Trestle with postpositive drive and method of installing and adjusting

A trestle bridge and main bridge technology, applied to bridges, bridge forms, shaft equipment, etc., can solve the problems of slow construction progress, low construction efficiency, waste of materials, etc., and achieve the effects of ensuring safety, reliable connection, and stable support

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

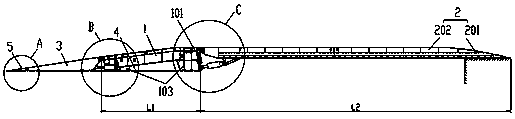

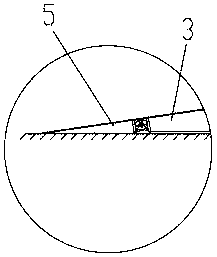

[0126] The driving rear trestle of this embodiment is applied in the process of tunnel construction.

[0127] drive rear trestles, such as figure 1 , figure 2 , image 3 and Figure 4 As shown, it includes the main bridge 1 arranged on the support surface 4, the angle between the bridge deck of the main bridge 1 and the support surface is an acute angle, and the front end and the rear end of the main bridge 1 are connected to the front approach bridge 2 and the rear bridge respectively. Approach bridge 3, described front approach bridge 2 comprises inclined section 201 and horizontal section 202, and the deck of described inclined section 201 forms an acute angle with horizontal plane, and described horizontal section 202 is connected with main bridge 1, and the length of described front approach bridge 2 is longer than main bridge The length of bridge 1. The supporting surface 4 is a lined concrete surface, that is, the filling surface of the inverted arch in the tunnel....

Embodiment 2

[0138] The driving rear trestle of the present embodiment is roughly the same as embodiment 1, and the trestle foundation of embodiment 1 is provided with walking device, as Figure 5 , Figure 6 , Figure 7 , Figure 8 , Figure 9 , Figure 10 and Figure 28 As shown, the left and right ends of the main bridge 1 are provided with a lifting mechanism 603, and the lower part of the lifting mechanism 603 is provided with a running device 7. The running device 7 includes a track 701 and a supporting running mechanism 71. Connected with the main bridge 1, the traveling device 7 also includes a telescopic mechanism 702 connected at one end to the traveling mechanism 71, and the other end of the telescopic mechanism 702 is connected with a fixing device 8 installed on the track, and the fixing device 8 is detachable connected to track 701. The traveling mechanism 71 can be driven to move by stretching or shortening the telescopic mechanism 702. When the fixing device 8 is sepa...

Embodiment 3

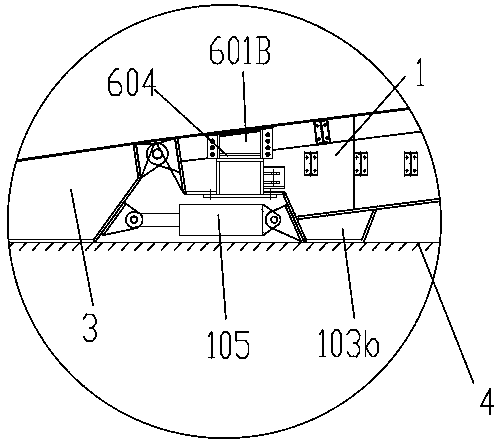

[0146] The drive rear trestle of the present embodiment is roughly the same as embodiment 1, and the trestle foundation of embodiment 1 is provided with traverse device 6, as Figure 5 , Figure 11 and Figure 12 As shown, the traversing device 6 is installed on the main bridge 1, and the traversing device 6 includes a connecting rod 601 arranged under the main bridge 1, and a sliding connection between the connecting rod 601 and the main bridge 1, the connection A translation mechanism 602 is connected between the rod 601 and the main bridge 1 , one end of the translation mechanism 602 is connected to the main bridge 1 , and the other end is connected to the connecting rod 601 , and the two ends of the connecting rod 601 are respectively connected to a lifting mechanism 603 .

[0147] As one of the implementation manners, the lifting mechanism 603 is a vertically arranged oil cylinder, the cylinder barrel of the oil cylinder is connected with the connecting rod 601 , and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com