Yo-yo bearing member

a bearing member and yo-yo technology, applied in the field of yo-yos, can solve the problems of yo-yo play type, difficulty in setting a wide enough string gap to accommodate a plurality of lays of string, premature return of the yo-yo to the player's hand, etc., to achieve the effect of economic and light weight, effective snaring, and surface coefficient of friction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

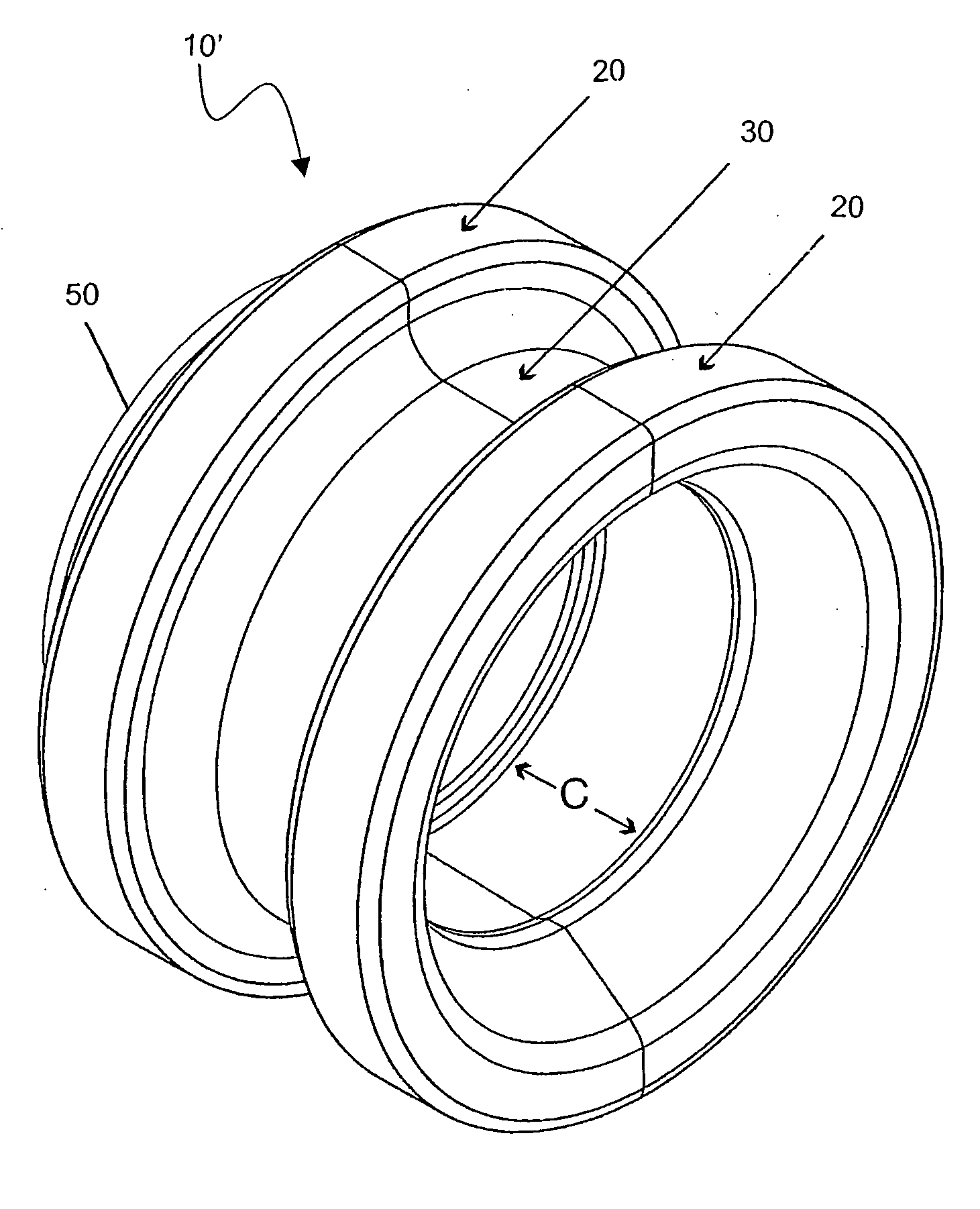

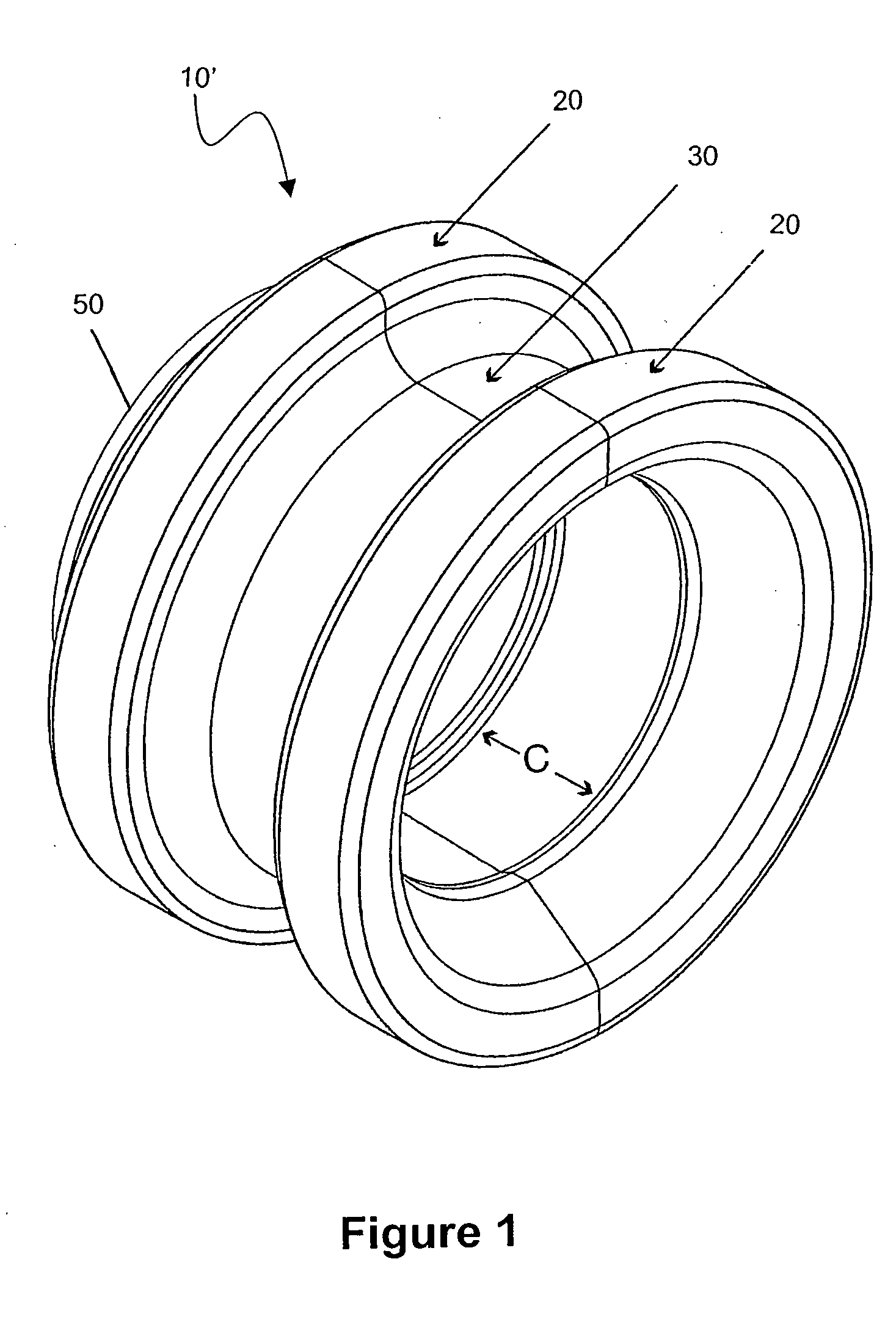

[0042] With reference to the drawings, wherein like numerals represent like parts, FIG. 1 shows an isometric view of a bearing sleeve 10 or ball-bearing outer race of an embodiment of the present invention wherein the outer quasi-cylindrical face 20 is provided with a broad concave shaped outer surface 30 able to accept more than one lay of string. The distance C is the axial width of a contained bearing 40 in the case of a bearing sleeve, or of the inner race and the ball-race with dust-covers in the case of being a ball-bearing outer race.

