Injection port and method of making the same

a technology of injection port and tube, which is applied in the field of injection port and method of making the same, can solve the problems of prone to damage of shrink wrap and potential leakage between the external surface of the plug and the mating surface of the tube,

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] Certain terminology is used in the following description for convenience only and is not limiting. The words “right”, “left”, “lower” and “upper” designate directions in the drawings to which reference is made. The words “inwardly” and “outwardly” refer to directions toward and away from, respectively, the geometric center of the preferred embodiments of the injection port and designated parts thereof. The terminology includes the above-listed words, derivatives thereof and words of similar import. Additionally, the word “a” as used in the specification means “at least one”.

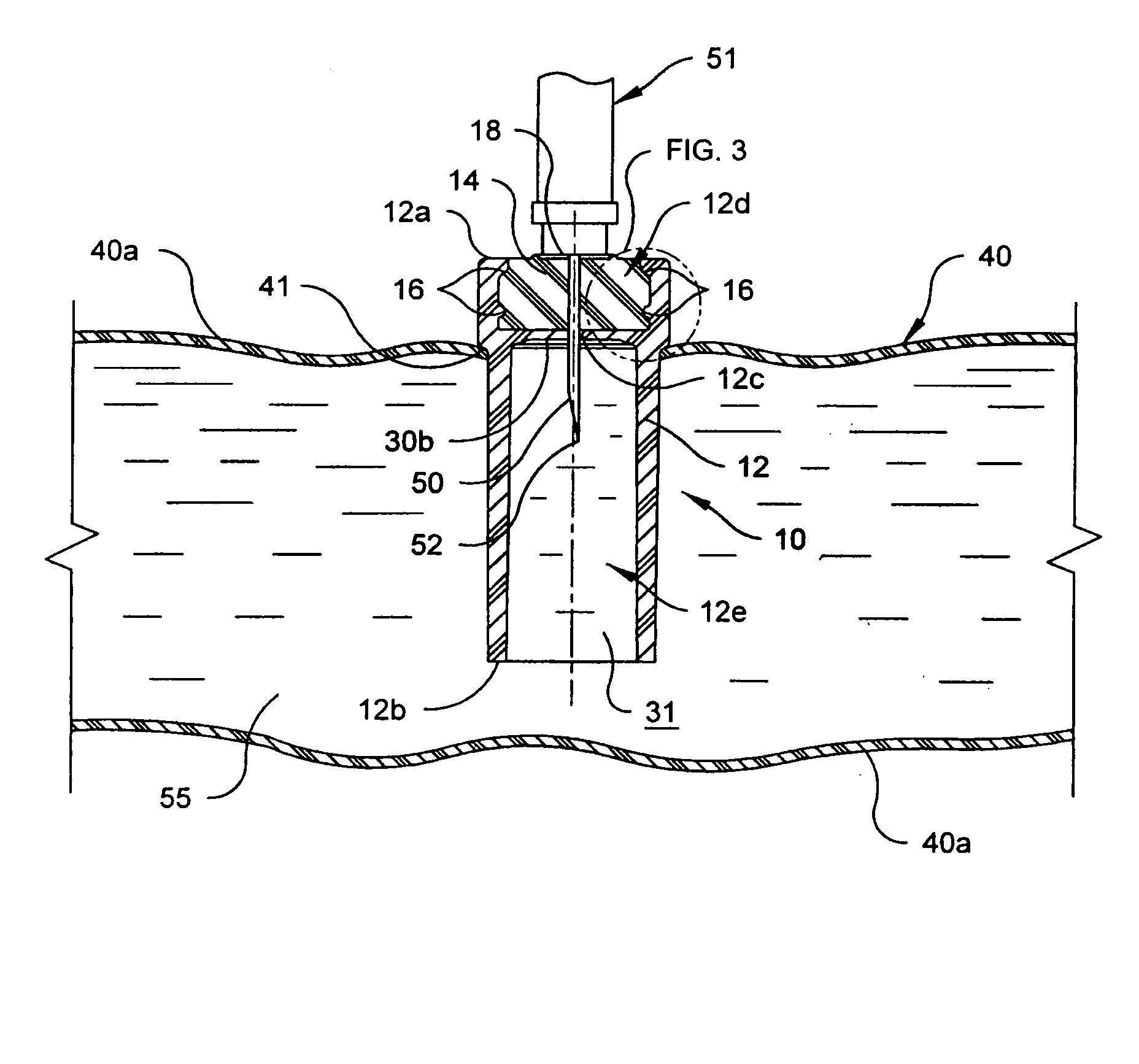

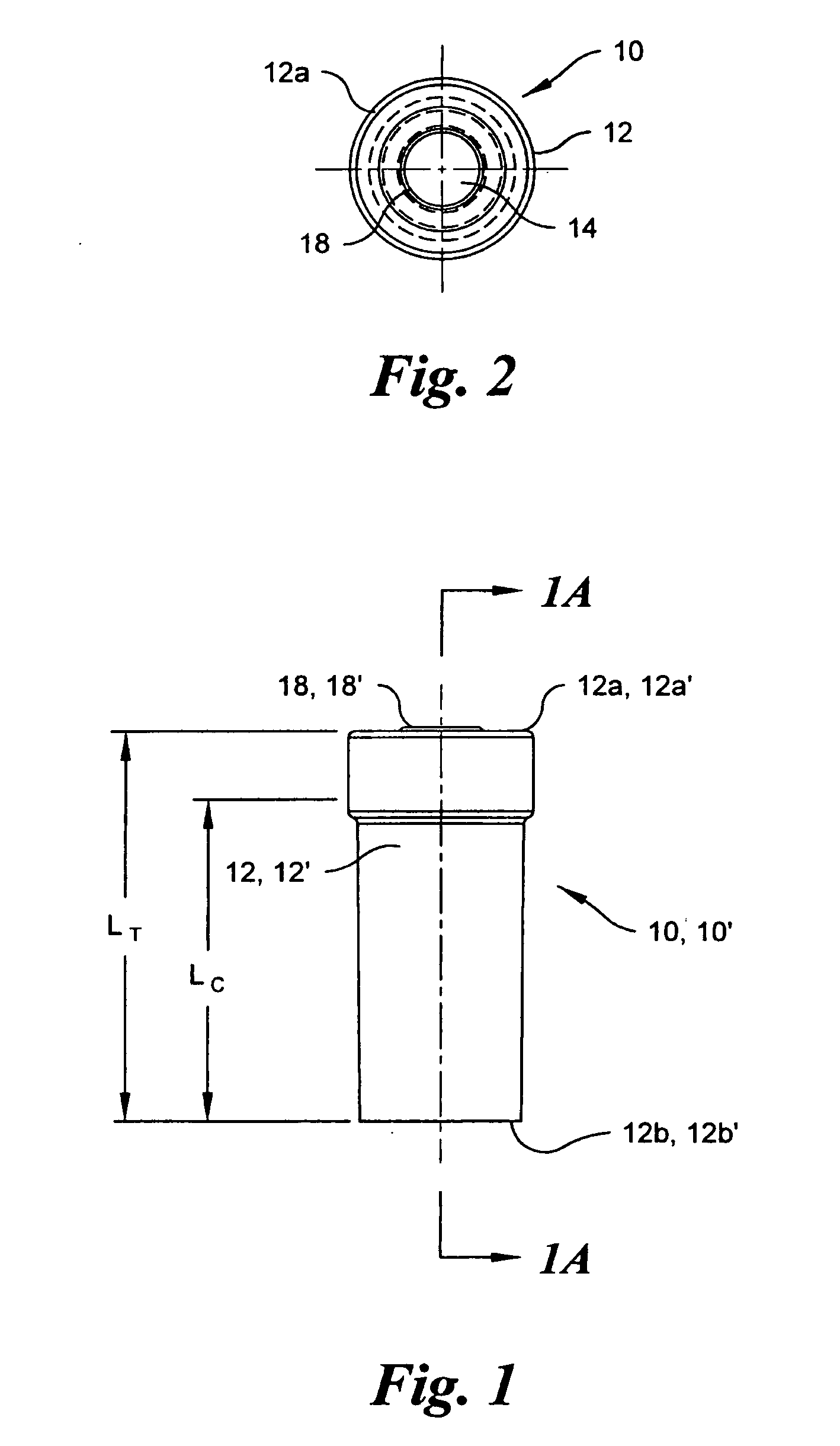

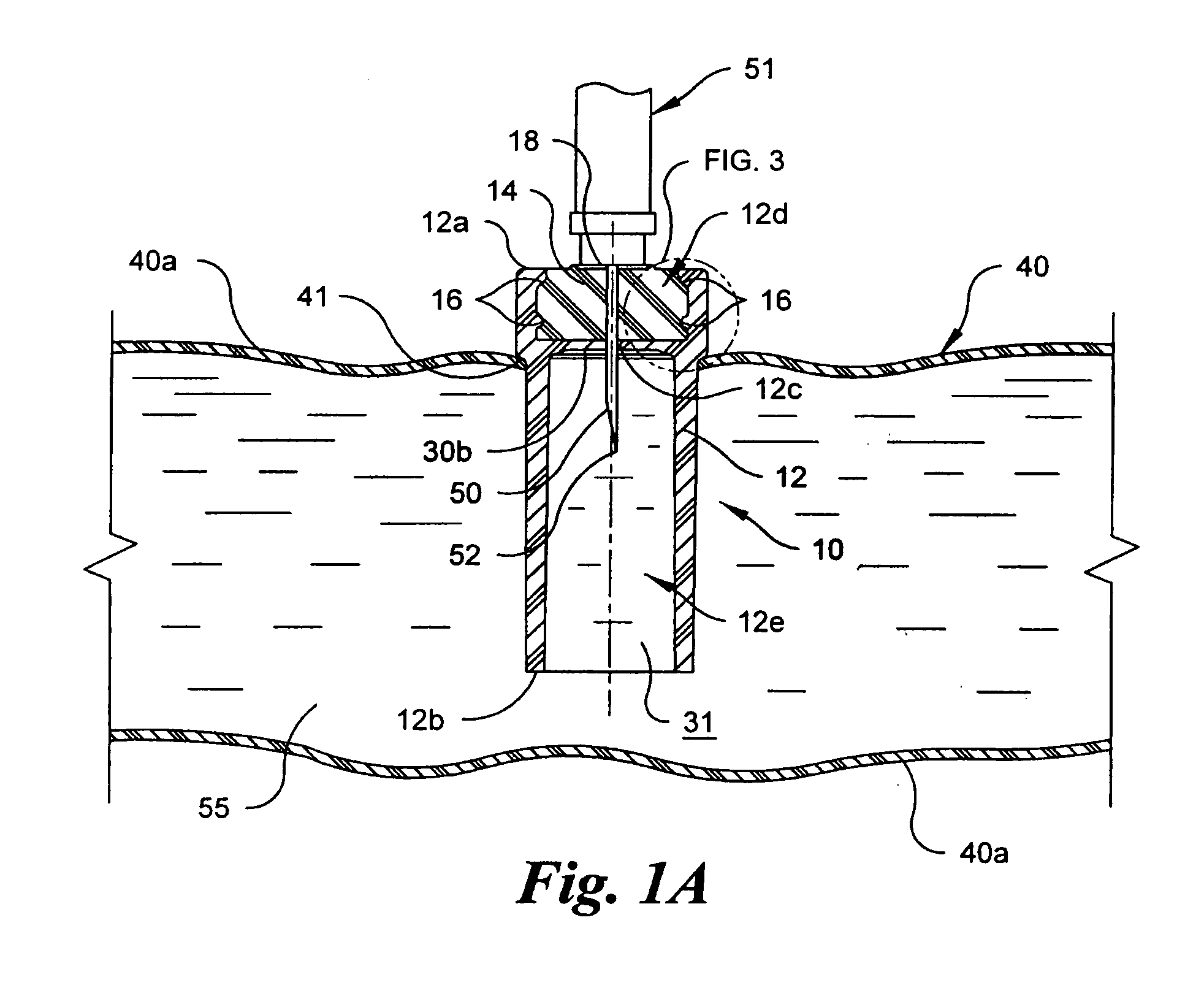

[0019] Referring to FIGS. 1-3, a first preferred embodiment an injection port, generally designated 10, includes a generally hollow tube 12 and a polymeric plug 14. The tube 12 is preferably constructed of an injection molded polyvinyl chloride (“PVC”) material and the plug 14 is preferably constructed of a thermoplastic elastomer (“TPE”) material. The PVC material of the tube 12 is preferred for its form...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thermoplastic elastomer | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| compression set | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com