Payload fairing separation system

a technology for separation systems and payload fairings, which is applied in the direction of transportation and packaging, cosmonautic vehicles, aircrafts, etc., can solve the problems of significant force insertion by the mechanism on the interlock, and achieve the effects of convenient transportation, improved reliability, and less expensive work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

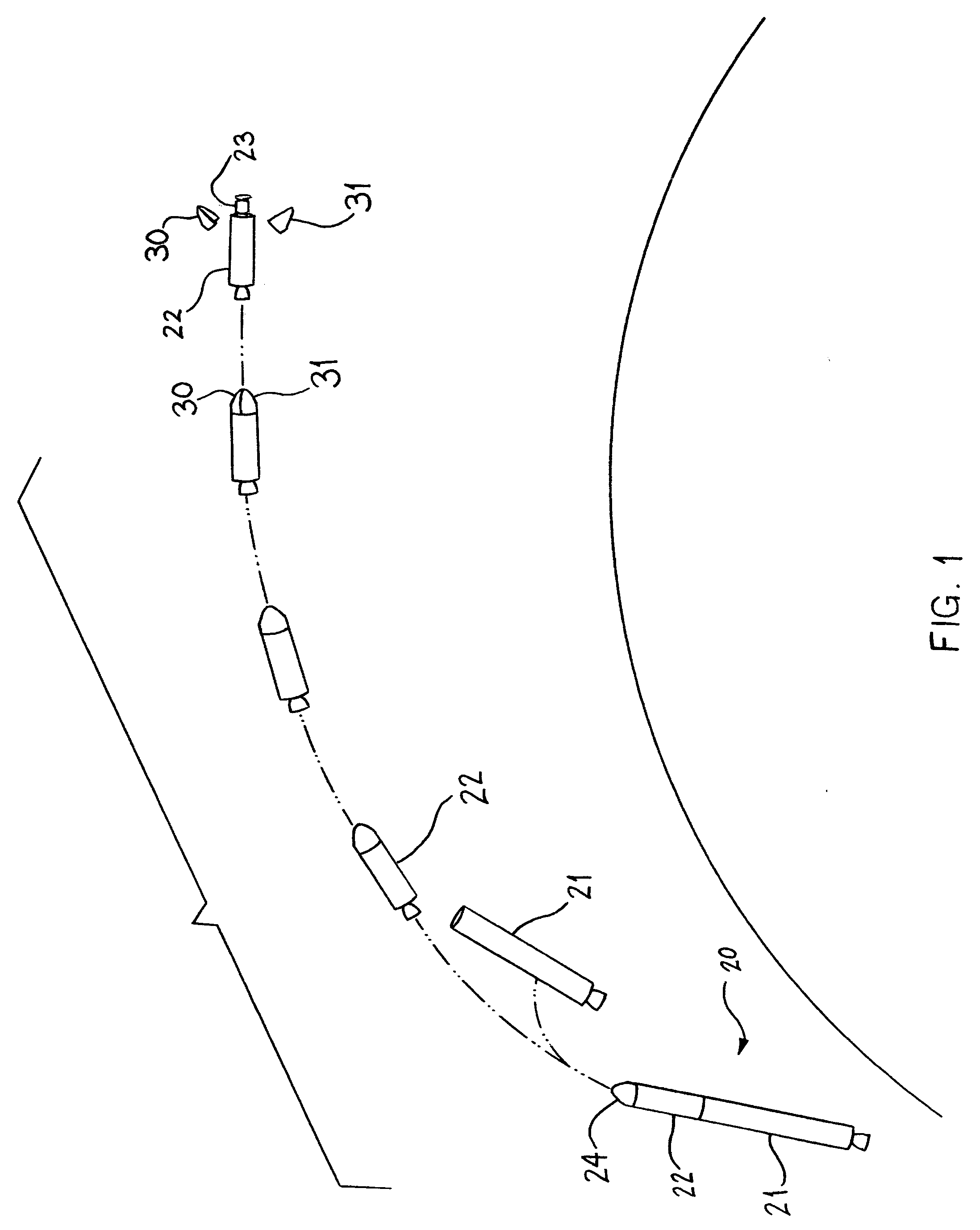

[0042] Referring to FIGS. 1-2, the typical launch vehicle, generally indicated by numeral 20, includes a lower stage 21 and upper stage 22 upon which is mounted a payload 23 covered by a fairing assembly 24. The fairing assembly 24 is generally cone shaped having a base portion 25 and a nose end 26. Typically two or more stages are necessary to place a satellite in orbit.