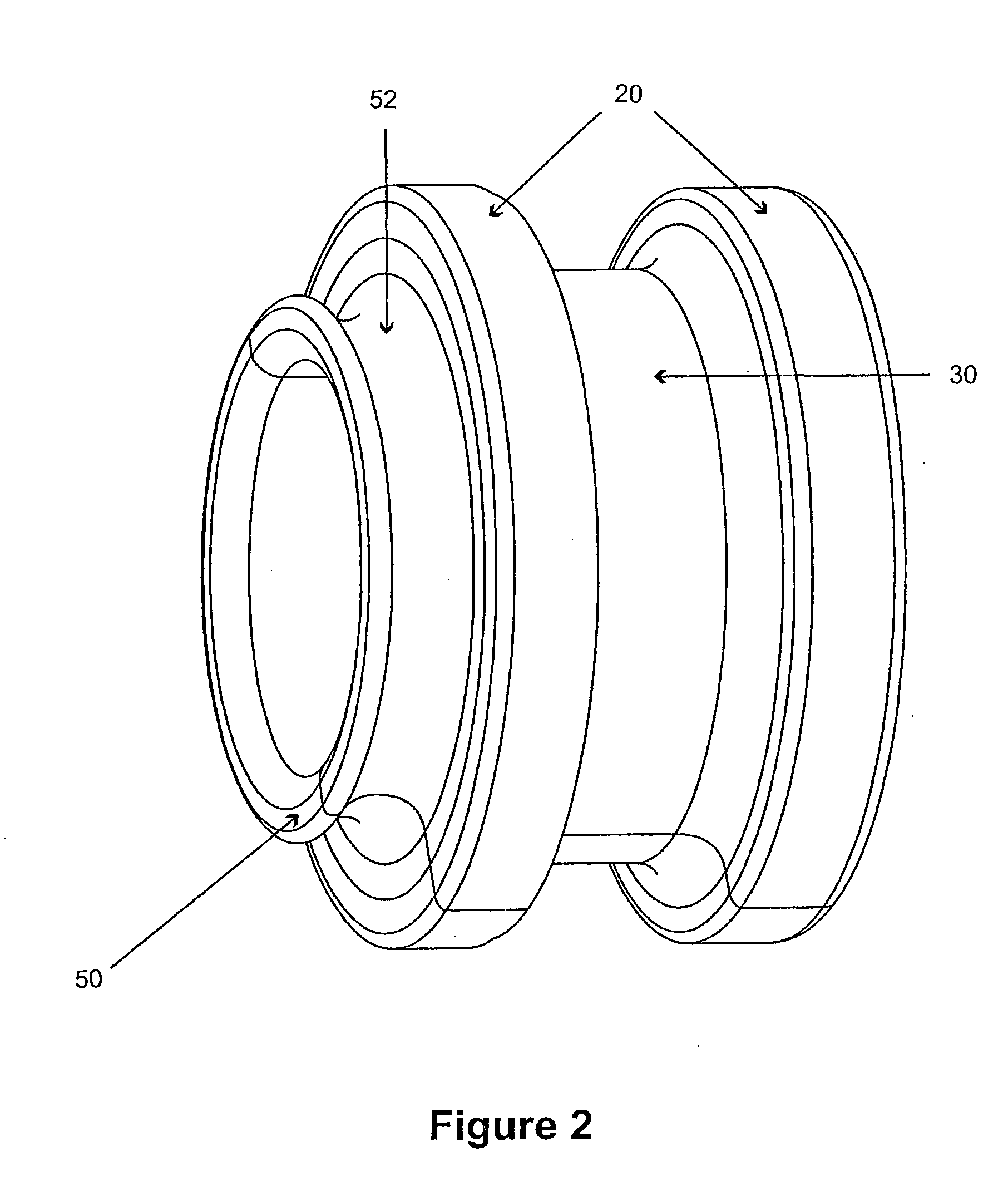

[0043]FIG. 2 shows another view of the same embodiment, rotated horizontally through some 45 or so degrees from the previous figure, which shows the extension 50 of the outer surface 20 to accommodate a friction braking member (not shown) to be seated in groove 52.

[0044] Another embodiment of a bearing sleeve 10 is illustrated in FIGS. 3 and 4.

[0045] With reference to FIGS. 5 and 6, a yo-yo 100 which employs the bearing sleeve 10 includes yo-y...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com