Gas turbine airfoil film cooling hole

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

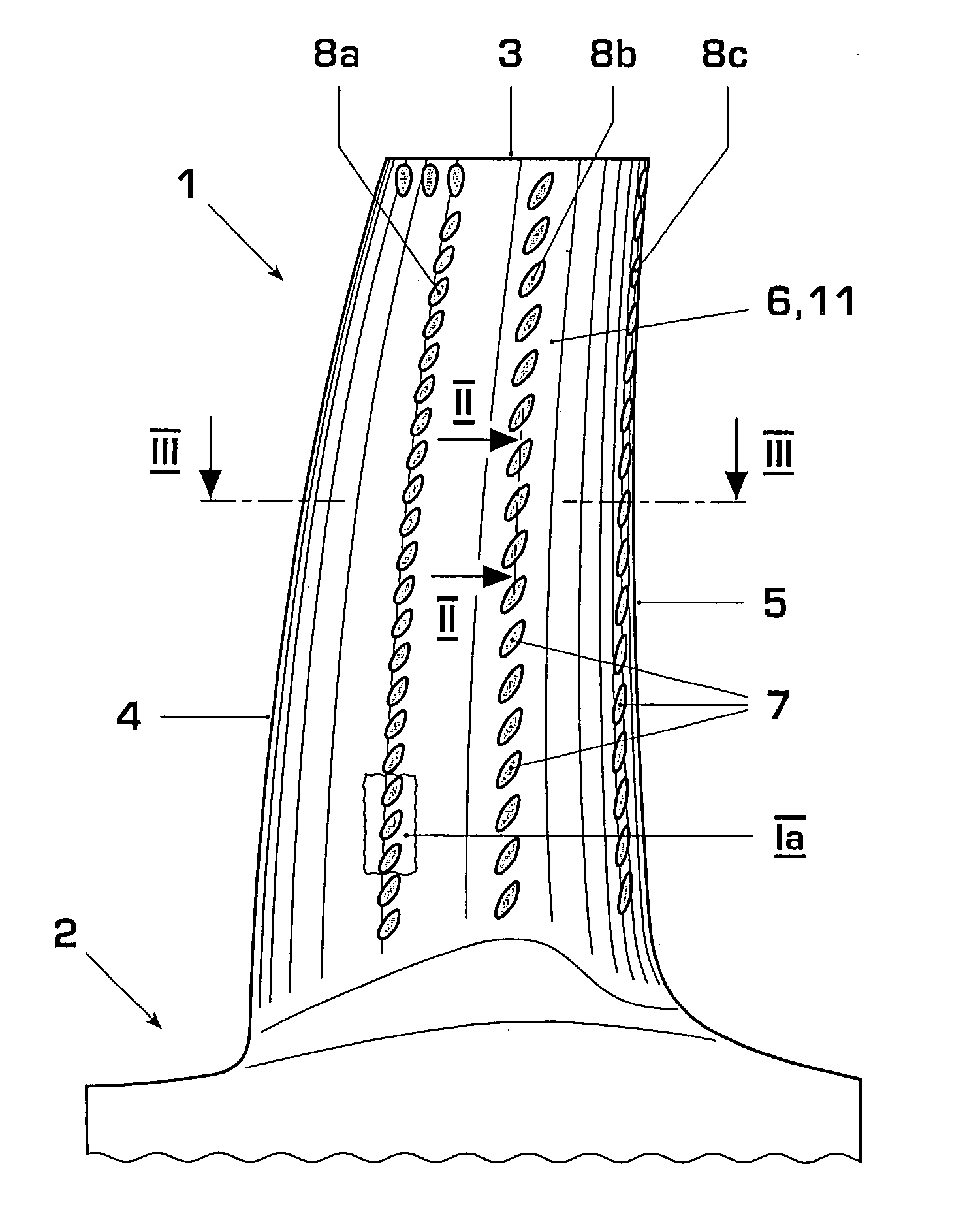

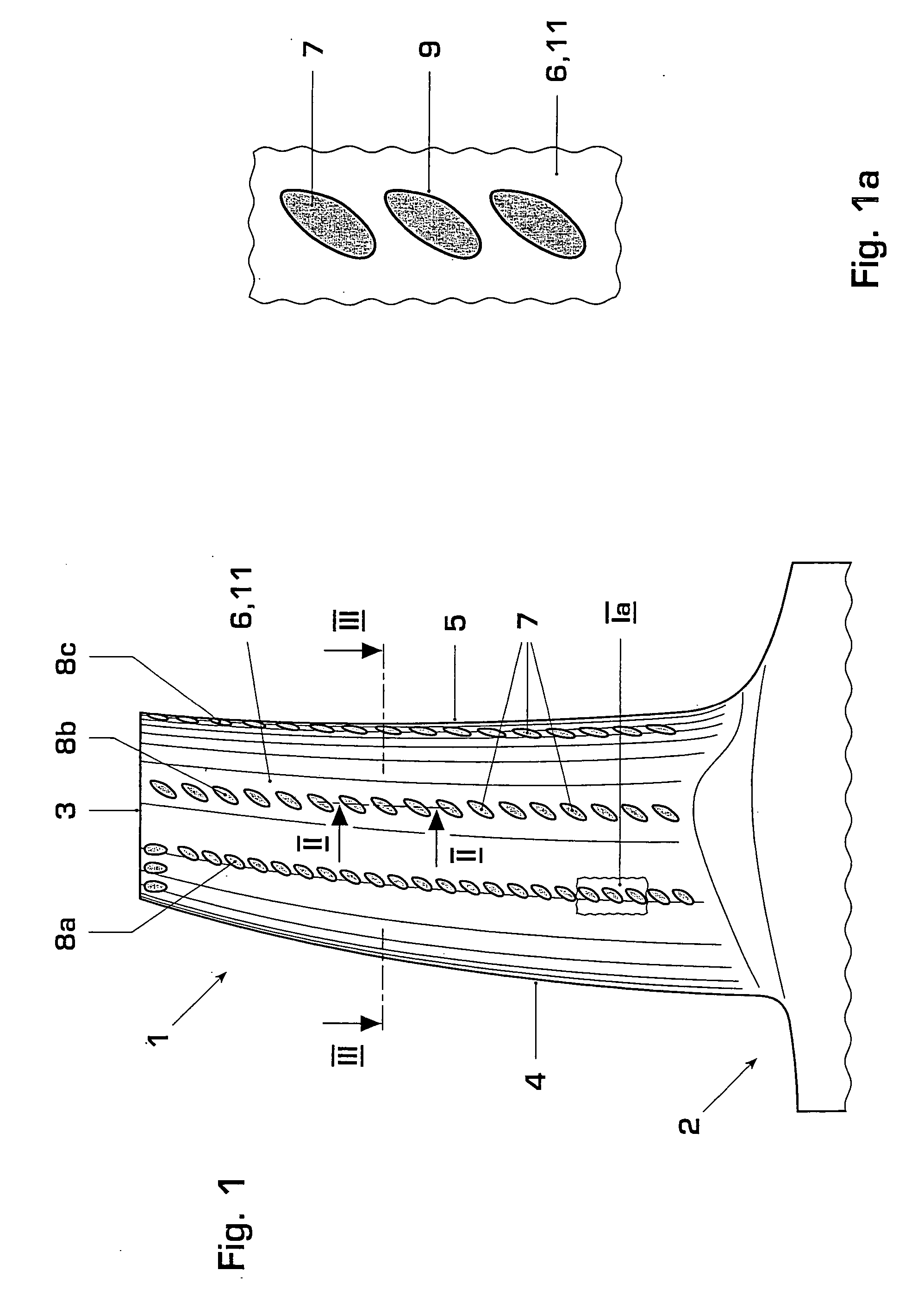

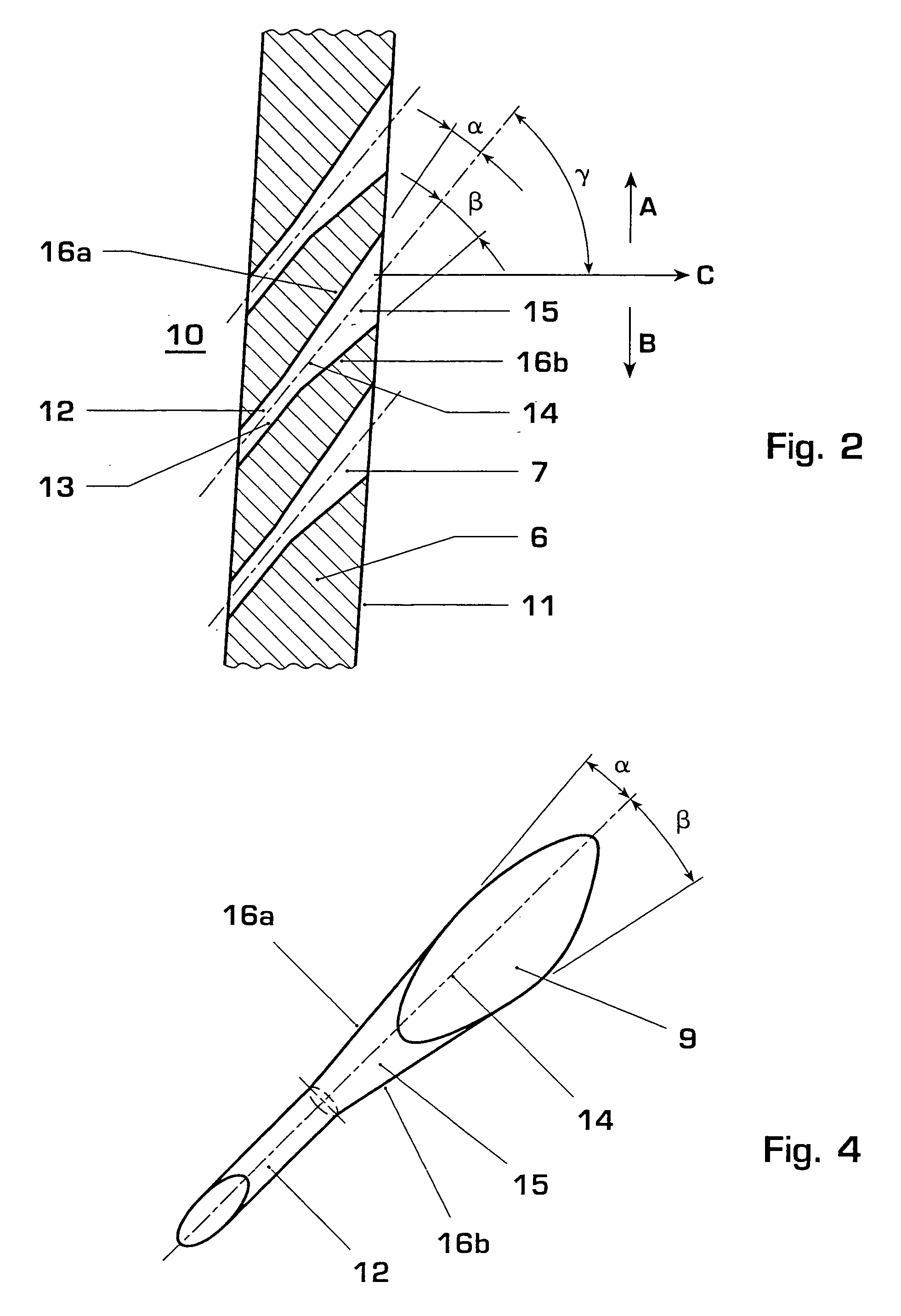

[0023]FIG. 1 shows a typical airfoil 1 of a gas turbine extending from a root 2 to a tip 3 and frown a leading edge 4 to a trailing edge 5. The figure shows the airfoil from its suction side 6. Several film cooling holes 7 are arranged In radially extending rows 8a, 8b, and 8c on the suction side 6. The film cooling holes 7 are realized with diffused sidewalls resulting in an irregularly shaped exit port 9 as shown in an enlarged view in FIG. 1a.

[0024] The film cooling holes extend from internal cooling passages within the airfoil 1 through the suction sidewall 6 to its outer surface 11. They provide convective cooling of the sidewall from within as well as film cooling of the sidewall outer surface 11.

[0025] In one embodiment of the invention the film cooling holes with diffused sidewalls are arranged in one or more radially extending rows on the suction side of the airfoil.

[0026] The number of rows of film cooling holes and their position is determined based on the metal temper...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com