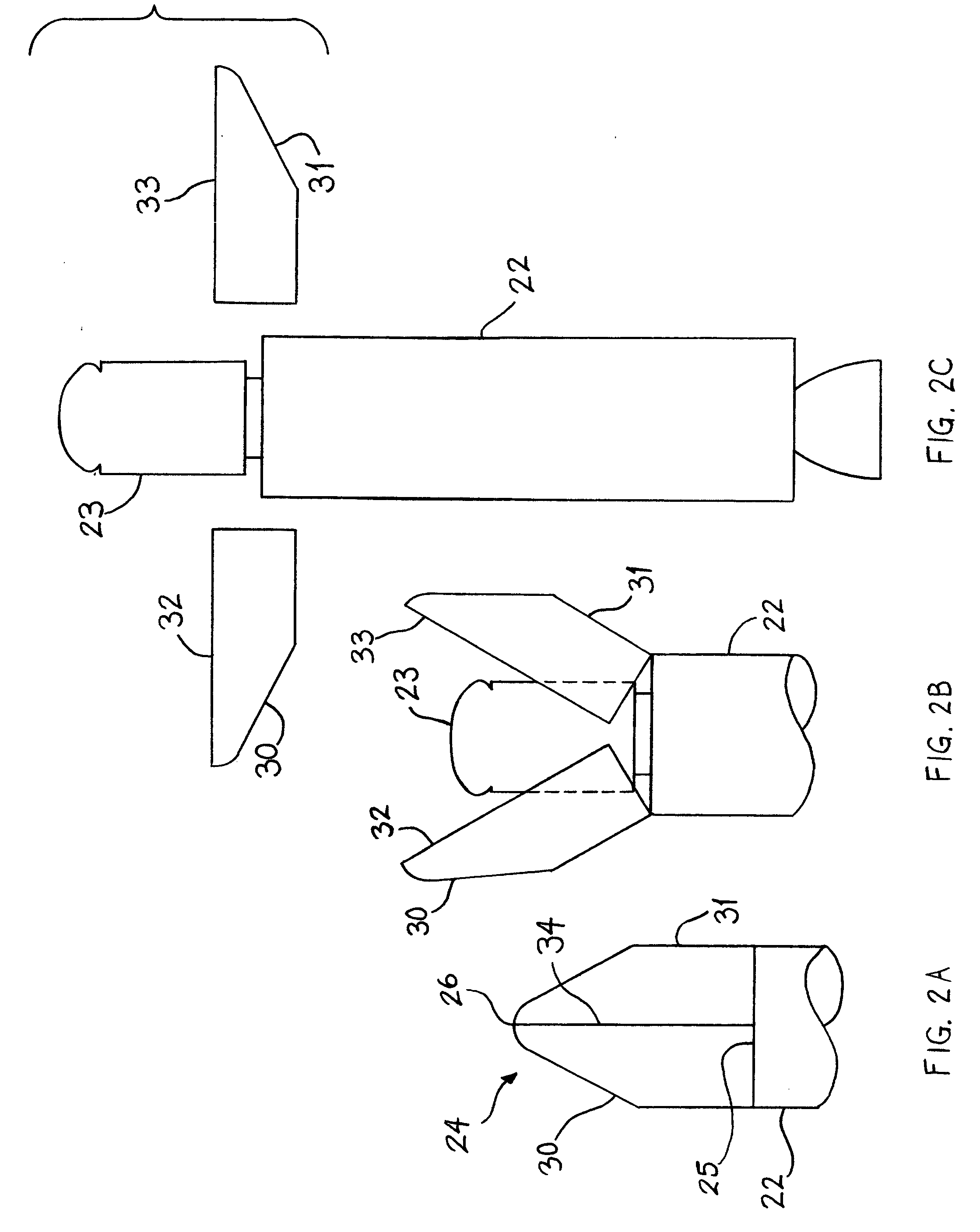

[0043] Referring to FIG. 2A to 2C, the fairing comprises two fairing halves 30 and 31 having mating edges 32 and 33 that meet to form a seam 34.

