Apparatus for manufacturing flat-panel display

a technology for flat-panel displays and apparatuses, which is applied in the direction of positioning apparatuses, manufacturing tools, metal-working machine components, etc., can solve the problems of increasing the size of vacuum chambers included in the equipment provided, and the substrate to be processed by the fdp manufacturing apparatus has been recently increased, so as to achieve the effect of easy opening/closing of the upper cover

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

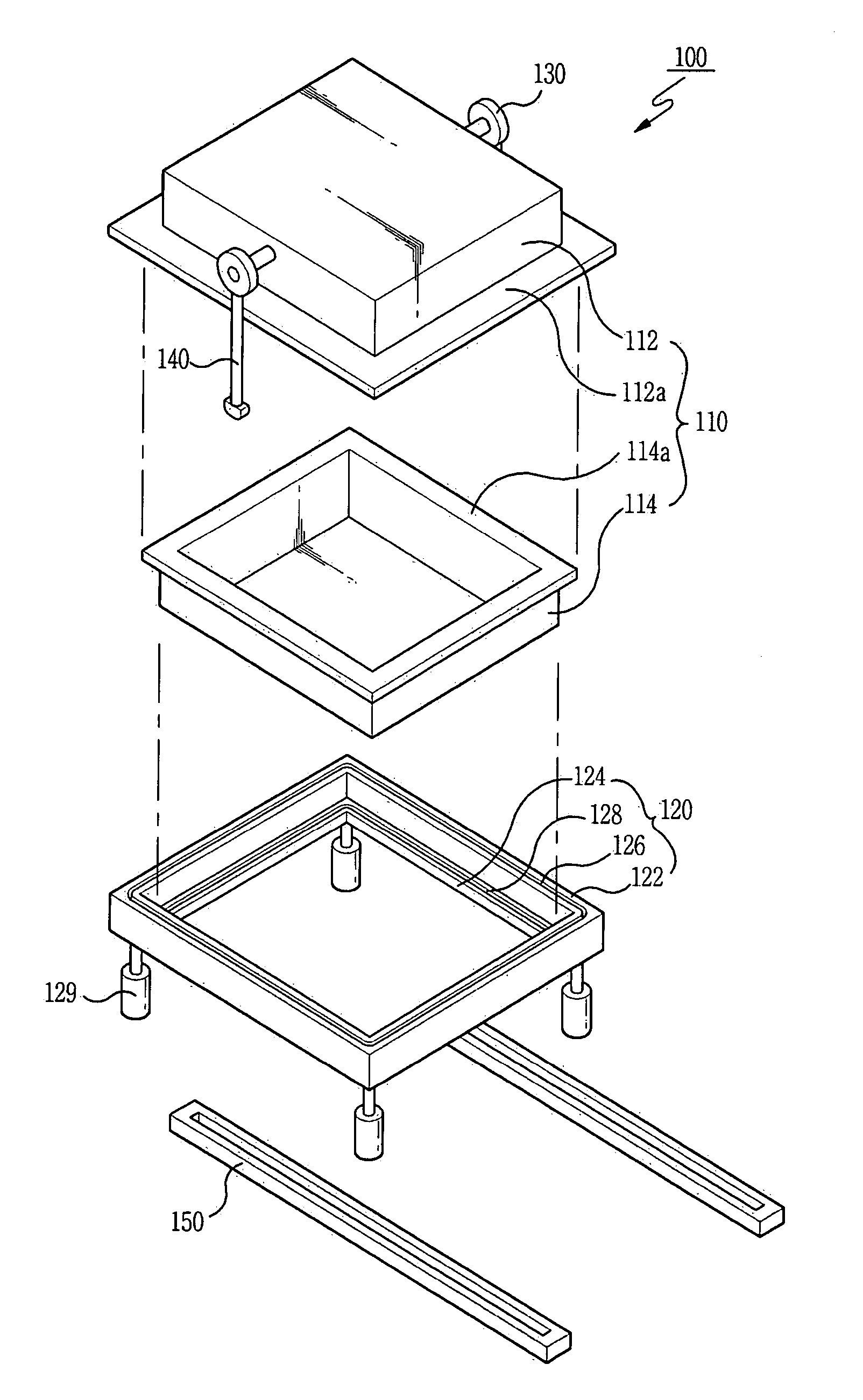

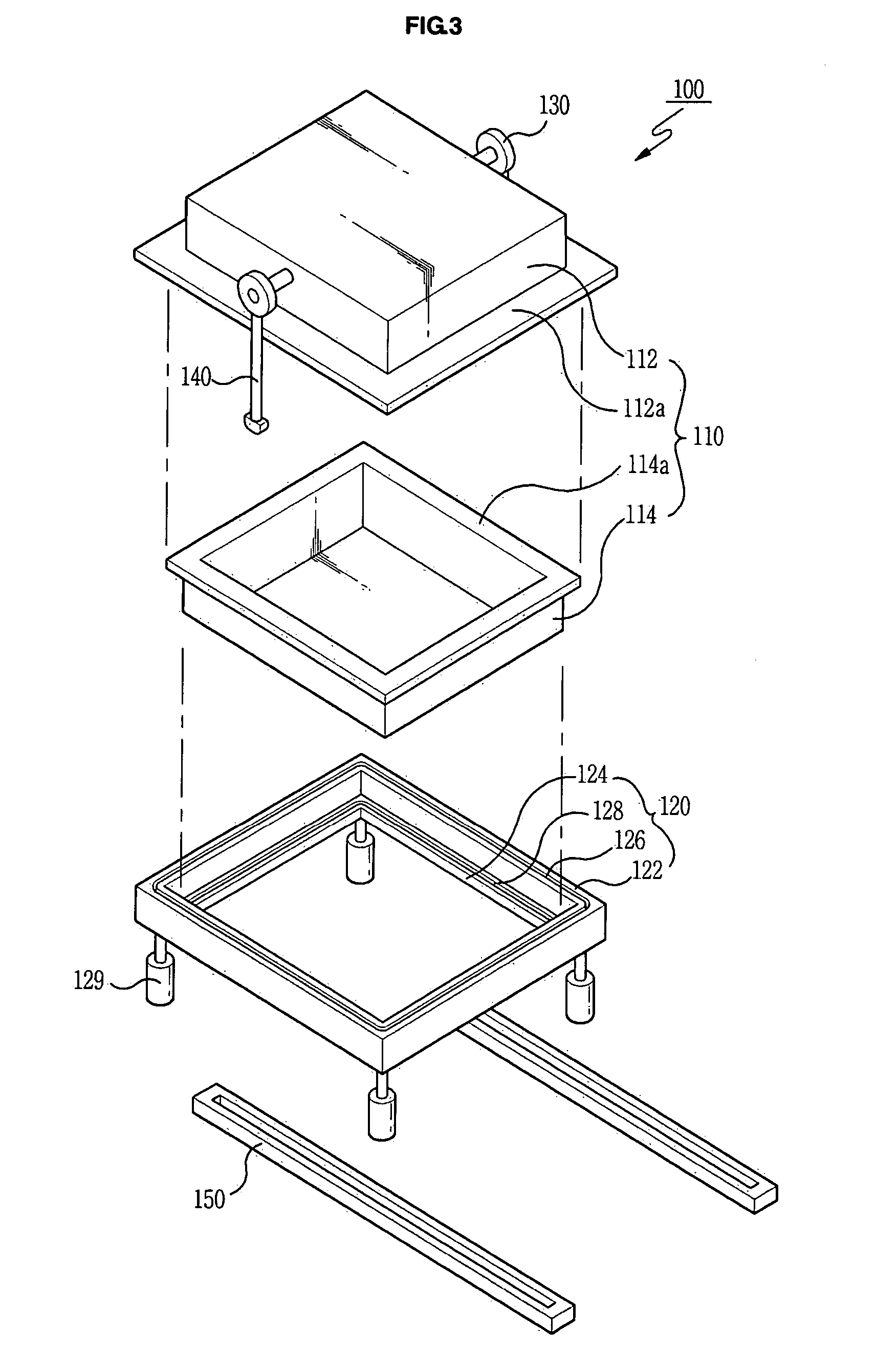

[0038] Referring to FIGS. 3 and 4 illustrating an FPD manufacturing apparatus according to a first embodiment of the present invention, the FPD manufacturing apparatus 100 of the first embodiment comprises: a vacuum chamber 110; sealing means 120; a rotating unit 130; a horizontal drive unit 140; a track unit 150; and processor units 160 and 170.

[0039] The vacuum chamber 110 is designed to establish a vacuum atmosphere therein. In the present embodiment, the vacuum chamber 110 is divided into a chamber body 114 and an upper cover 112. The chamber body 114 forms a lower chamber section of the vacuum chamber 110, and is constituted by a bottom wall and a sidewall vertically extending upward from the periphery of the bottom wall. The upper cover 112 forms an upper chamber section of the vacuum chamber 110, and is constituted by a top wall and a sidewall vertically extending downward from the periphery of the top wall. As the upper cover 112 is coupled with the chamber body 114, the va...

