Method of achieving high pretilt angles in a lilquid crystal cell

a liquid crystal cell and high pretilt angle technology, applied in the direction of thin material processing, instruments, coatings, etc., can solve the problems of difficult to obtain large values of (0) from 10°-80°, and all of these methods are, however, impractical for mass production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

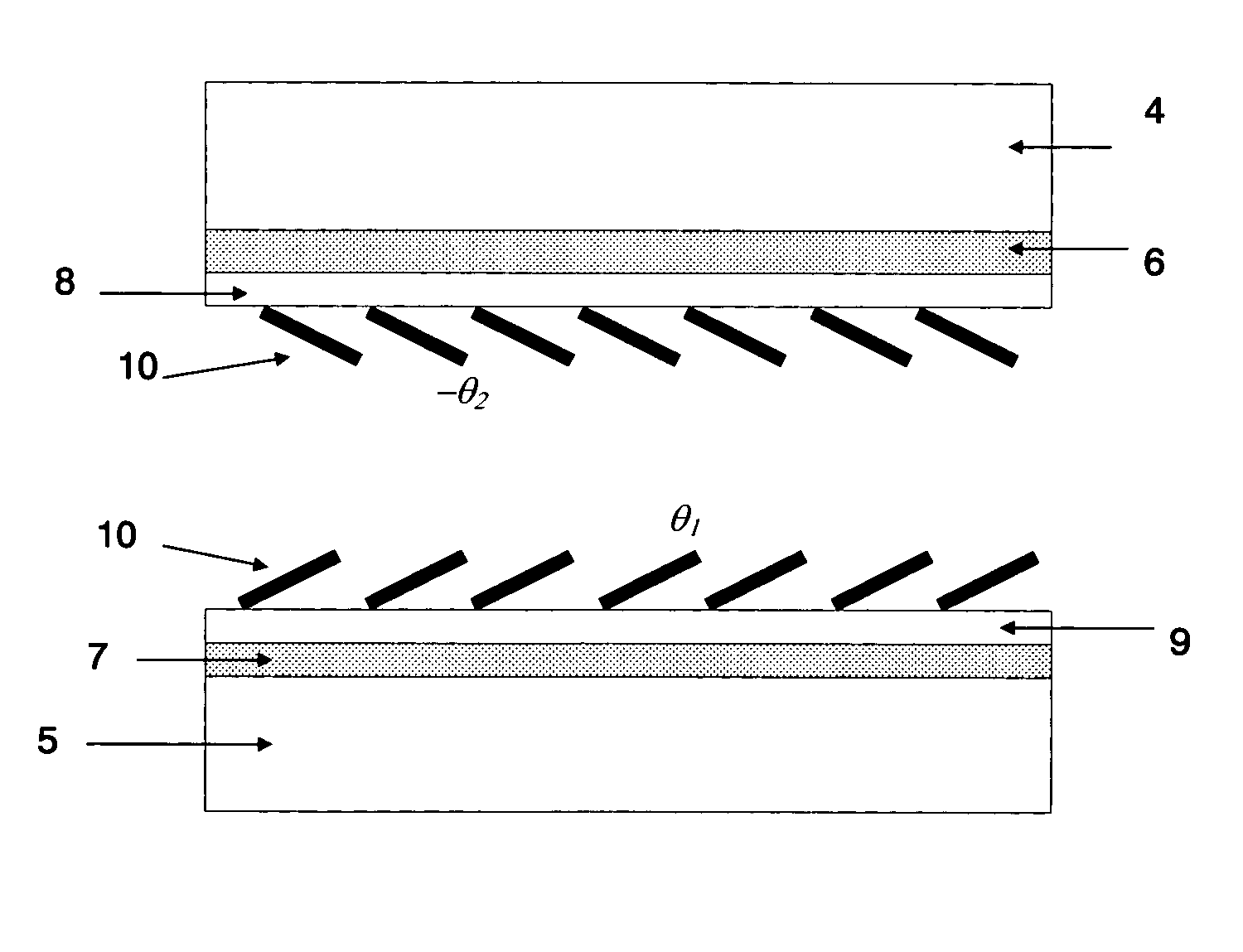

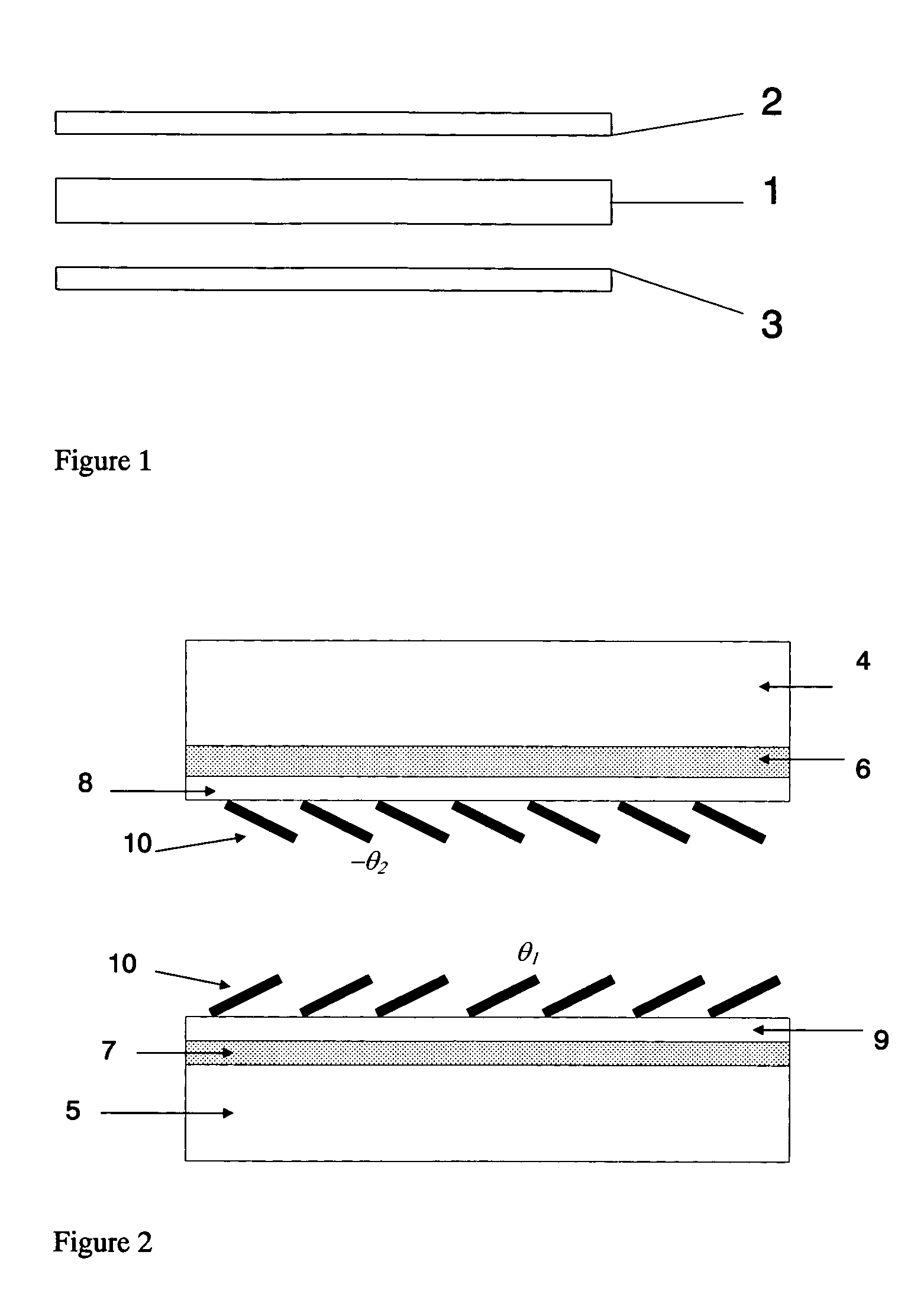

[0014] A liquid crystal display is usually made of a liquid crystal cell 1 and two polarizers 2, 3. The simplest liquid crystal cell is composed of top and bottom glass plates 4, 5, transparent conductive electrodes 6, 7, alignment layers 8, 9 and the liquid crystal layer 10. The angles of the liquid crystal layer on the contact surfaces with the alignment layers are called the pretilt angles. As shown in FIG. 2, the pretilt angles on the top and bottom layers can be different. The transmission or reflectance of light by the liquid crystal cell is determined completely by knowing the polarizer angles α and γ, and the alignment condition of the liquid crystal layer 10. The liquid crystal layer is defined completely by the tilt angle θ(z) and twist angle φ(z) distributions of the liquid crystal director vector n as a function of its position in the one-dimensional case, and θ(x,y,z) and φ(x,y,z) in the three-dimensional case.

[0015] The electrodes 6, 7 and the alignment layers 8, 9 ar...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| pretilt angles | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com