Modular rim board for floor and rafter systems

a technology of modular rim boards and floor and roof frames, which is applied in the direction of girders, joists, building roofs, etc., can solve the problems of reducing installation errors, saving time, and increasing costs, so as to improve the overall performance, improve the quality, performance and efficiency of i-joists and other floor and roof framing systems, and improve the overall performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

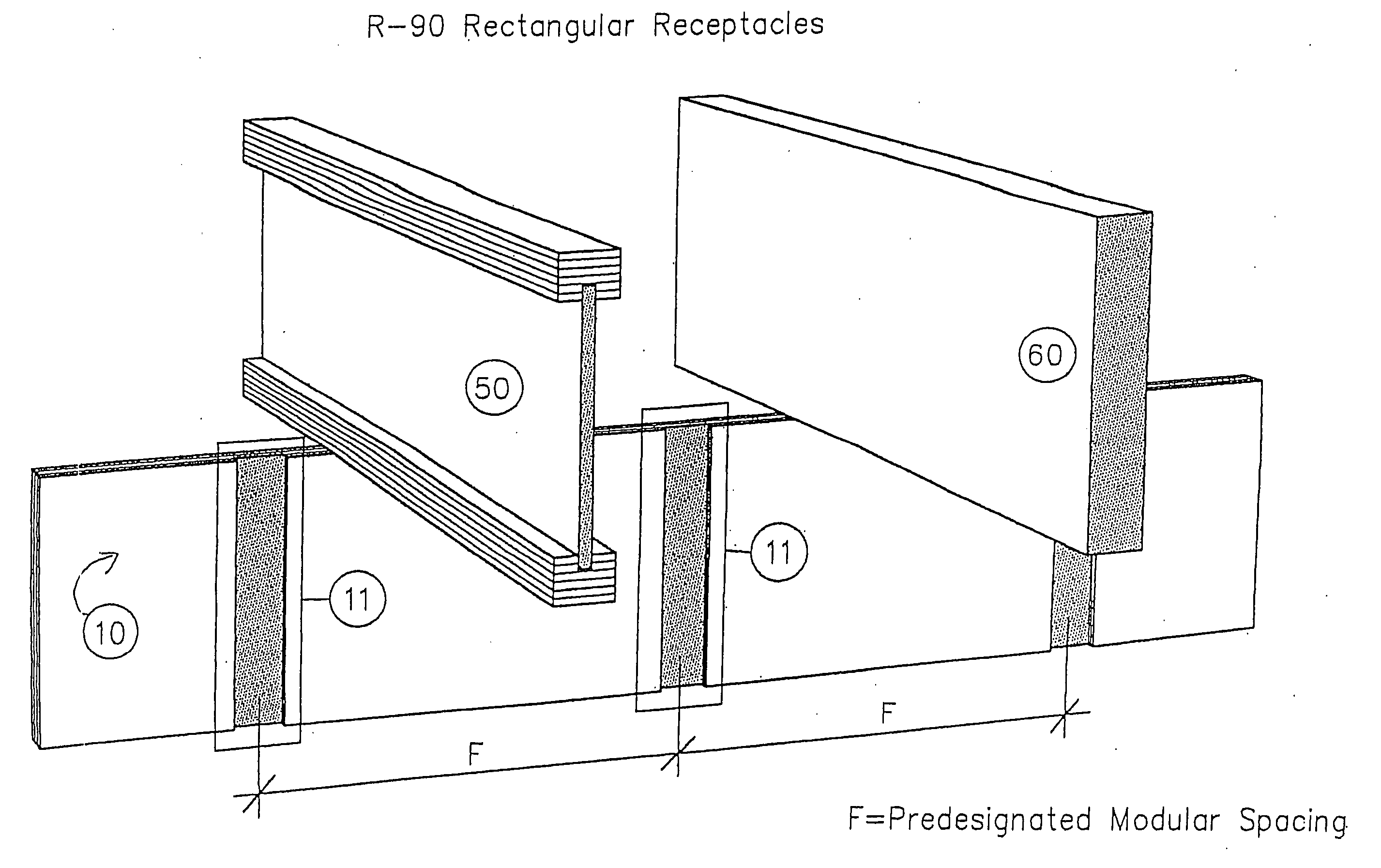

