Tennis shoes

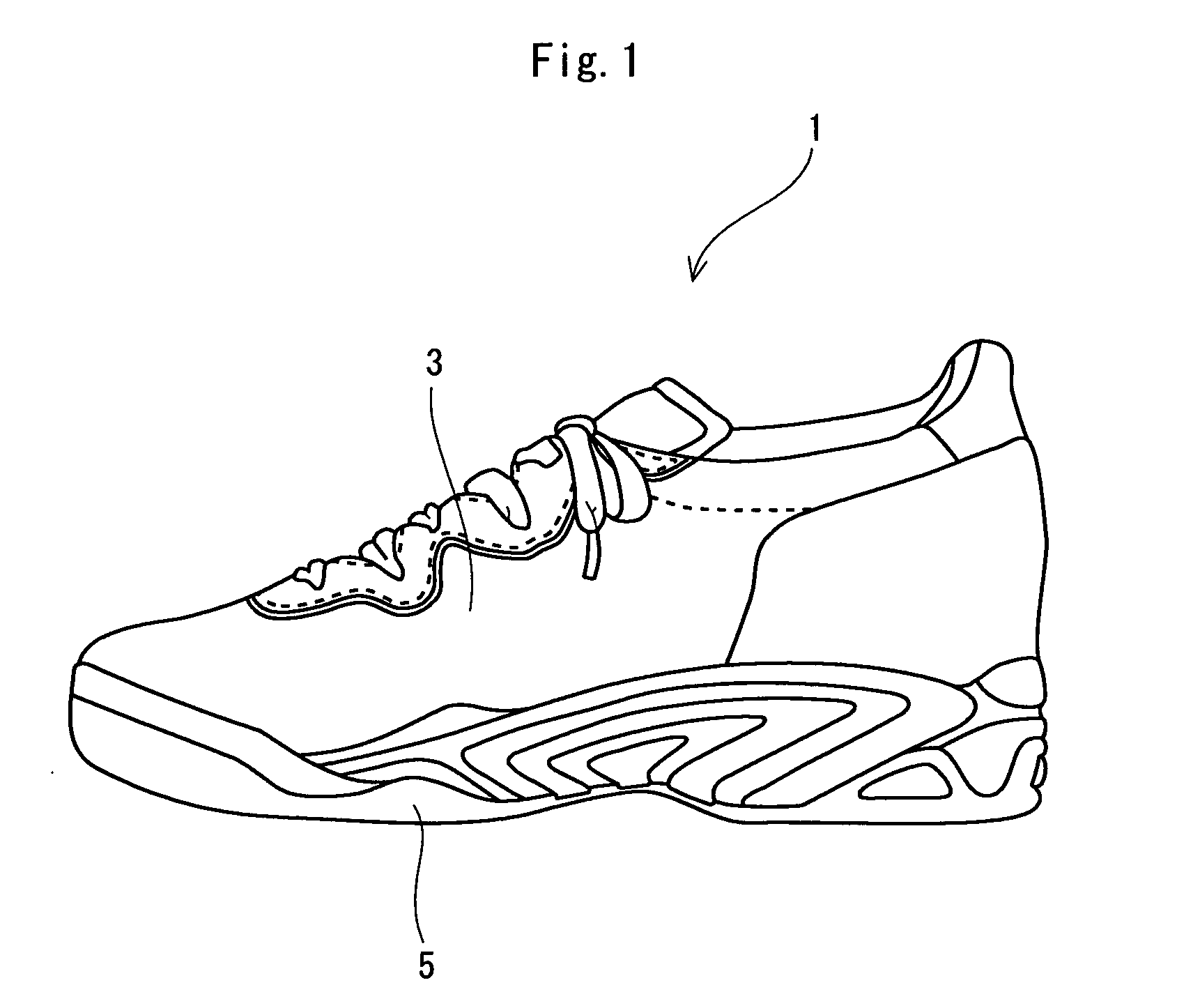

a technology for tennis shoes and uppers, applied in the field of tennis shoes, can solve the problems of insufficient consistency between non-slip performance and sliding performan

