Bastions for force protection and military applications

a technology for force protection and military applications, applied in the field of bases, can solve the problems of destroying the protection afforded, failing to meet the requirements of fire resistance, and prior art protection barriers suffering from a number of additional drawbacks, and achieve the effect of improving the protection offered

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

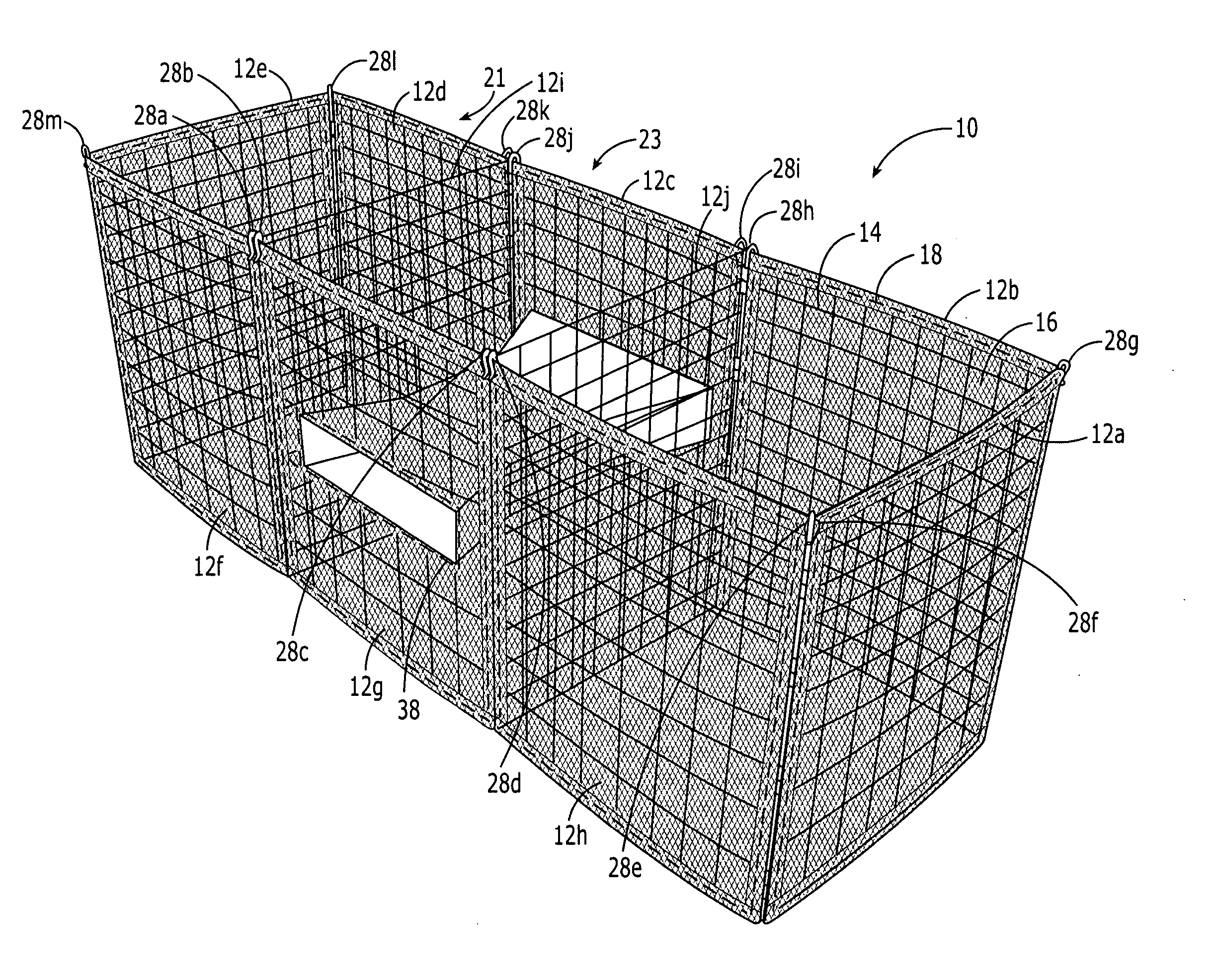

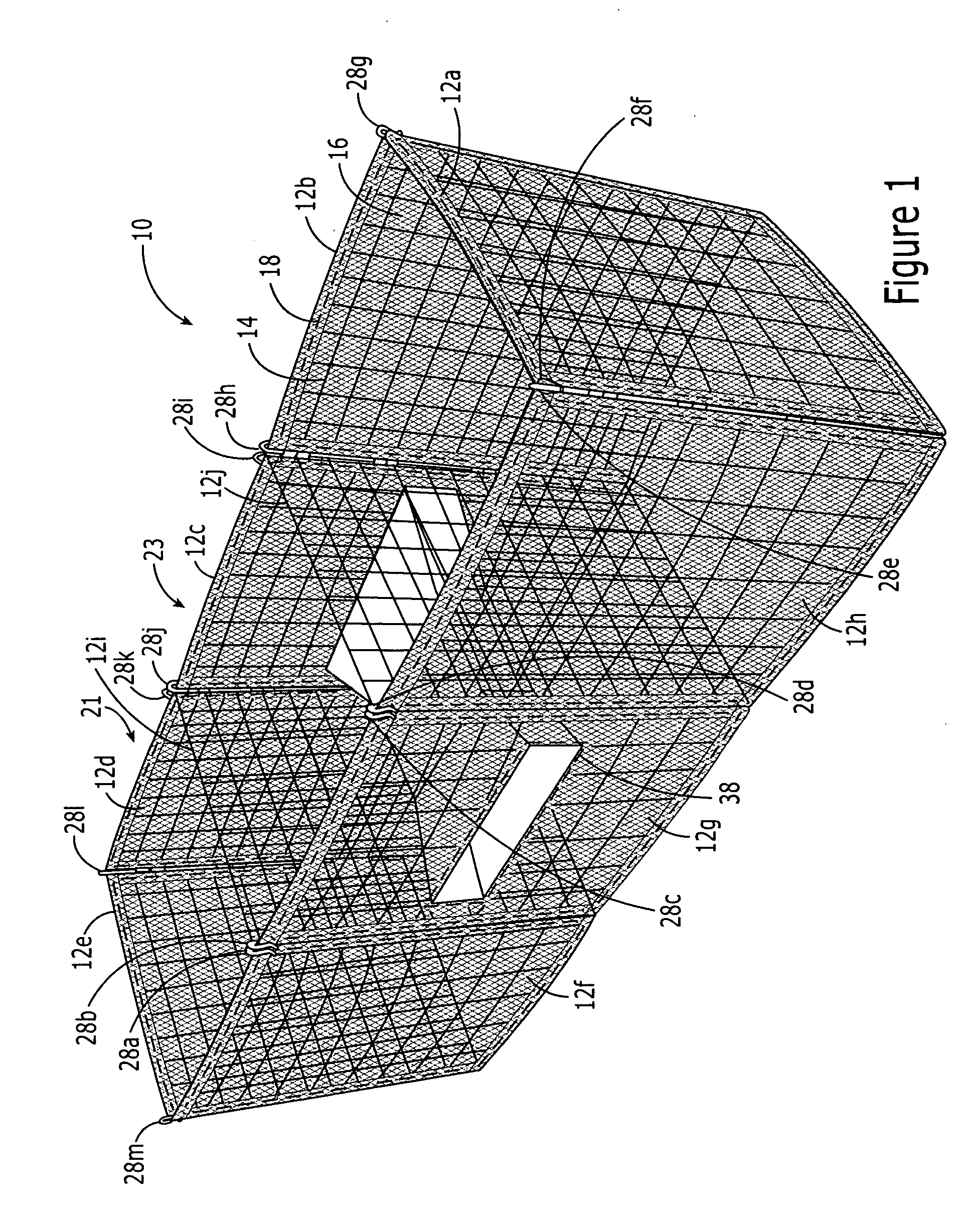

