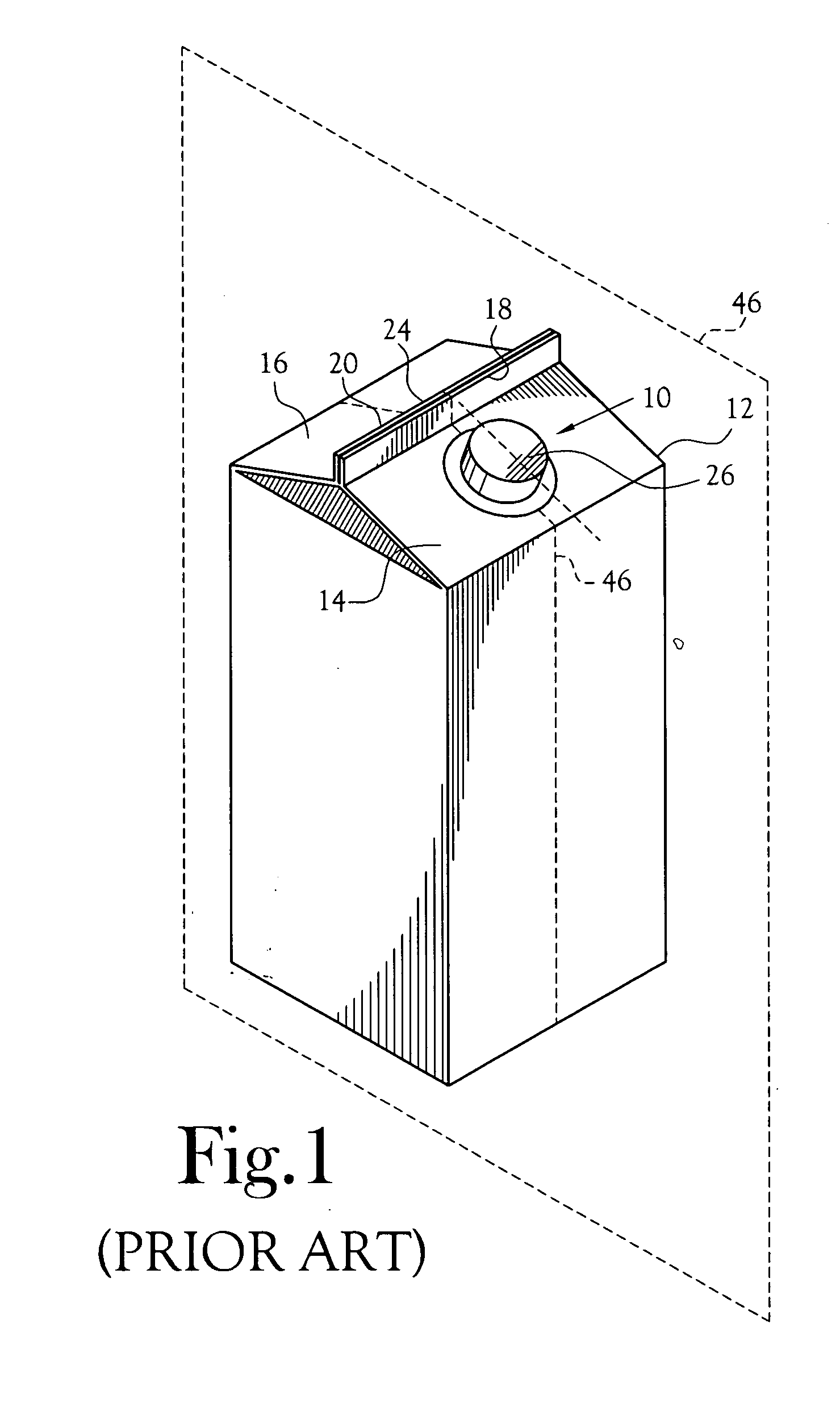

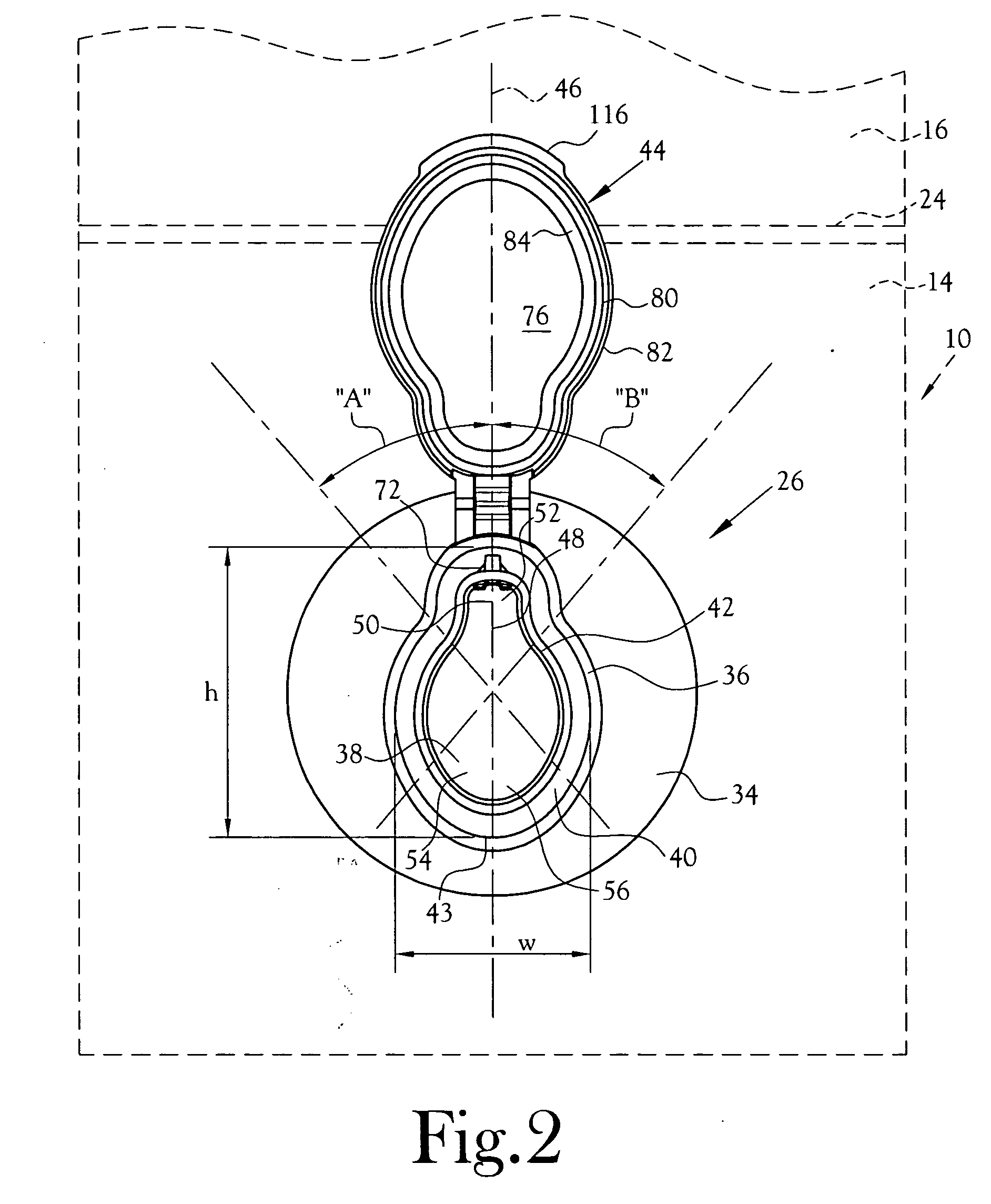

[0033]FIG. 1 depicts a prior art gable top type paperboard container 10. The top end 12 of the container is closed as by multiple panels folded inwardly of the center of the container to define first and second lateral inclined panels 14 and 16 (among others) having their distal edges 18 and 20 bonded together to define a fin 24. The depicted container includes an opening 58 (See FIG. 7) through the thickness of the top panel 14 and a fitment 26 affixed to the panel in overlying and covering relationship to the opening, thereby providing a means for the dispensing of the contents of the container out through the fitment. Other containers having pour spouts affixed to the top end of a side wall of the container have been proposed. Further, the prior art includes containers having pour spouts associated with a flat top end of the container. The present fitment is also useful in these and other containers.