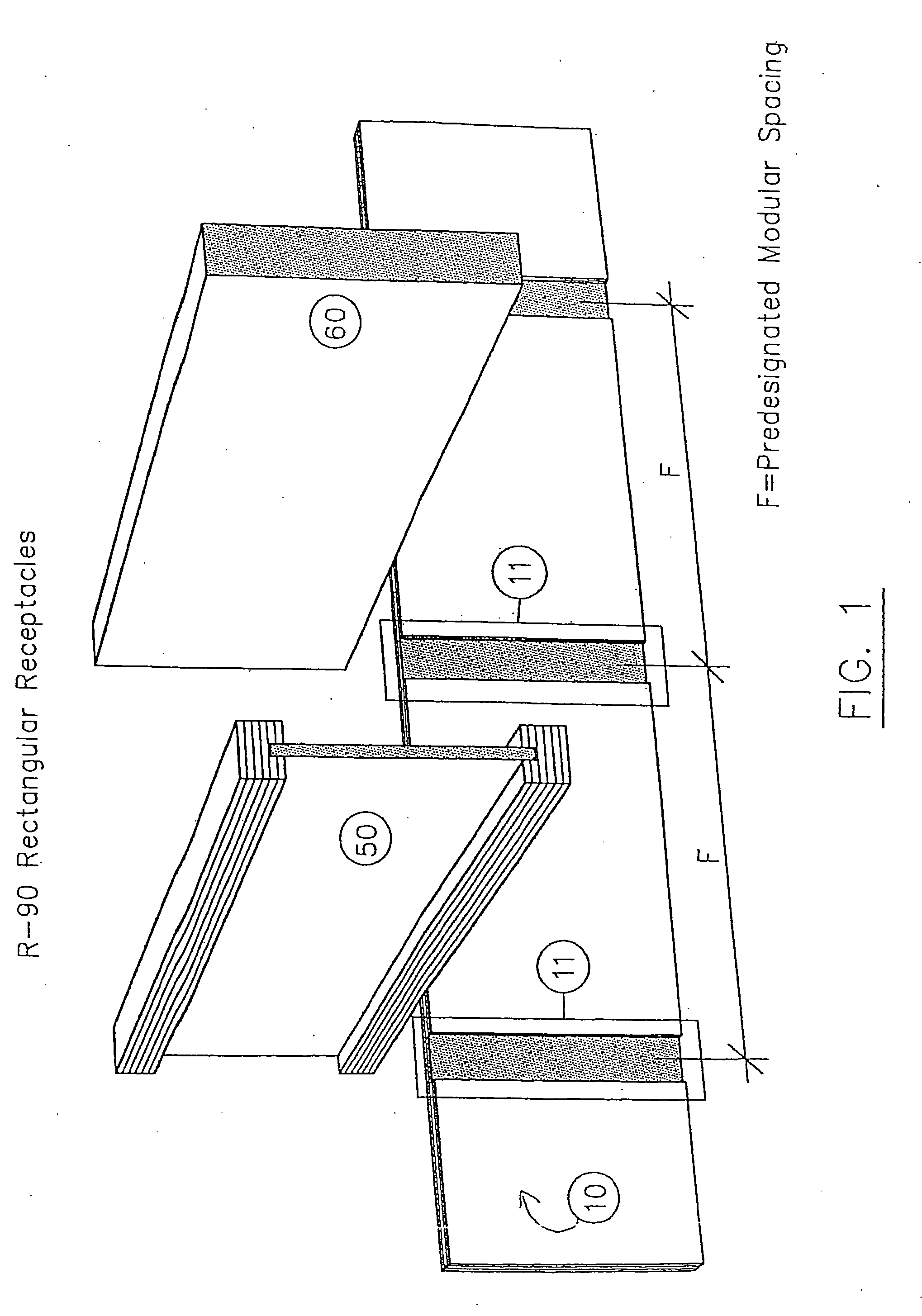

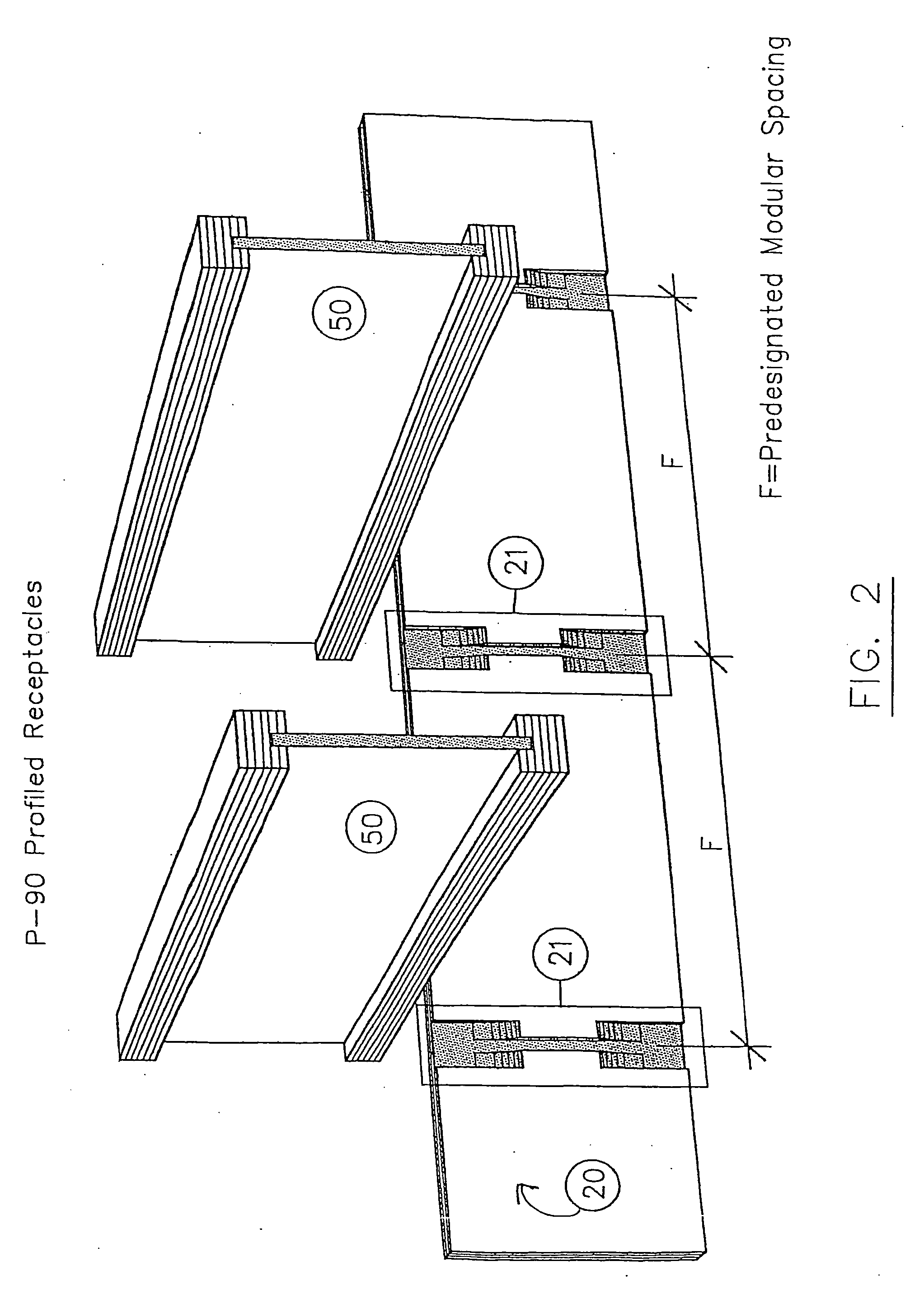

[0027] Referring to the Figures, there are shown several, but not the only, embodiments of the invented RIM BOARD for use with manufactured dimensionally rectangular joists and wood I-joists, and methods of installing the same. The preferred rim board, which is currently called the “Speed-I-Lock™” Rim Board, comprises modular recessed receptacles that are designed and engineered to accept the end profiles of I-joists and other manufactured joists made from solid lumber, reconstituted wood products and other approved materials regardless of dimensional size, shape and / or manufacturer. The preferred receptacle designs feature pre-measured joist spacing to facilitate accuracy and accelerate onsite installation time. The rim boards may be manufactured, for example, from solid softwood and / or hardwood lumber; laminated veneers, reconstituted and composite wood products using various types and / or combinations of adhesive bonding systems; formed by extruding and / or platens compressing wood...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com