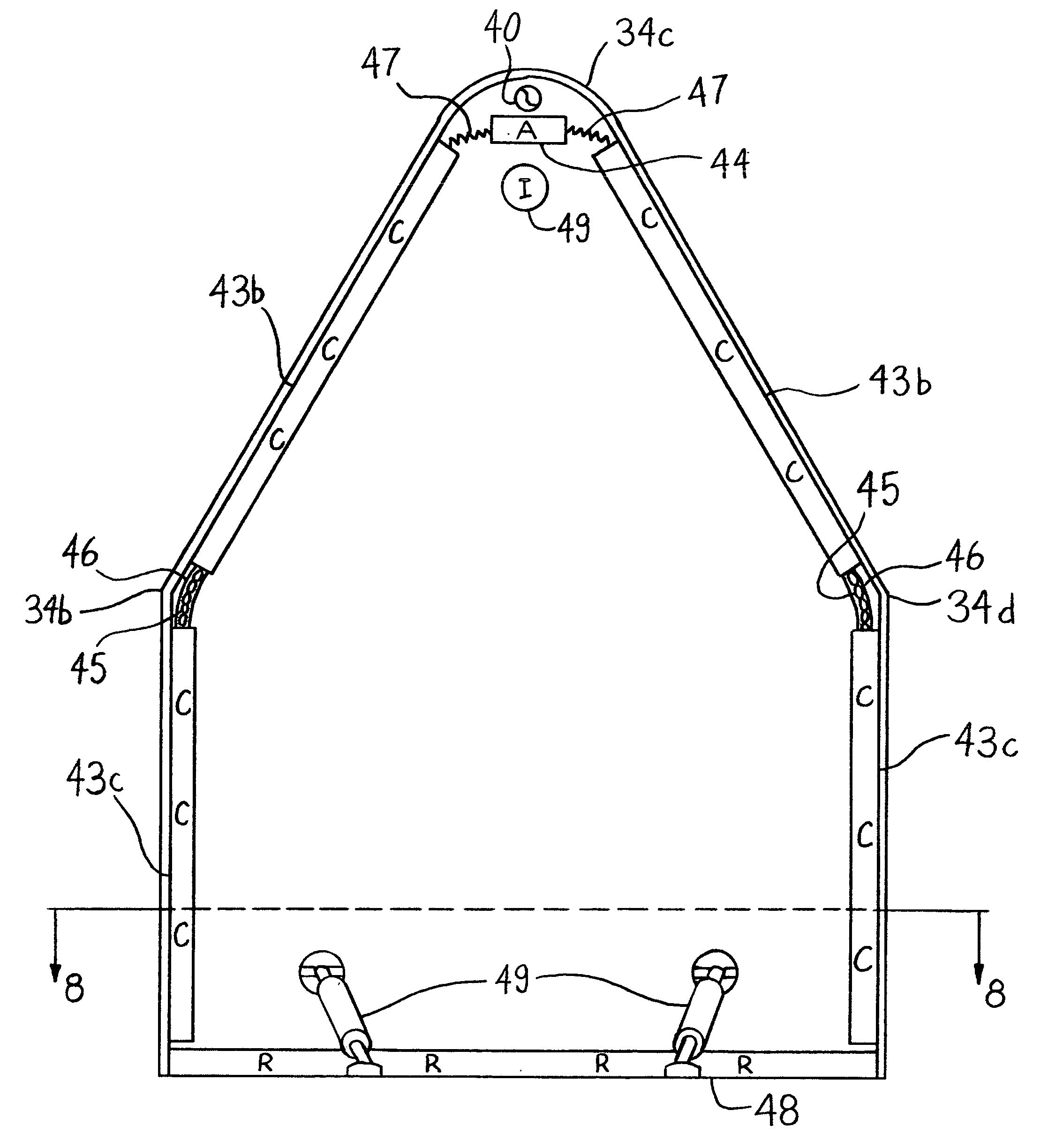

[0044] Referring to FIG. 3, at the nose 26 the mating edges of the fairing halves 30 and 31 are articulated so as to be joinable by a releasable point connector 40, represented in FIGS. 3 and 6A to 7C by a circle inscribed with an S-curve. The releasable point connector 40 also may take a variety of forms, including the Starsys FASSN. Mounted on the interior surfaces 41 and 42 of the fairing halves 30 and 31 are a plurality of resettable, releasable seam connectors 43, eac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com