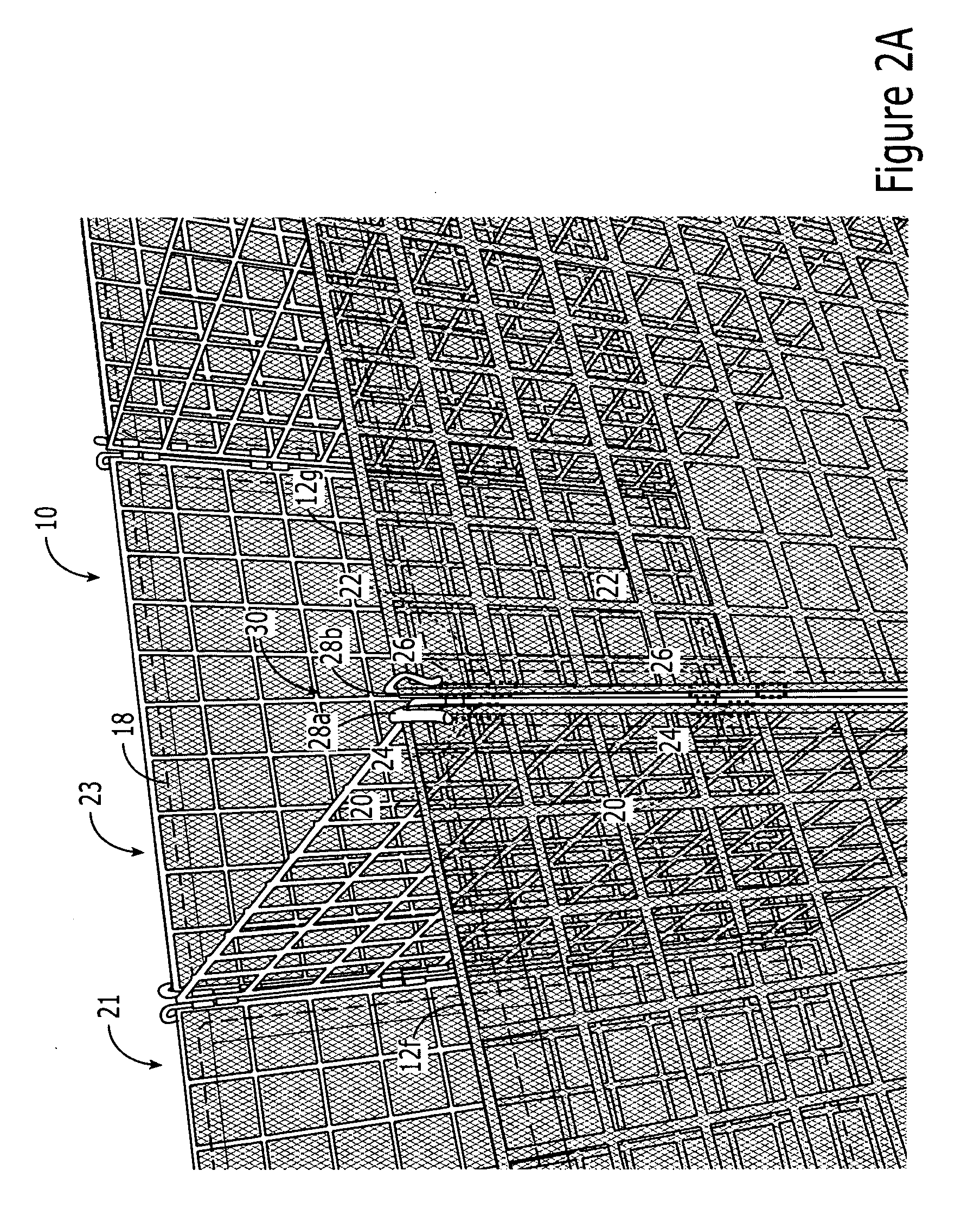

[0030] The basic components of an exemplary embodiment of a bastion of the present invention, generally designated 10, are panels 12a-12j. The panels 12a-12j may be made, for example, from a welded wire frame including wires 14 having, for example, diameters between 3 mm and 8 mm. The wires 14 may, for example, have a rectangular pattern with center to center distance depending on load, for example, 5 cm to 20 cm. The wires 14 may be lined with a metal screen mesh 16 of expanded metal or wire knitted mesh, stitched to the wire frame or connected using staples 18. Alternatively, the panels 12a-12j may be configured without a mesh. However, in this case the wires 14 are spaced close together so as to prevent a filler, used to fill the bastion 10, such as sand crushed rocks, granulars, etc., from spilling out.

[0031] In the example embodiment of the present invention illustrated in FIG. 1, exterior panels 12a-12h and interior panels 12i and 12j form a foldable three-cell structure of r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com