Vegetable harvester and method

a harvester and vegetable technology, applied in the field of self-propelled harvesters, can solve the problems of affecting the harvesting effect, so as to achieve the effect of reducing the ground pressure, increasing the tension on the spring, and being easy to us

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

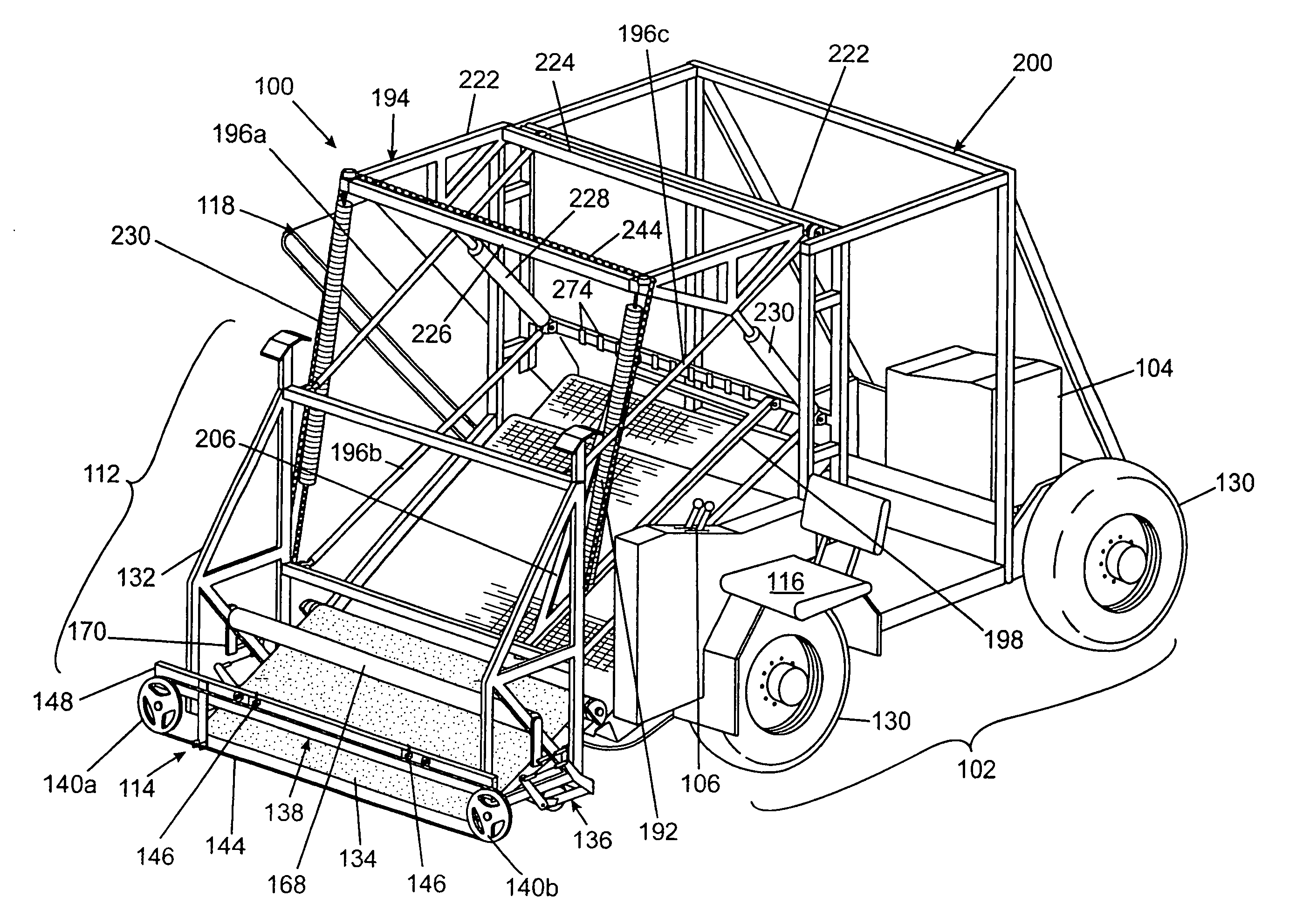

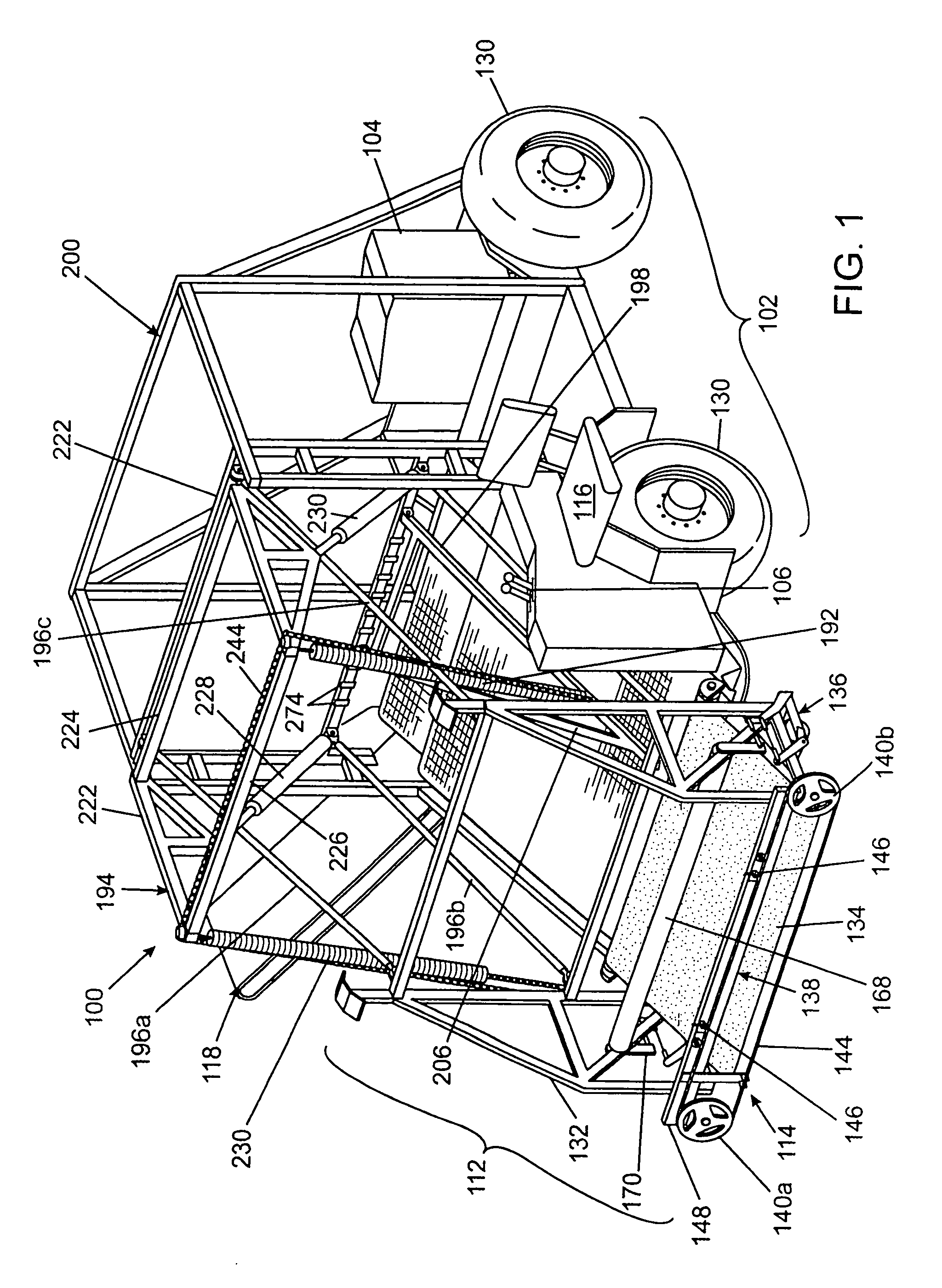

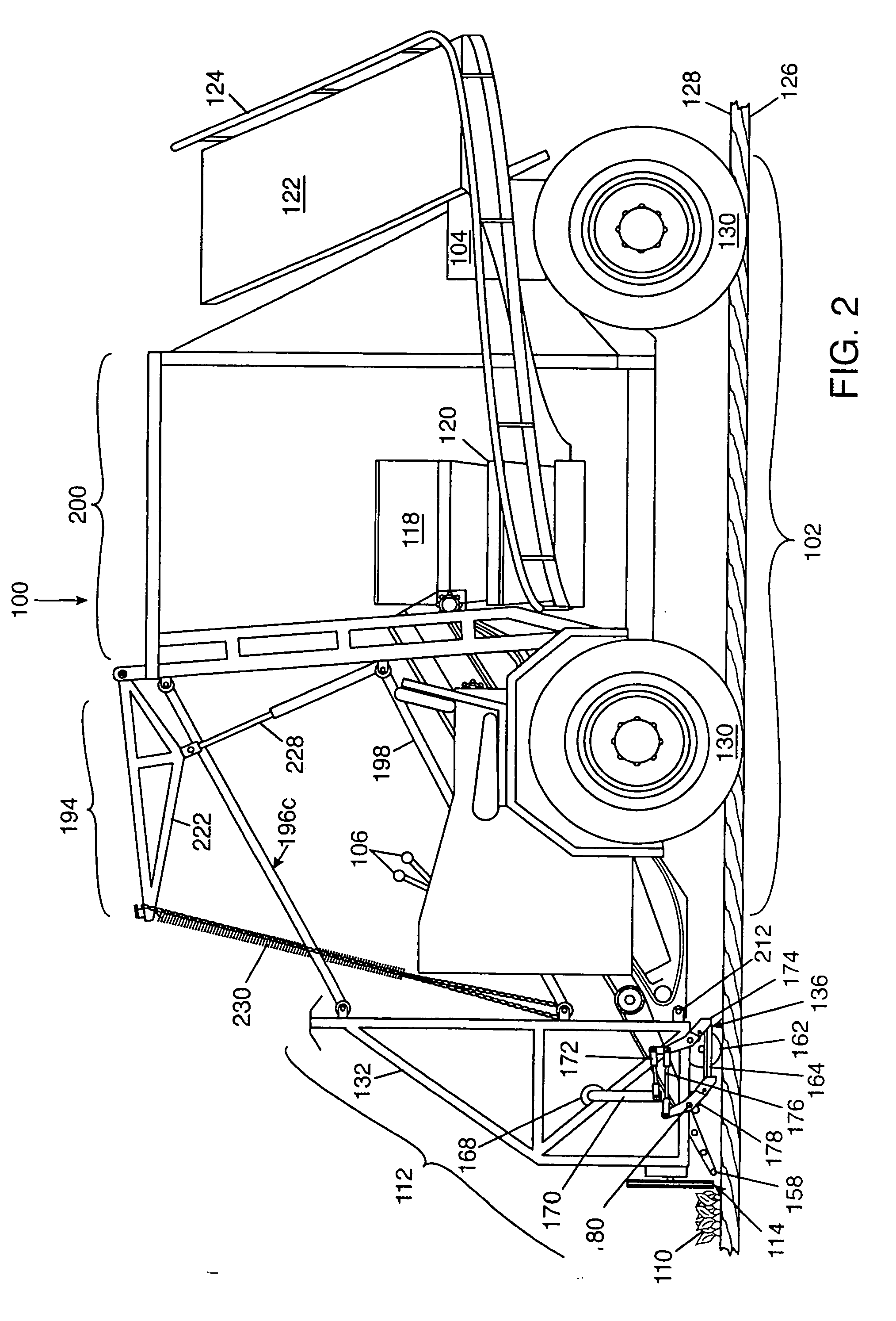

[0020] Although the harvester of the invention may be useful for harvesting a variety of kinds of produce, it is particularly suited for harvesting baby greens. The harvester generally comprises a chassis with wheels that travel in the furrows between raised beds, a floating header, that includes a cutting assembly, coupled to the chassis, and a series of belts for collecting and sorting the cut baby greens. The harvester is designed to efficiently cut the vegetables to be harvested, yet also to be lightweight, simple, dependable, inexpensive, and maneuverable.

[0021] In general, the invention comprises a floating header, including a cutting assembly, that rides on the top surface of a raised bed and that is articulated so that the floating header can move independently of the chassis to follow the contours of the top of the raised bed in order to cut the baby greens to be harvested at a relatively uniform height above the surface of a raised bed on which the greens are grown. The i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com