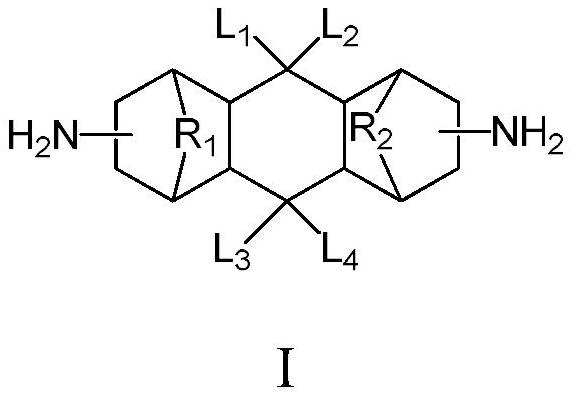

Diamine compound as well as preparation method and application thereof

A kind of amine compound and compound technology, applied in the field of diamine compound and its preparation, can solve the problems of image afterimage, difficult ionic charge detachment, etc., and achieve the effect of simple preparation process, low residual DC charge, and easy promotion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

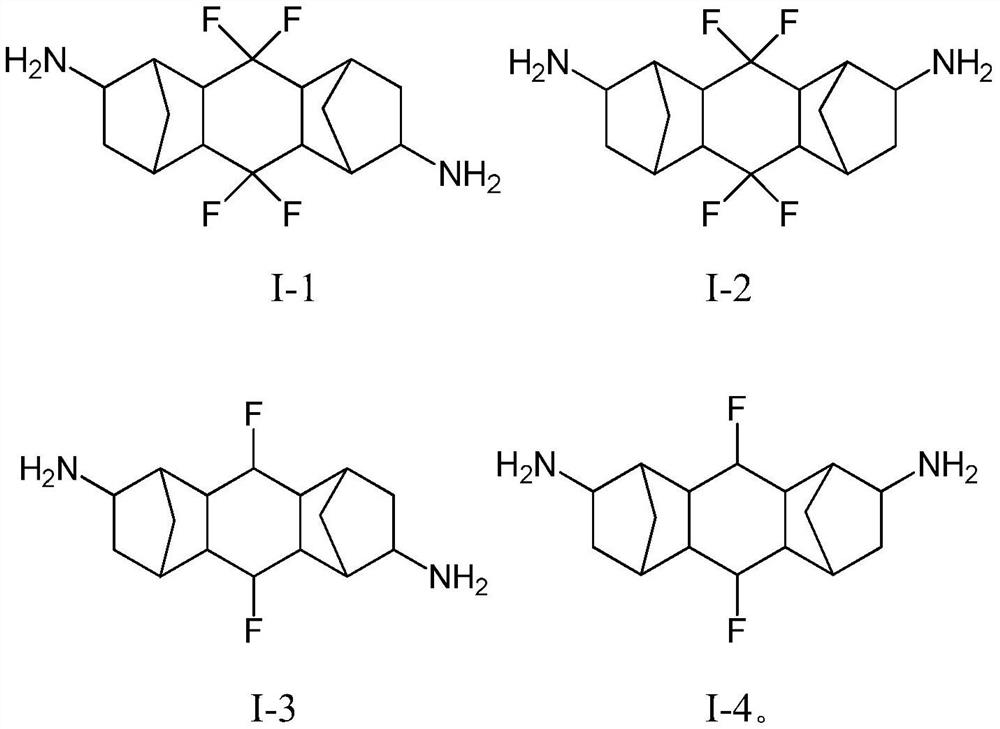

[0058] A diamine compound, its structural formula is:

[0059]

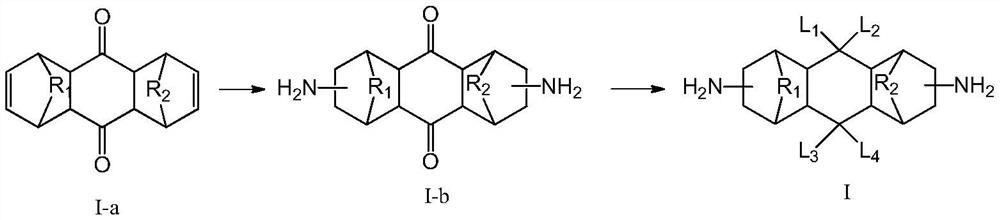

[0060] The synthetic route for preparing compound I-1 is as follows:

[0061]

[0062] Specific steps are as follows:

[0063] (1) Synthesis of compound I-b-1

[0064] Add 28.8g of compound I-a-1 and 200ml of tetrahydrofuran into the reaction kettle, pass ammonia gas at room temperature until the pressure is 0.5MPa-1.0Mpa, raise the temperature to 200°C for 6 hours, lower the temperature and reduce the pressure, and quench the reaction with saturated aqueous sodium bicarbonate solution. Conventional post-treatment, recrystallization from n-heptane gave 28.6 g of off-white solid (compound I-b-1), HPLC: 99.6%, yield 87.2%;

[0065] (2) Synthesis of compound I-1

[0066] Under the protection of nitrogen, add 25.0g I-b-1 and 200ml tetrahydrofuran to the reaction bottle, add 66.5g diethylaminosulfur trifluoride dropwise under temperature control -70℃~-60℃, and react under temperature control -70℃~-60℃ 1 hour...

Embodiment 2

[0070] A diamine compound, its structural formula is:

[0071]

[0072] The synthetic route for preparing compound 1-3 is as follows:

[0073]

[0074] (1) Synthesis of compound I-c-1

[0075] Add 55.0g of compound I-b-1 and 250ml of tetrahydrofuran into the reaction bottle, add 13.5g of potassium borohydride aqueous solution dropwise at a temperature of 10°C to 30°C, and react for 3 hours at a temperature of 50°C to 60°C after dropping, then add dilute hydrochloric acid to quench the reaction. After conventional post-treatment, recrystallization from n-heptane gave 51.5 g of off-white solid (compound I-c-1), HPLC: 99.2%, yield 92.8%;

[0076] (2) Synthesis of compound I-3

[0077] Under the protection of nitrogen, add 50.0g I-c-1, 300ml tetrahydrofuran to the reaction bottle, add 86.8g diethylaminosulfur trifluoride dropwise under temperature control -70℃~-60℃, and react under temperature control -70℃~-60℃ 1 hour, naturally return to -30°C, add saturated aqueous sodi...

experiment example 1

[0081] 15.9 grams (0.05 moles) of compound I-1, 9.8 grams (0.05 moles) of CBDA were dissolved in 92.8 grams of NMP (N-methylpyrrolidone), reacted at room temperature for 12 hours, and then added 348 grams of NMP to carry out Dilute to obtain a polyamic acid solution (specific viscosity: 0.57dl / g).

[0082] Then, the polyamic acid solution was spin-coated on a glass substrate with a transparent electrode at 3000 rpm.

[0083] Then, it was heated at 200° C. for 30 minutes to form a polyimide film, which was assembled into a liquid crystal cell assembled in a parallel direction by using a spacer of 40 μm. After pouring liquid crystal (model: BYLC-1000, manufactured by Bayi Space-Time Liquid Crystal Technology Co., Ltd.), the liquid crystal cell rotates between the orthogonal Nicol prisms and presents a state of total darkness, which is obtained by using a pre-tilt angle measuring machine. The value of the pretilt angle is 87°; after testing, the residual DC charge is 93mV.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com