Air-conditioner and operation control method thereof

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

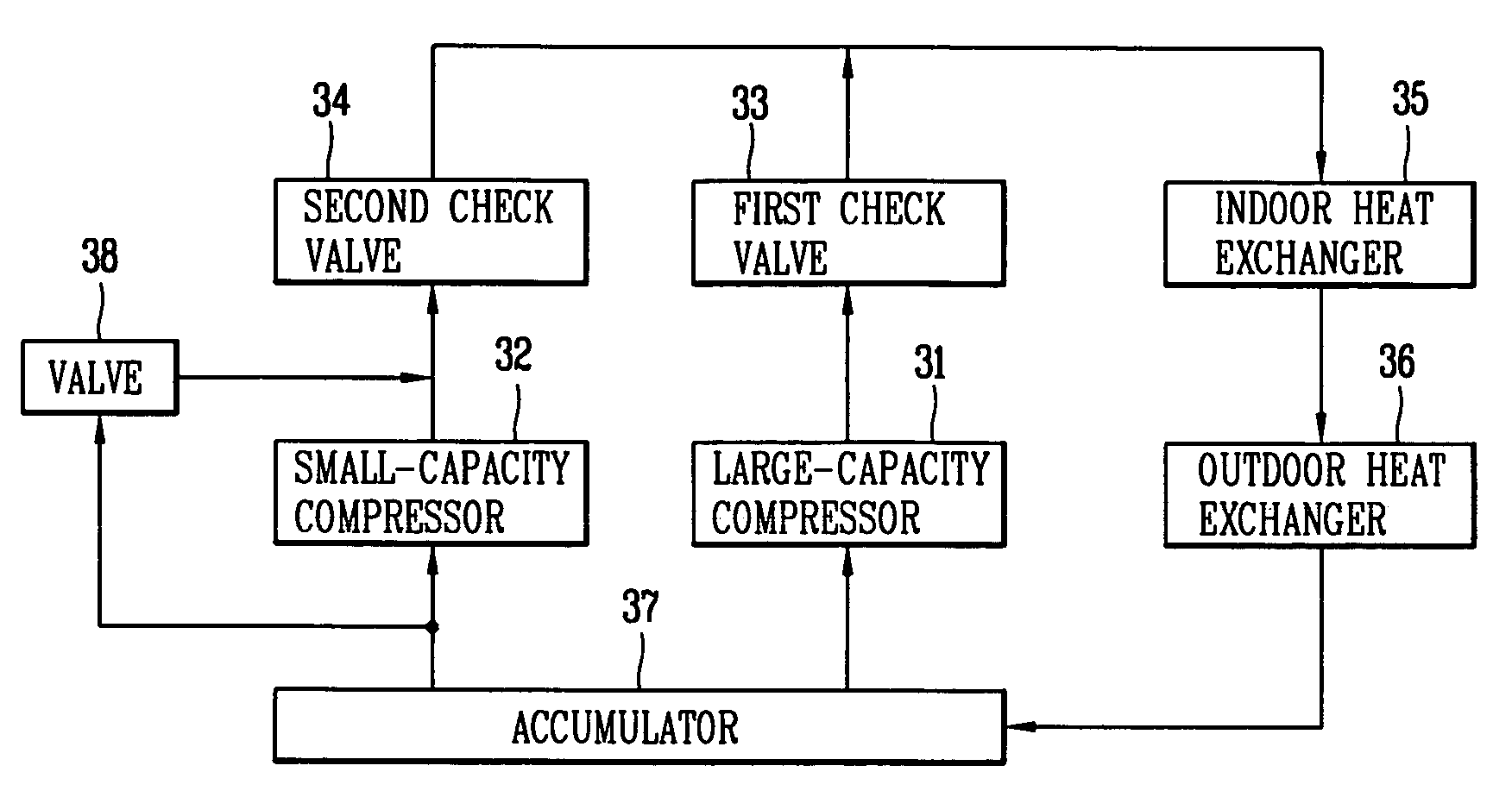

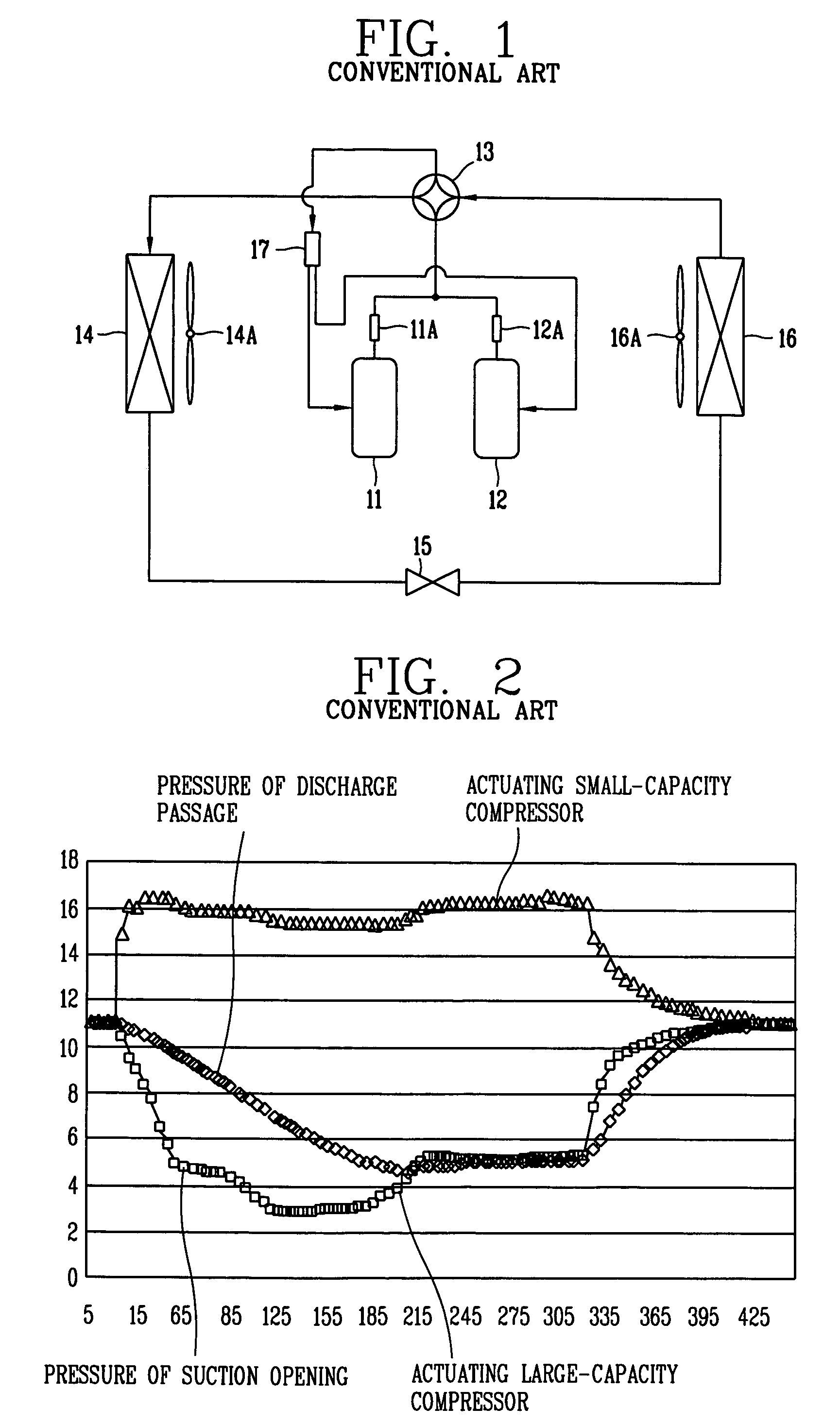

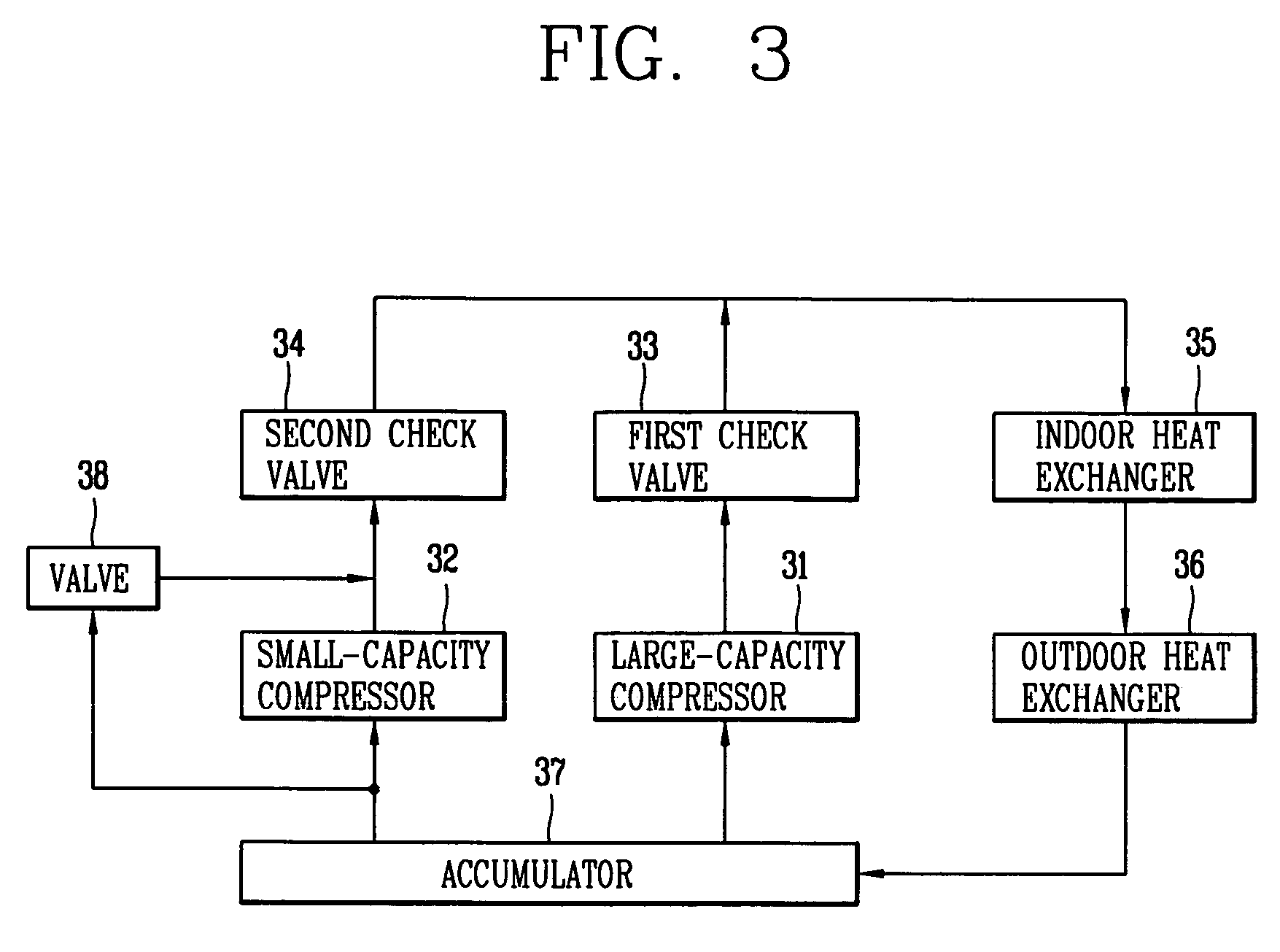

[0025] An air-conditioner capable of enhancing load coping capability by shortening time to make a pressure of a discharge passage of a large-capacity compressor and a pressure of a suction opening of the large-capacity compressor equal before the large-capacity compressor is started for operation while a small-capacity compressor is being operated, and a method for controlling an operation of an air-conditioner in which a small-capacity compressor and a large-capacity compressor are all operated to perform a cooling operation several times repeatedly, and then, when an indoor load is increased while only the small-capacity compressor is operated for cooling a room, a pressure of a discharge passage of the large-capacity compressor and a pressure of a suction opening of the small-capacity compressor are made to be equal and then the large-capacity compressor is started for perform a cooling operation, whereby the cooling operation of the air-conditioner is performed in a high power ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com