second embodiment

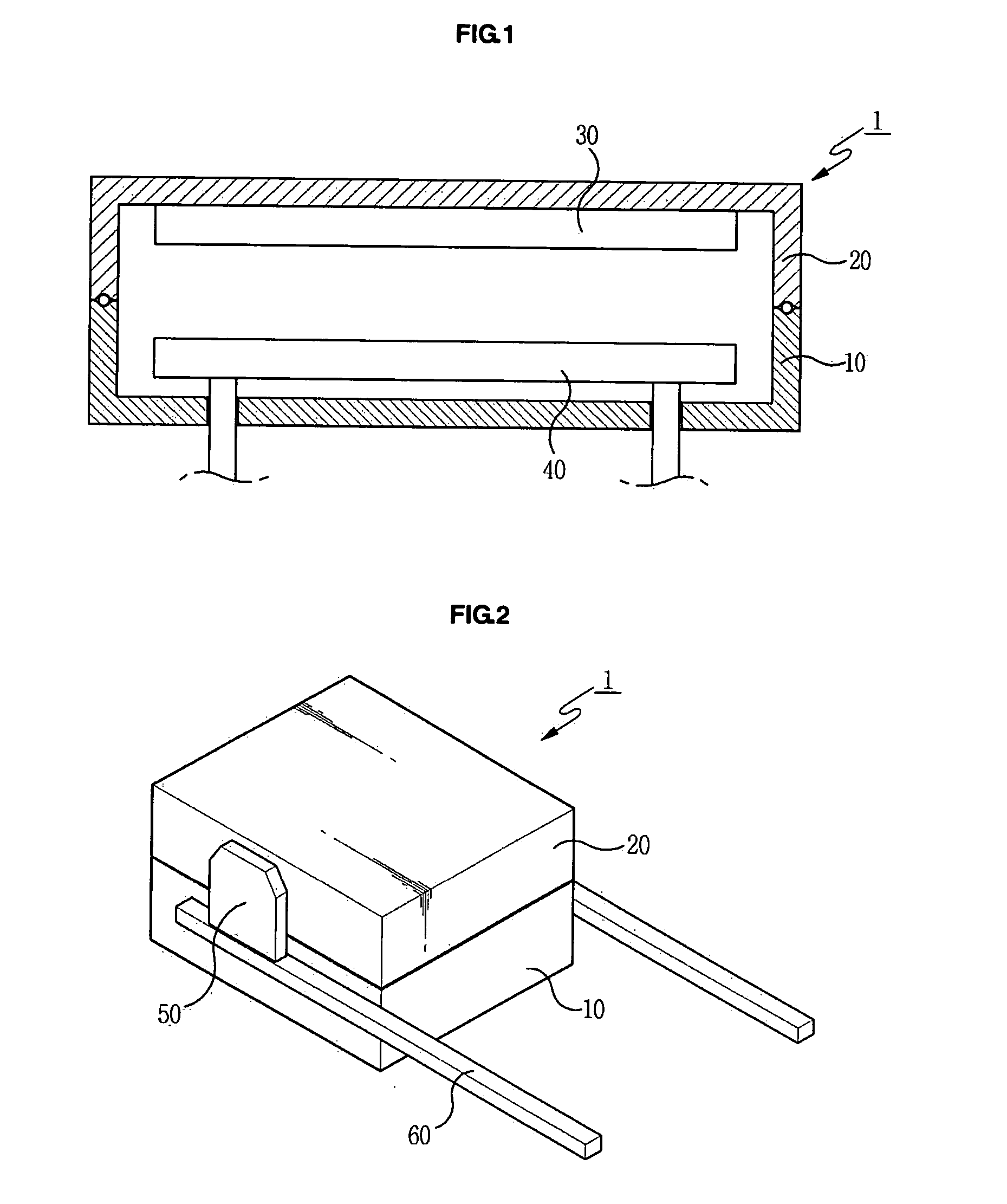

[0061] An FPD manufacturing apparatus according to the present embodiment comprises: a vacuum chamber; sealing means; and processor units. In the same manner as the first embodiment, the vacuum chamber includes a chamber body and an upper cover, and the sealing means is configured to seal rims of the chamber body and the upper cover. The processor units are arranged in the vacuum chamber to perform a desired process for a substrate. The configurations and functions of the vacuum chamber, sealing means, and processor units are identical to those of the first embodiment, and accordingly, no further description will be given.

[0062] Differently from the first embodiment, the FPD manufacturing apparatus of the present embodiment is not provided with the rotating units, horizontal movement units, and track units. The upper cover of the present embodiment is spaced apart from the chamber body by a predetermined distance by use of separate supporting members. The supporting members are cou...

third embodiment

[0065] Referring to FIG. 7 illustrating an FPD manufacturing apparatus 200 according to the third embodiment of the present embodiment, the FPD manufacturing apparatus 200 comprises a lower chamber 210; an upper chamber 220; a horizontal drive unit 230; and a rotating unit 240. The lower and upper chambers 210 and 220 have downwardly inclined coupling surfaces, which extend in a movement direction of the upper chamber 220. That is, the coupling surfaces of both the lower and upper chambers 210 and 220 are inclined in a specific direction, i.e. are inclined downwardly in the movement direction of the upper chamber 220, rather than being horizontally parallel to the ground surface. With the inclined coupling surfaces of the lower and upper chambers 210 and 220, the upper chamber 220 can be easily separated from the lower chamber 210 as it horizontally slides on the lower chamber 210 without friction therebetween. This eliminates the necessity of lifting the upper chamber 220 by a pred...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com