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

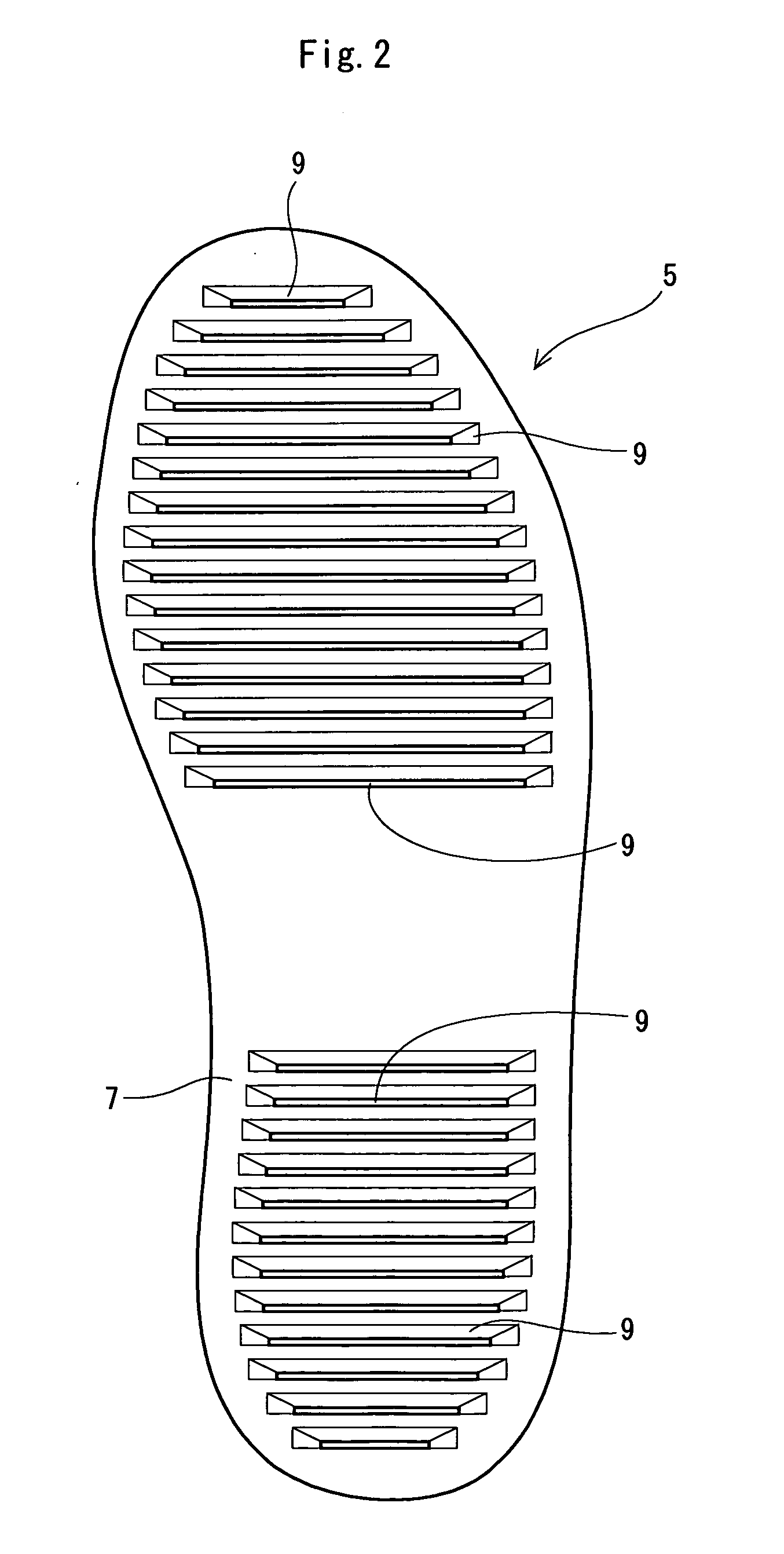

[0094] A rubber composition containing a styrene-butadiene copolymer as a base material was put in a mold to cause a crosslinking reaction over the rubber. Thus, a sole was obtained. The pattern of the bottom face of the sole is shown in FIG. 2. The sole has a large number of lateral ridges formed thereon. The lateral ridge has an inclination angle θa of 30 degrees, an inclination angle θb of 90 degrees, a height H of 3 mm and (L2 / L1) of 0.25. A midsole constituted by an ethylene-vinylacetate copolymer and an upper constituted by cotton were attached to the sole so that tennis shoes according to an example 1 were obtained.

example 4

[0096] Tennis shoes according to an example 4 were obtained in the same manner as in the example 1 except that the mold was changed and a sole comprising lateral and longitudinal ridges taking shapes shown in the following Table 1 was formed. The pattern of the sole is shown in FIG. 7.

[Test for Practical Use]

[0097] A player was caused to put on tennis shoes and to carry out the rally of tennis at an artificial turf court having sand (a trade name of “OMNICOURT” manufactured by SUMITOMO RUBBER INDUSTRIES, INC.). The easiness of a change in a direction, a nonslip performance in a start, a sliding performance and a tired feeling of legs were evaluated in five stages of “1” to “5”. The highest evaluation was indicated as “5”. An average value of the evaluations for ten players is shown in the following Table 1. As shown in the Table 1, an outsole according to each of the examples has excellent evaluation results for all items.

