Street sweeper with vacuumized dust control

a technology of dust control and street sweeper, which is applied in the direction of suction cleaners, construction, way cleaning, etc., can solve the problems of limited arrangement of rotary brooms between front wheel and rear wheel assembly, inconvenient use of water, and inability to easily find water

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

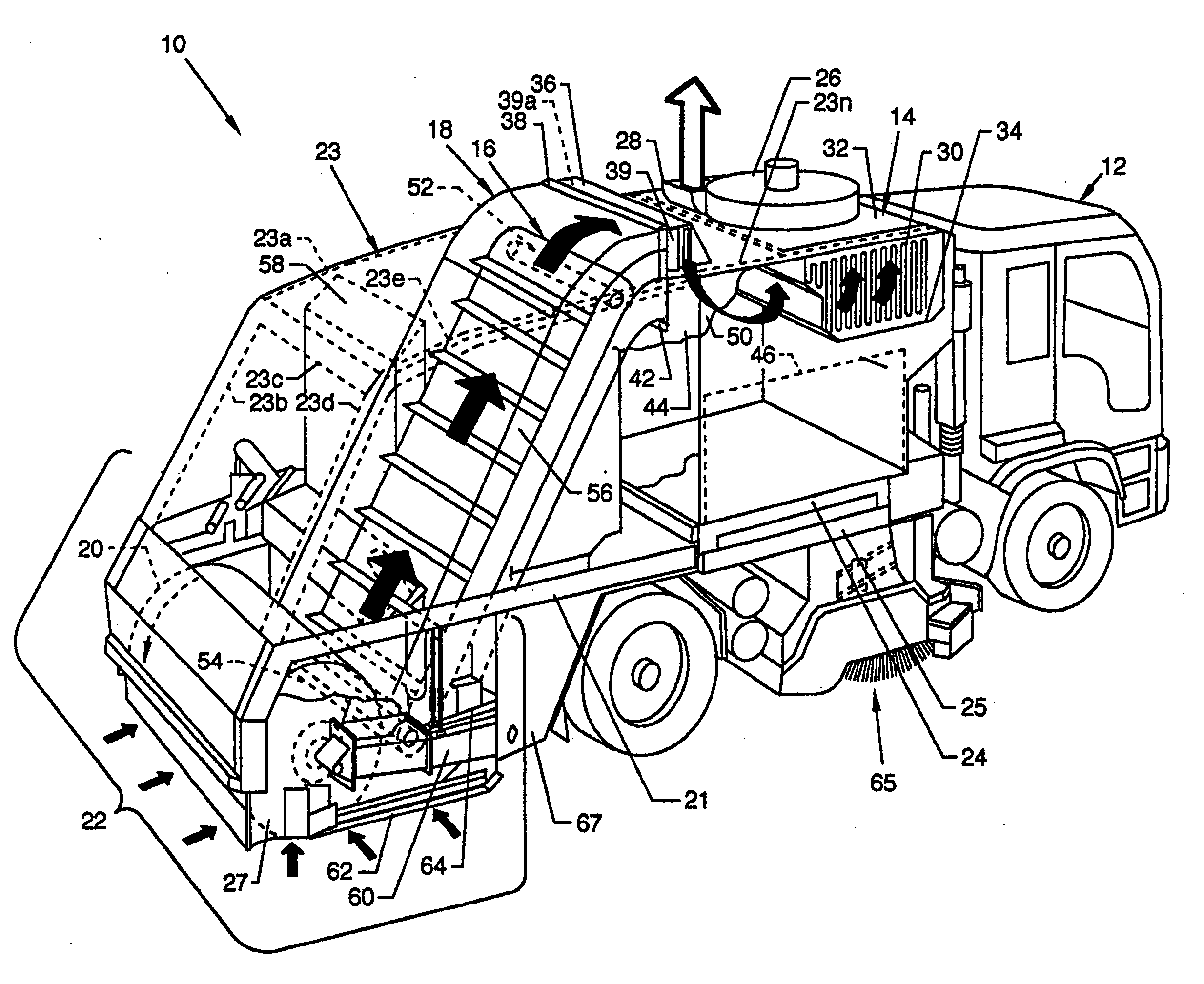

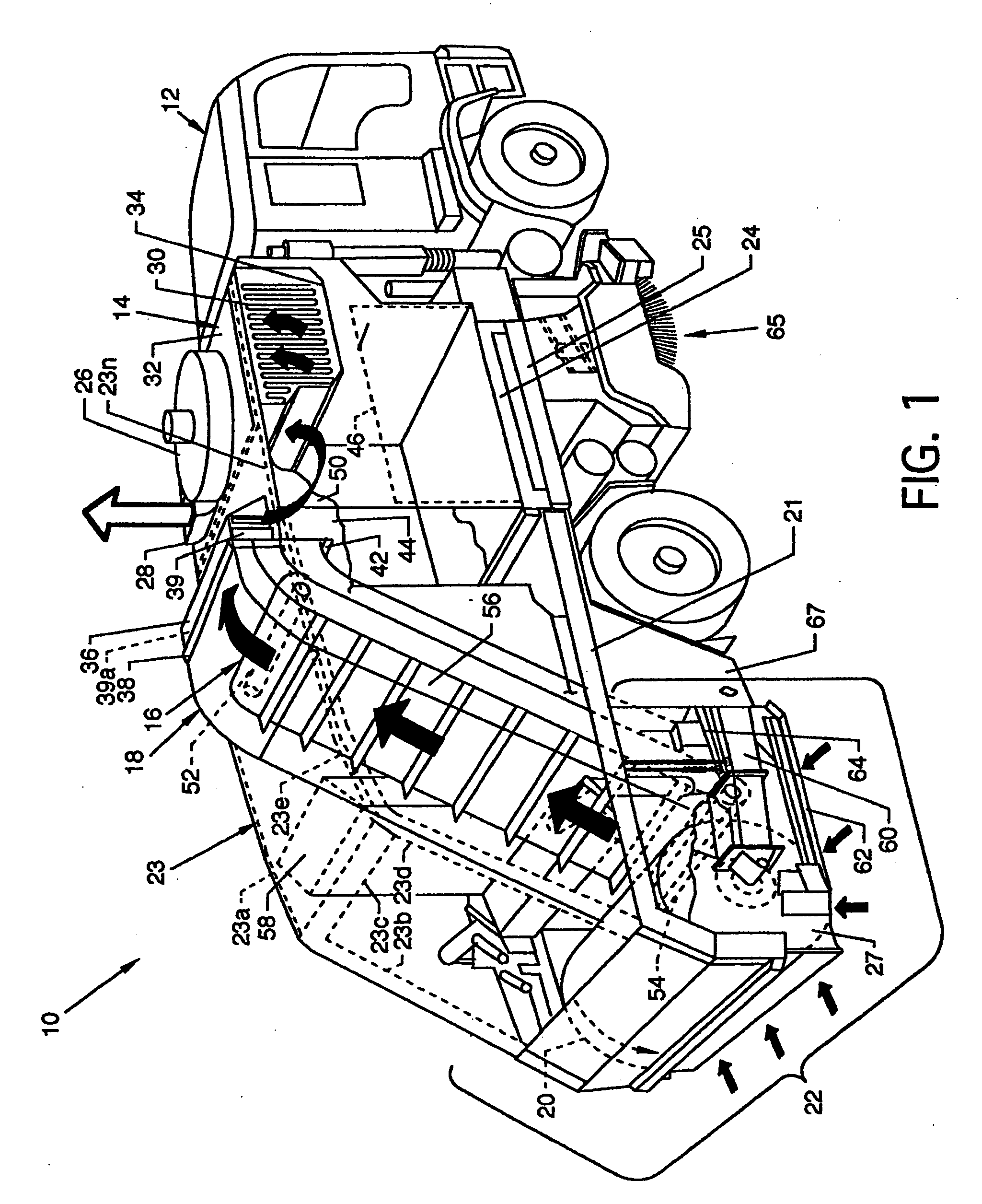

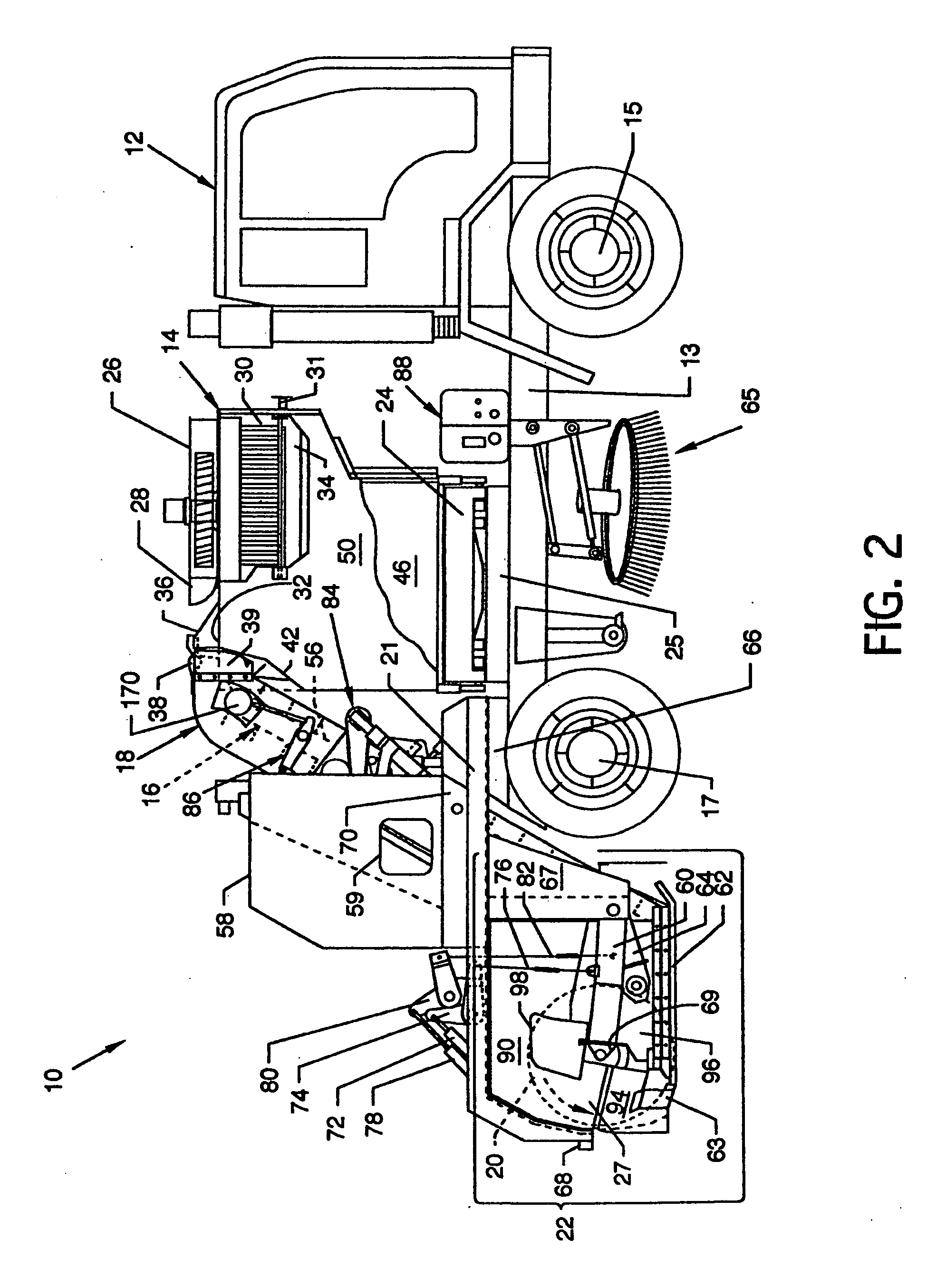

[0029]FIG. 1 illustrates a cutaway overview of the street sweeper 10, the present invention, which has vacuumized duct control. Major and other components complementary to the invention are mounted to and secured to the frame or chassis 13 of a truck 12 or are mounted elsewhere at other locations about the invention. Major illustrated components of the invention include a hopper 14, a conveyor mechanism 16, a conveyor housing 18, a rotary broom 20 and a rotary broom chamber 22 which are arranged and mounted to the chassis 13 of the truck 12 or other frameworks in a position rearward of the street sweeper rear axle 17. Rearwardly extending frameworks 21 and 21a (FIG. 3) mount and secure to the chassis 13 of the truck 12 to accommodate a portion of the components of the invention. A superstructure framework 23 including a plurality of framework members 23a-23n is shown partially and generally in dashed lines extending upwardly and forwardly from the frameworks 21 and 21a to serve as s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com