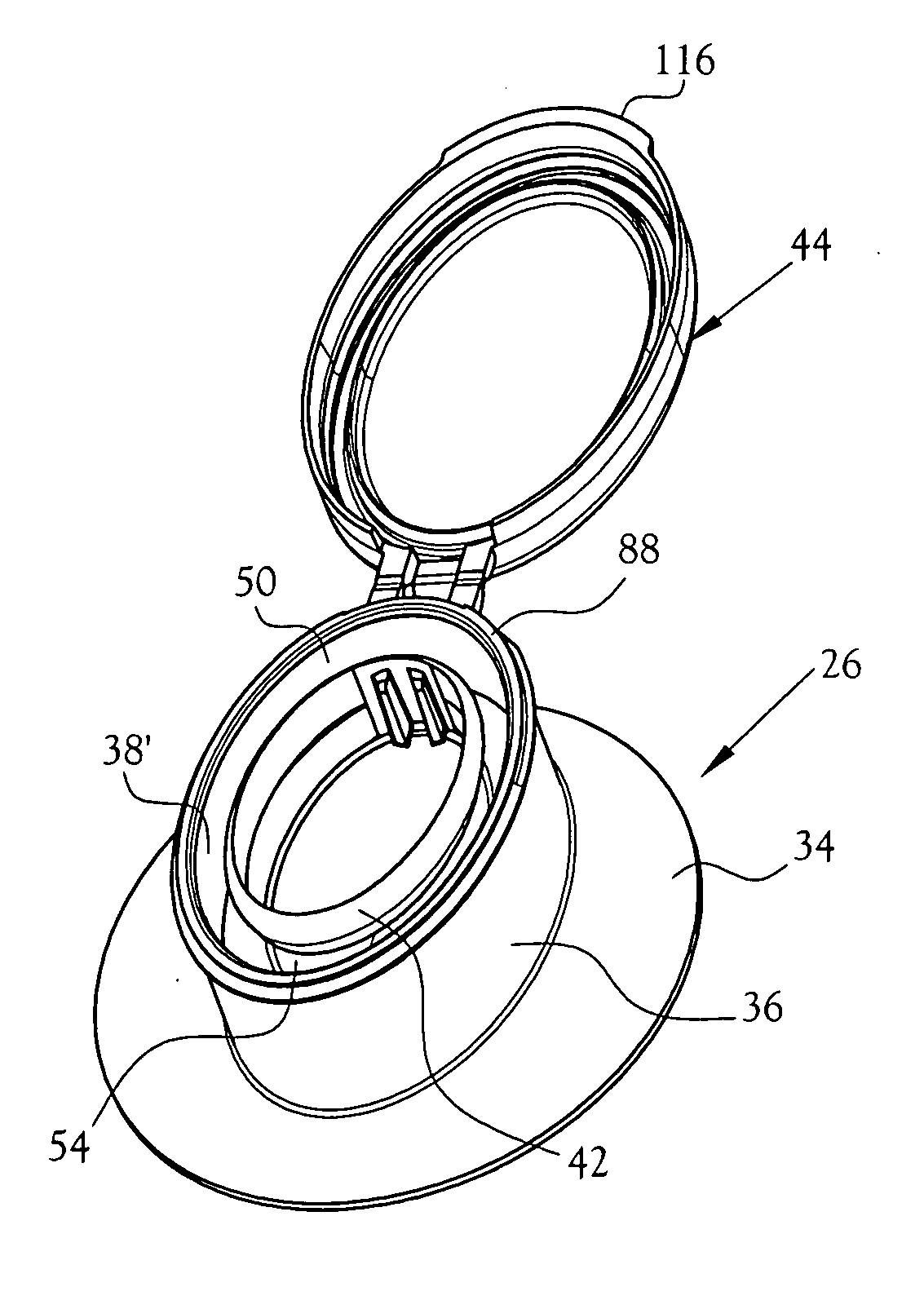

[0034]FIG. 2 depicts one embodiment of a fitment 26 embodying various of the fea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com