Sill panel for a motor vehicle

a technology for motor vehicles and sill panels, which is applied in the direction of superstructures, building roofs, building components, etc., can solve the problems of annoying noise, visual disturbance, and inability to disassemble the sill panels without damage or destruction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

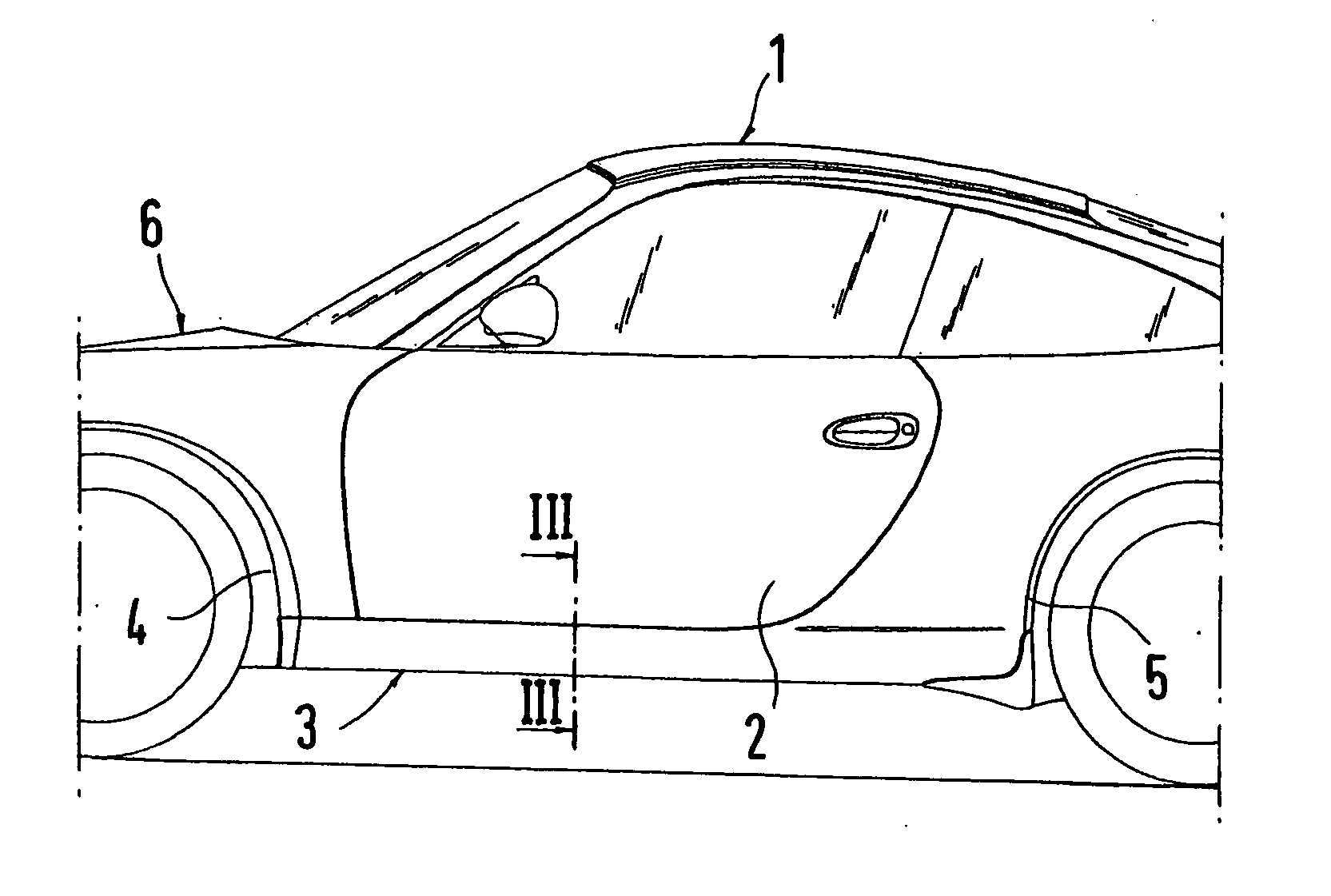

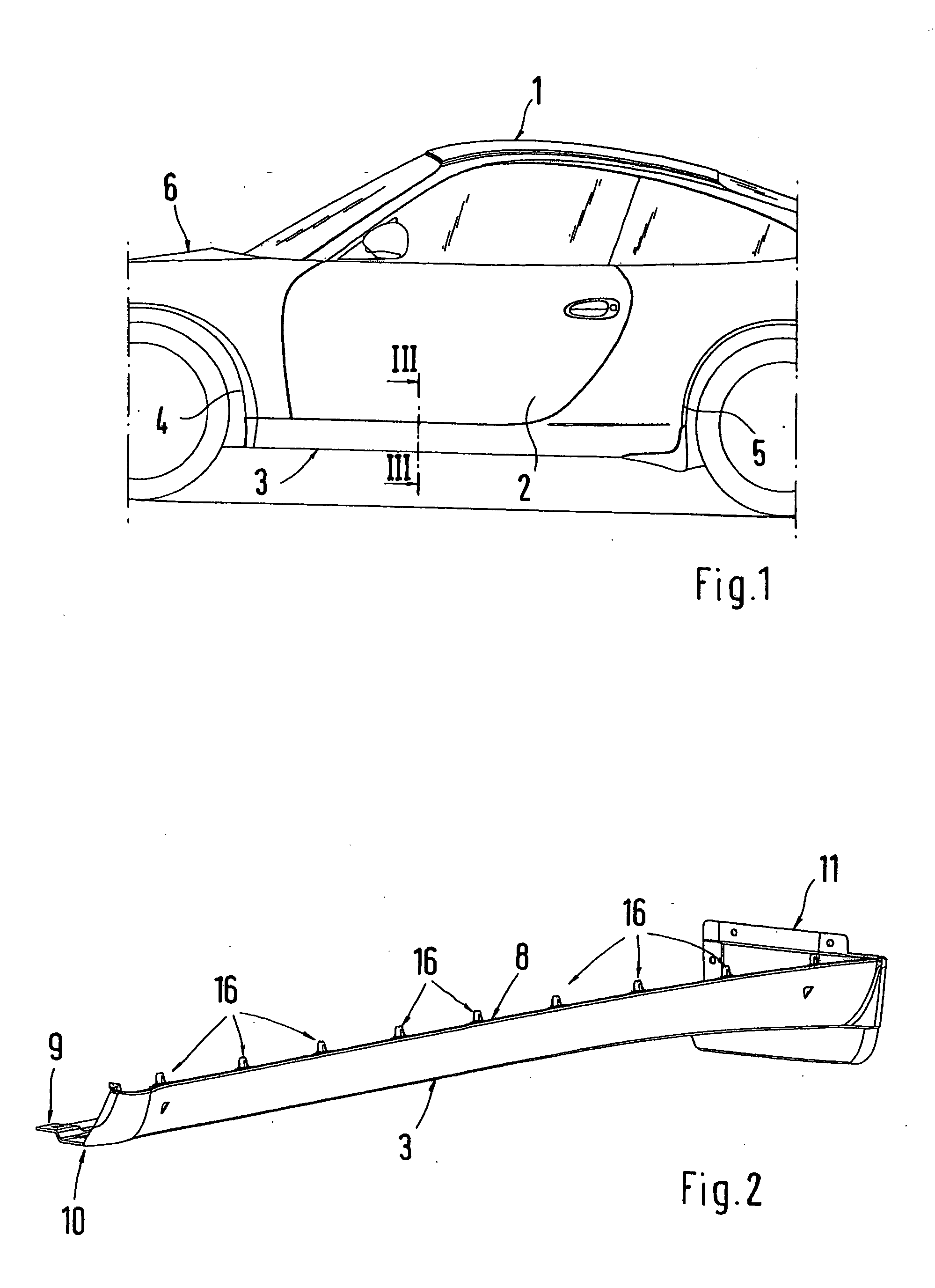

[0017]FIG. 1 shows a vehicle 1 consisting of an automobile that has an elongated sill panel 3 fitted below a side door 2. The sill panel 3 is a plastic part and extends in the longitudinal direction between a front wheel house 4 and a rear wheel house 5 of a mounting structure 6.

