Polyimide liquid crystal direct action membrane with fluorine-contained surface and preparation method thereof

A technology of liquid crystal alignment film and polyimide, which is applied in the field of fluorine-containing polyimide liquid crystal alignment film and its preparation, and achieves the effects of wide application, wide range of pretilt angles, and easy polymerization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

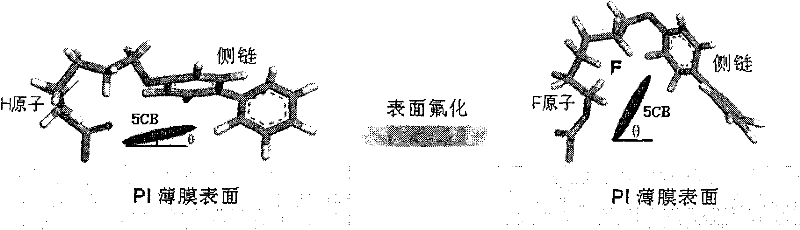

Problems solved by technology

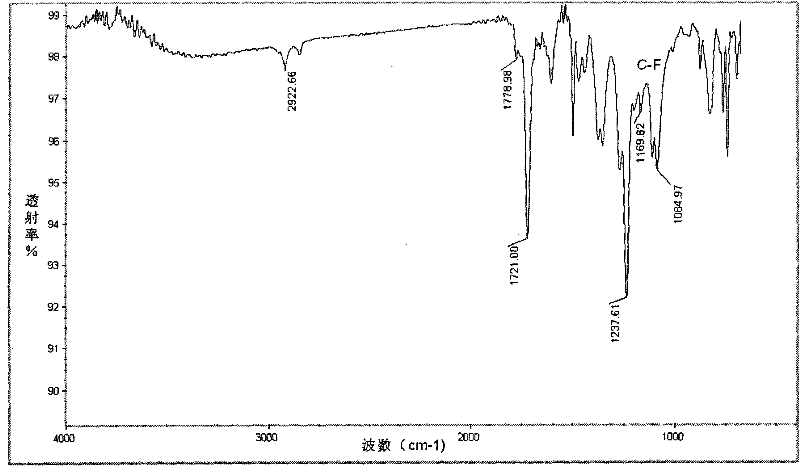

Method used

Image

Examples

Embodiment 1

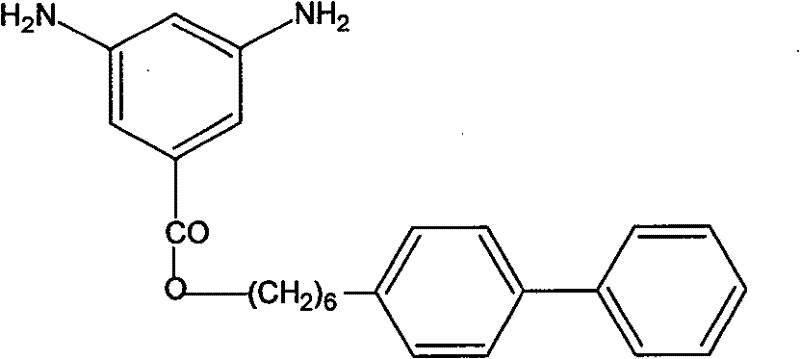

[0037] First 2 molar parts of 3,5-diaminobenzoic acid {6-[4'-(phenyl)phenoxy)]hexyl} ester and 8 molar parts of 4-4' diaminodiphenyl ether diamine were added to 30 Add mole parts of m-cresol, and stir until dissolved under nitrogen protection, then add 10 mole parts of 3,3',4,4'-tetracarboxylic diphenyl ether dianhydride at a temperature of 25°C, and stir for 2 hours , and then raised the temperature to 180° C. for imidization reaction for 4 hours to obtain a uniform and transparent polyimide solution.

[0038] The chemical structural formula of this polyimide molecule is:

[0039]

[0040] where n:m=8:2

[0041] Dilute the obtained polyimide solution with m-cresol to a mass percent concentration of 5%, then apply the polyimide solution evenly on the substrate by high-speed spin coating, and under vacuum conditions, prior to the temperature of 100 The solvent was removed at ℃ for 1 hour, and then cured at 225 ℃ for 3 hours to obtain a side chain type polyimide liquid crysta...

Embodiment 2

[0044] Since the conditions of the side-chain type polyimide liquid crystal alignment film prepared in this example are the same as those in Example 1, it is omitted here.

[0045] The fluoridation treatment conditions of this embodiment are: the temperature is 25°C, the treatment time is 5 minutes, the partial pressure of fluorine gas in the reactor is maintained at 45KPa, and the rest are the same as in Example 1, omitted.

Embodiment 3

[0047] Since the conditions of the side-chain type polyimide liquid crystal alignment film prepared in this example are the same as those in Example 1, it is omitted here.

[0048] The fluorination treatment conditions of this embodiment are: temperature 100° C., treatment time 5 minutes, fluorine partial pressure in the reactor kept at 20 KPa, and the rest are the same as in Example 1, omitted.

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com