Polishing fixture for simultaneous loading of a plurality of optical connectors and fiber stubs and a method of loading

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Example

[0067] The principles and execution of a method according to the present invention, and the operation and properties of the fixture, loading plate, fiber stub insertion tool and fiber stub inversion assembly described thereby may be understood with reference to the drawings, wherein like reference numerals denote like elements through the several views and the accompanying description of non-limiting, exemplary embodiments.

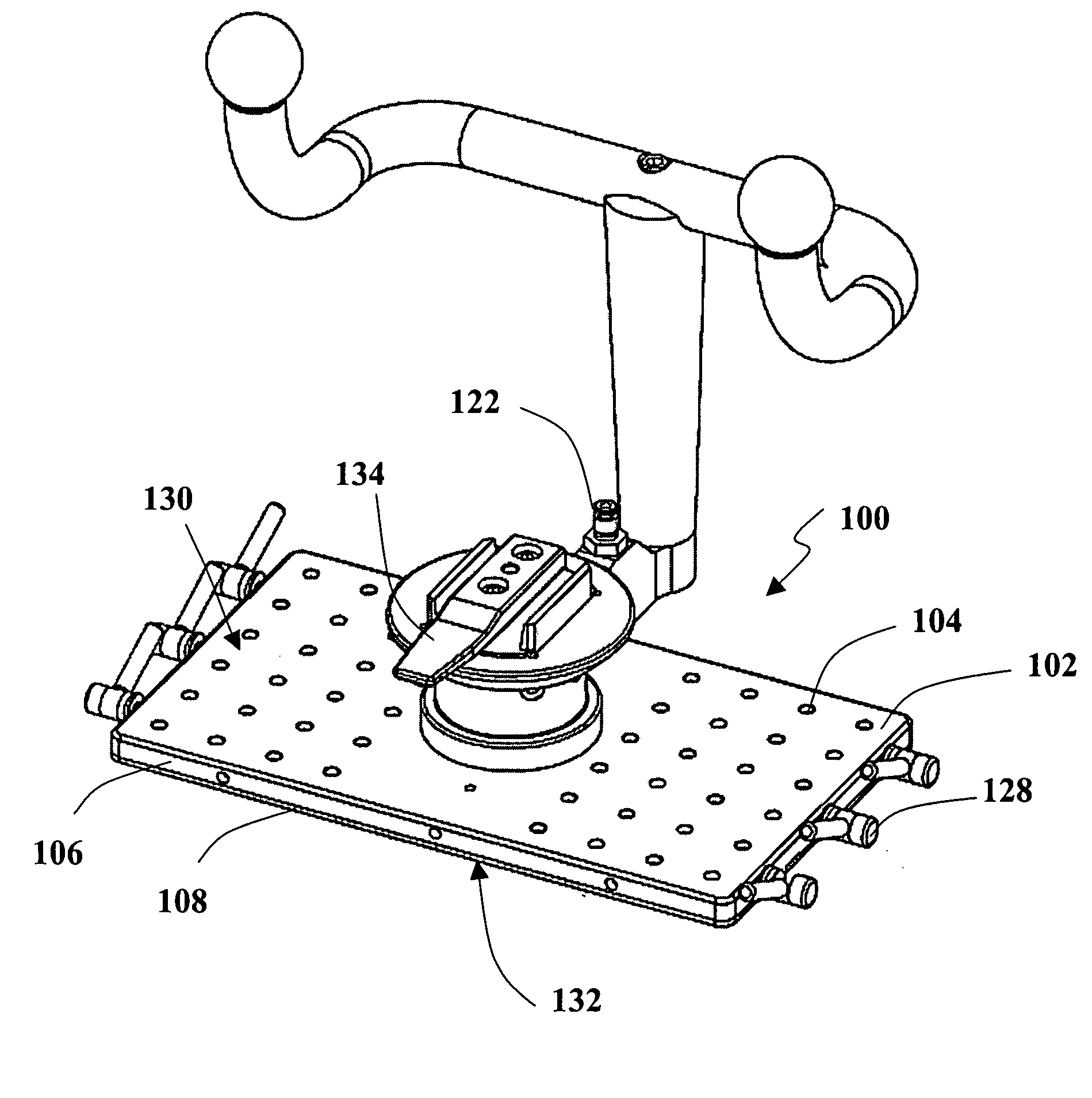

[0068] Reference is now made to FIGS. 2, 3 and 4 that illustrate an exemplary embodiment of the fixture for simultaneously clamping a plurality of optical fiber ferrules or fiber stubs for polishing of the present invention. Polishing fixture 100 optionally and preferably includes a plate assembly 106 having an upper surface 130, a lower surface 132 and a plurality of ferrule-receiving bores 104 disposed across the upper surface and extending from upper surface 130 to lower surface 132, each ferrule-receiving bore 104 for receiving a ferrule 138 (FIG. 4). Fixture...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap