Gunstock

a gunstock and spherical technology, applied in the field of gunstocks, can solve the problems of distributing a sharper and concentrated kick, and achieve the effects of reducing the risk of damage, and improving the quality of the gunstock

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

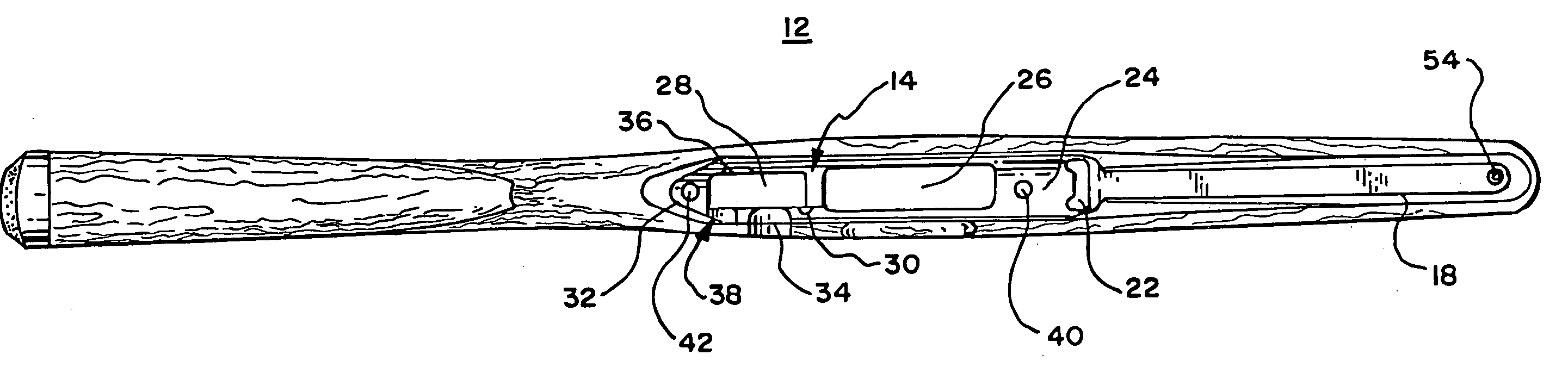

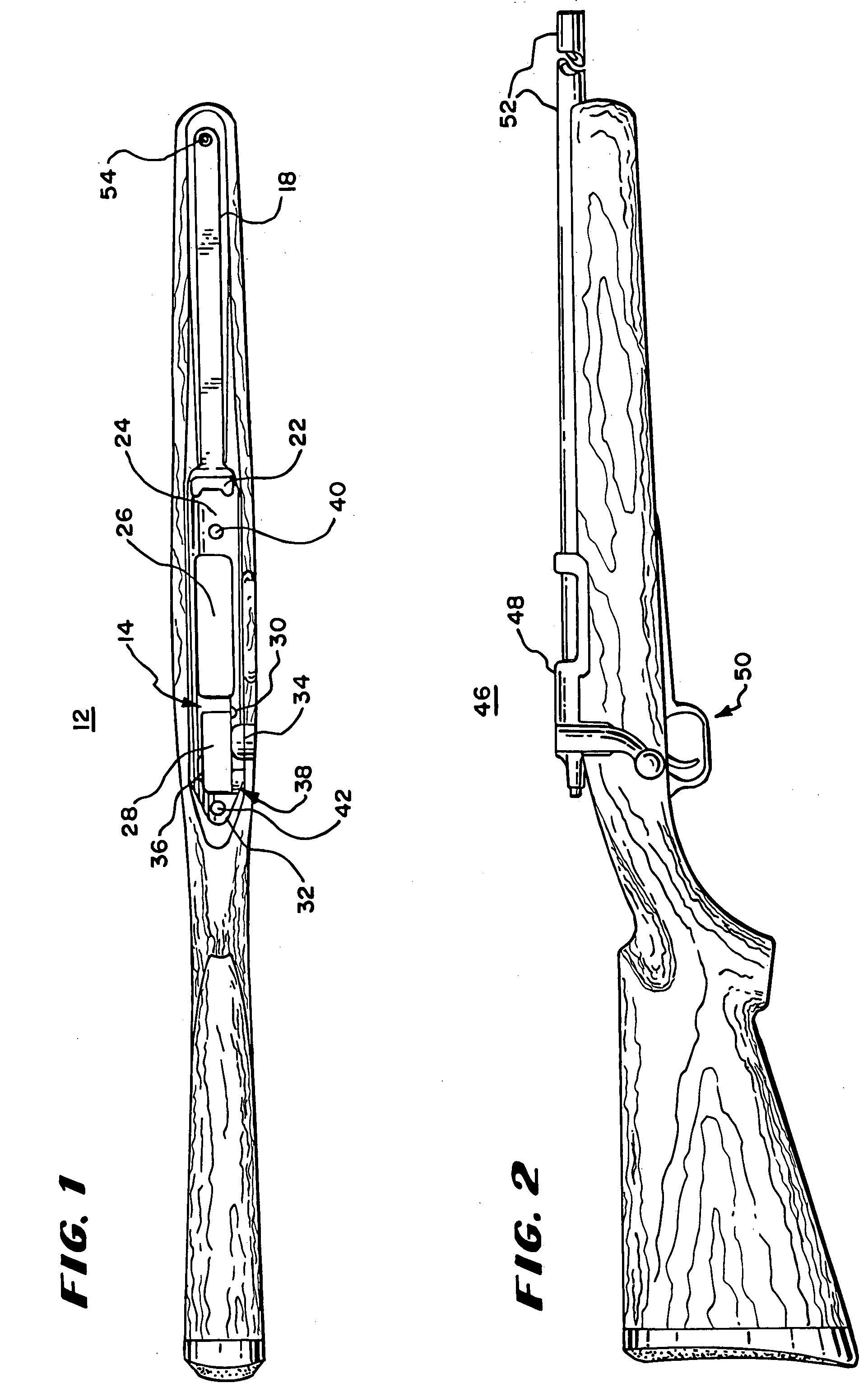

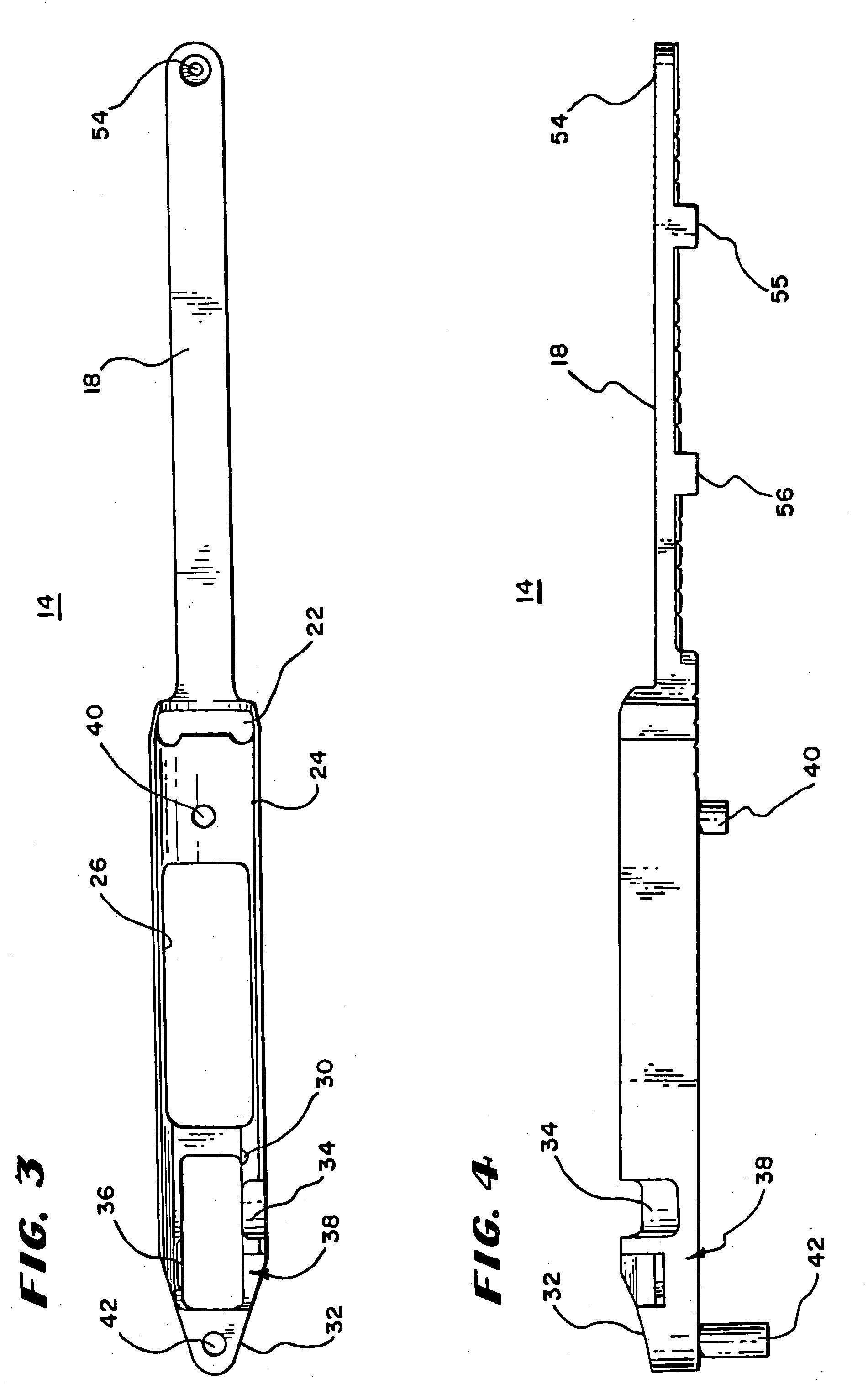

[0037] In FIG. 1, there is shown a plan view of a rifle stock 12 having a holder 14 mounted within a recess 16 within the stock 12. In the embodiment of FIG. 1, the firearm stock 12 is a wood stock or bamboo stock and the holder 14 is an aluminum holder. However, other materials can be used. Generally, the holder 14 will have a modulus of elasticity greater than three million psi and in the preferred embodiment, it is approximately nine million psi (pounds per square inch). It is mounted to have a large area of at least twelve square inches and the surface area of contact should be at least ten percent of the surface area of the support itself. The amount of surface area will of course depend upon the particular weapon but it is desirable to maximize the surface to spread the force of recoil throughout the high modulus of elasticity holder and transfer it to the wood stock or bamboo stock over the widest possible area to avoid concentrated forces on the wood stock or bamboo stock.

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com