Illuminator for dark field inspection

a technology of illumination and dark field, applied in the field of inspection of materials, can solve the problems of affecting the overall performance of the inspection system, the sensitivity of the inspection system can vary, and the “ring-lamp” device, similar to the one used to illuminate dark-field microscopes, cannot work well for the inspection system of dark-field wafers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

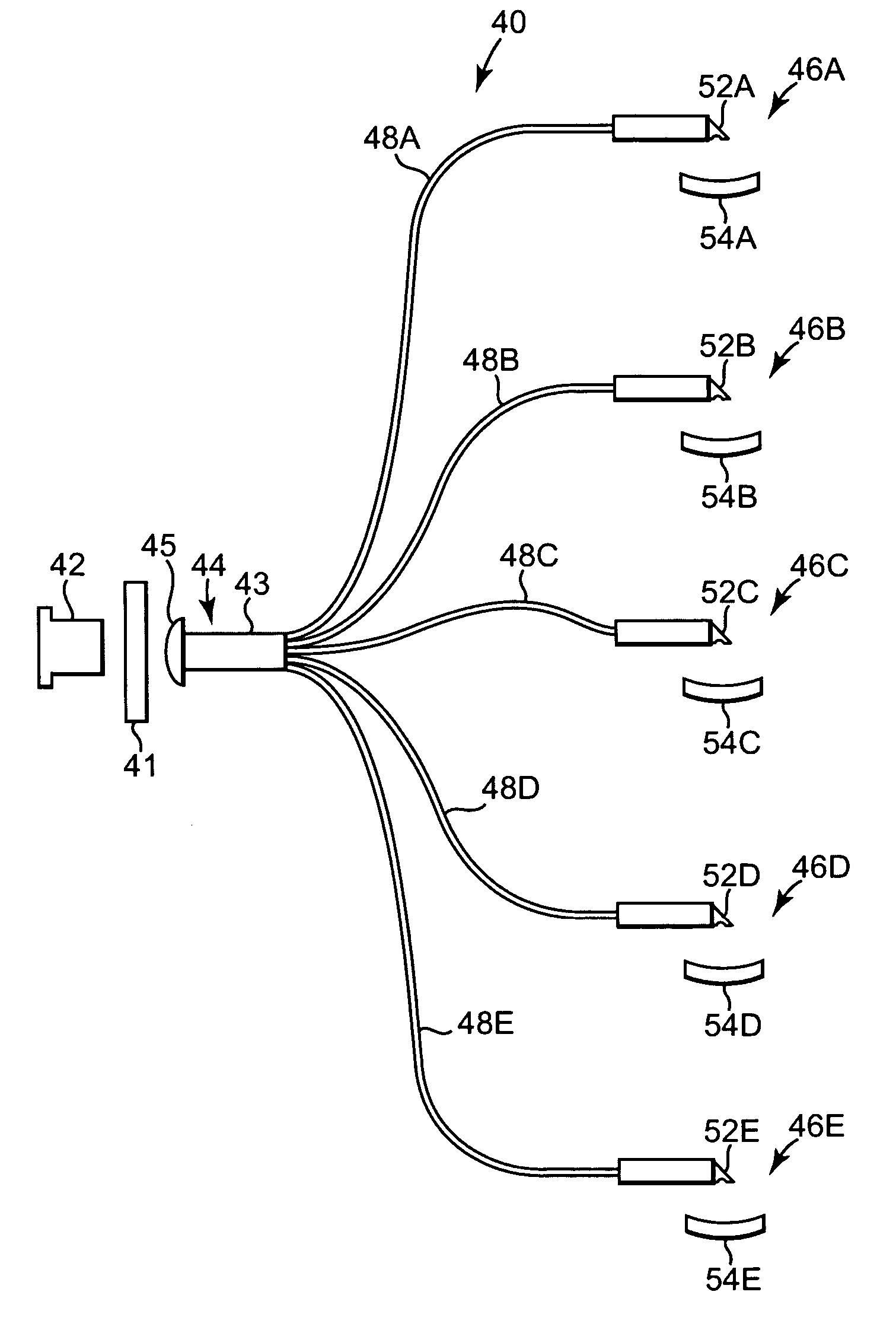

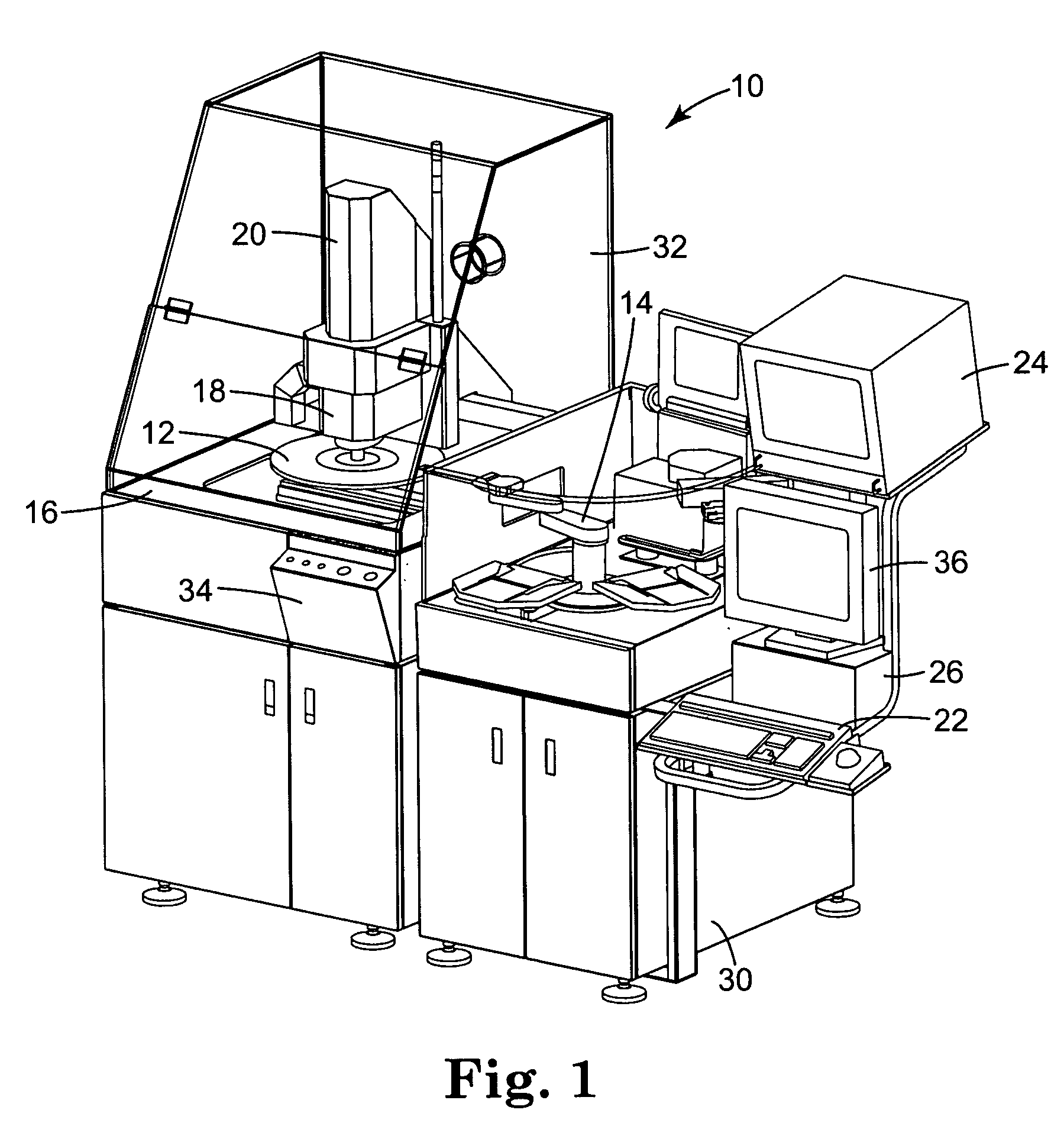