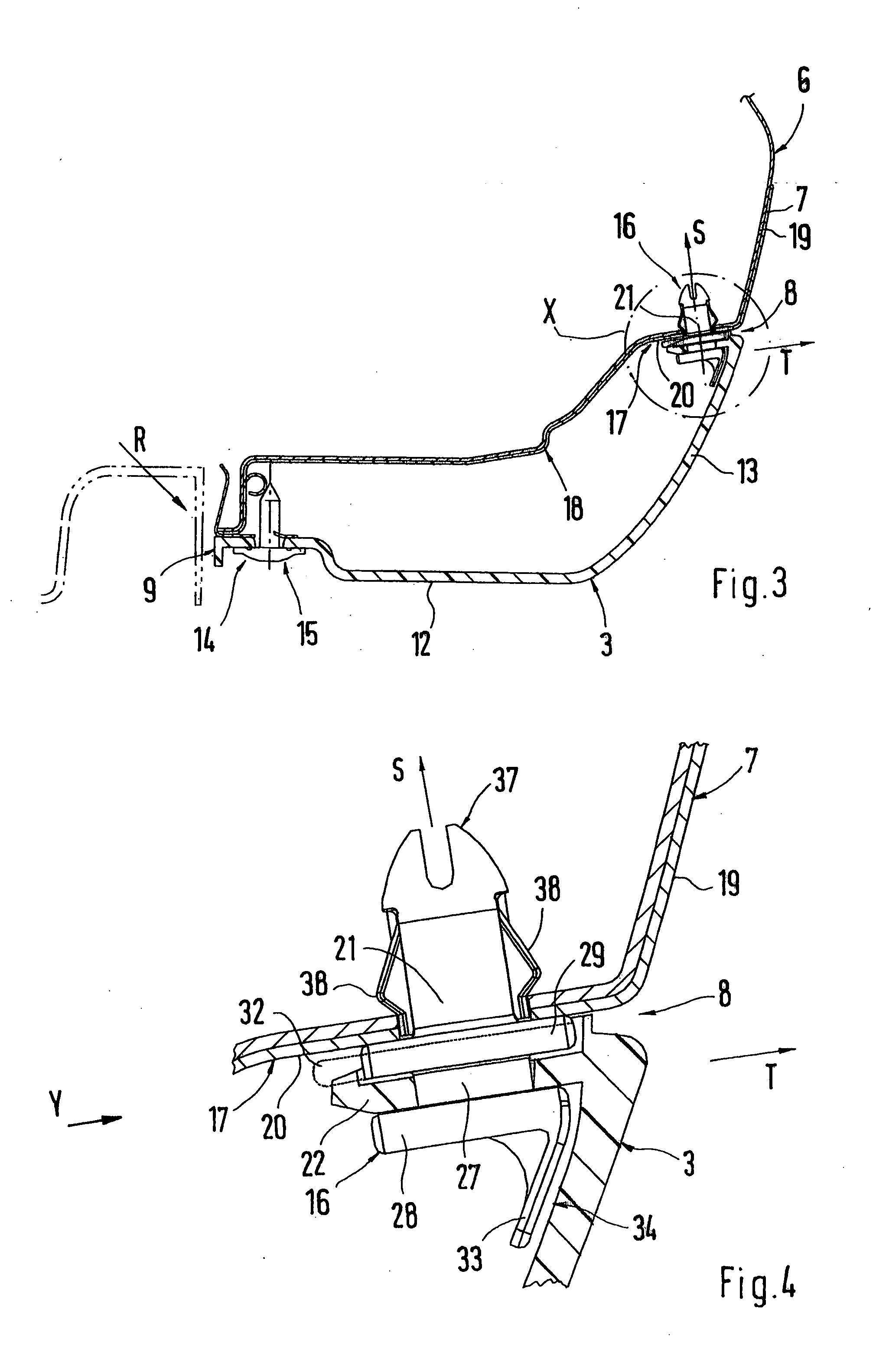

[0018] The sill panel 3 is fitted on the outside on an adjacent support part 7 of the mounting structure 6 and is detachably affixed locally in an upper border area 8 and in a lower border area 9 on the fixed mounting structure 6. The front edge 10 and the rear edge 11 of the sill panel 3 are detachably connected to the mounting structure 6. The support part 7 is formed by an outer plate of the panel, which can be provided with a PVC undercoating on the outside.

[0019] Seen in cross section, the sill panel 3 is comprised of a lower approximately horizontally aligned section 12 and a bent section 13 extending therefrom and projecting upward. The free end 14 of the lower section 12 of the sill panel 3, which ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com