TABLE 1Result of evaluationCompara.Compara.Example 1Examp...

experiment 2

[Experiment 2]

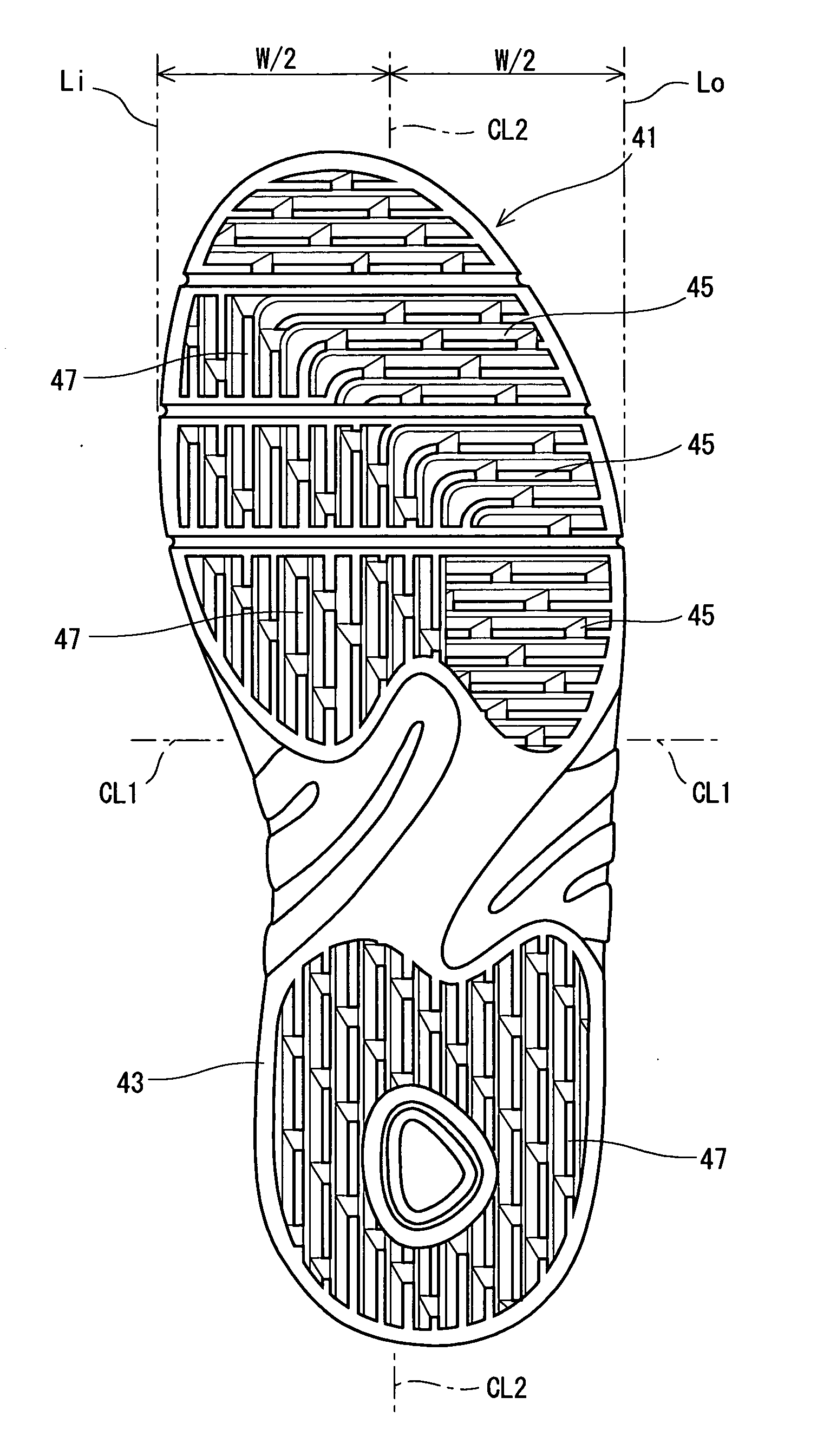

Example 5

[0098] A rubber composition containing a styrene-butadiene copolymer as a base material was put in a mold and was vulcanized. Thus, a sole was obtained. The pattern of the bottom face of the sole is shown in FIG. 9. The sole has a plurality of lateral ridges and a plurality of longitudinal ridges formed thereon. A ratio R1 of the contact area of the lateral ridge to the total contact area of the ridges in a toe portion is 50% and a ratio R2 of the contact area of the longitudinal ridges to the total contact area of the ridges in an inside portion is 90%. A midsole constituted by an ethylene-vinylacetate copolymer and an upper constituted by cotton were attached to the sole so that tennis shoes according to an example 5 were obtained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com