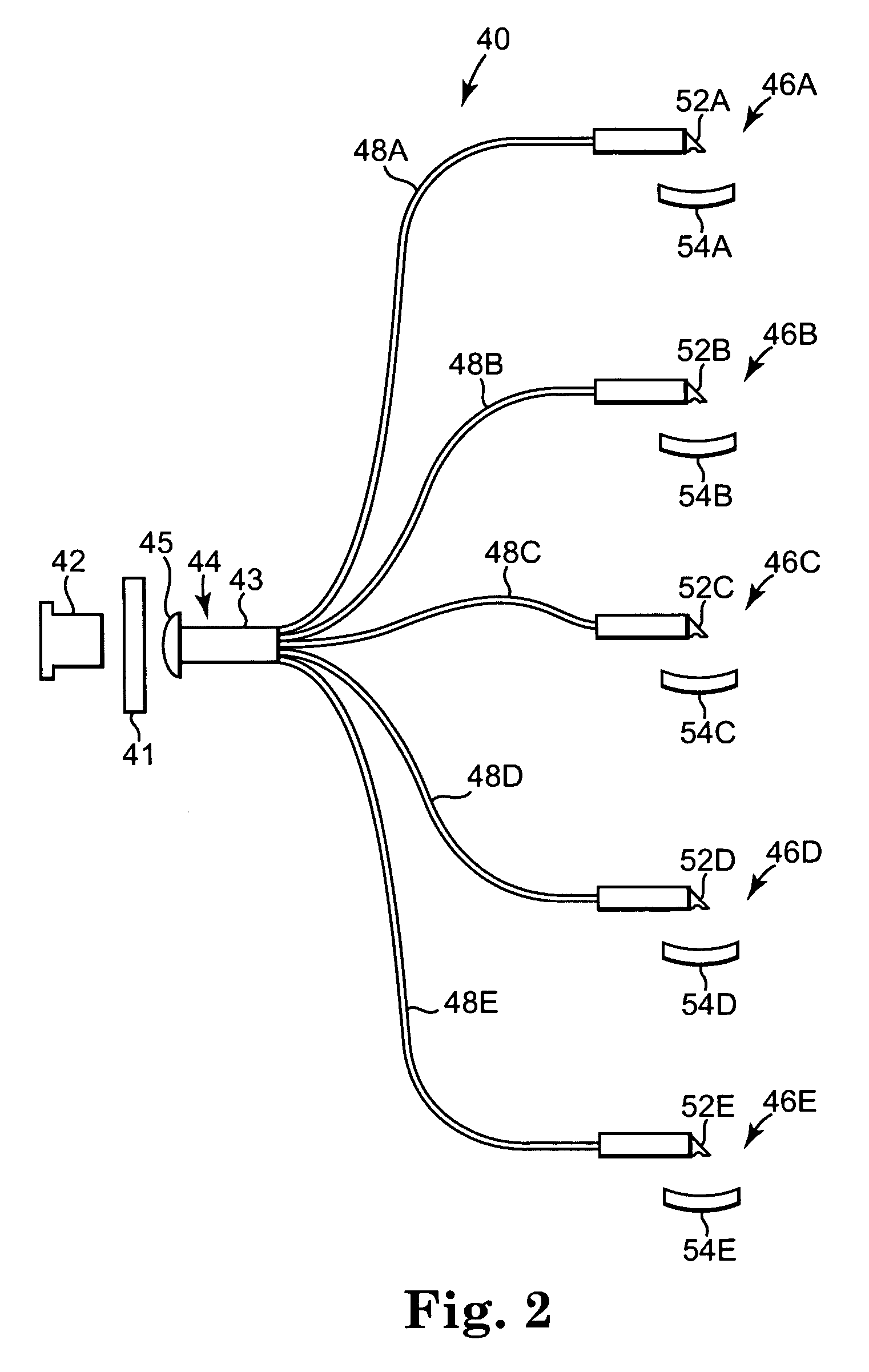

[0026] The present invention is directed to illuminators for dark-field inspection systems, which are commonly used in systems that visually inspect wafers for defects during a particular manufacturing process. An example of a wafer inspection system is shown in FIG. 1.

[0027] A typical wafer inspection system 10 is used in one environment to inspect whole wafers before die have been fabricated on them, but may also be used to inspect patterned whole wafers, die diced from patterned wafers, sawn wafers, broken wafers, wafers of any kind on film frames, die in gel paks, die in waffle paks, MCMs, JEDEC trays, Auer boats, and other wafer and die configurations, whether or not packaged. Hereafter, all of these uses shall be referred to generally as inspection of wafers. System 10 includes a wafer test plate 12, an actuator 14 that moves the wafer to the test plate 12, a wafer alignment device 16 for aligning each and every wafer at the same x, y, and angular location or x, y, z, and ang...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com