Automobile form harvester chasis

A harvester and chassis technology, which is applied in the field of agricultural machinery, can solve problems such as strong ground pressure, unfavorable surface protection of cultivated land, and limit the speed of the vehicle to not be too fast, so as to reduce the degree of bumping, safe and reliable braking performance, and reduce the pressure on the ground. Effect

Inactive Publication Date: 2008-06-04

于政道

View PDF0 Cites 2 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

However, after being transplanted to harvesting machinery, some disadvantages appear, mainly including: most of the weight of the vehicle body is carried by the driving wheel, and the pressure on the ground is too large, which is not conducive to the protection of the cultivated land surface; Traction, so the ability to grip the ground is no longer emphasized; during the transfer operation, because the steering wheel has no brakes, the speed limit cannot be too fast, which affects the transfer speed and braking safety performance of the harvester

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

[0013] ZL-275 type harvester has adopted a specific embodiment of above-mentioned invention. This type of harvester is equipped with a 240-horsepower engine, and the moving speed can reach 90km / h. The pressure on the ground is half that of a general self-propelled harvester of the same weight. Its braking performance and other safety performance are equivalent to those of a truck with the same power. .

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

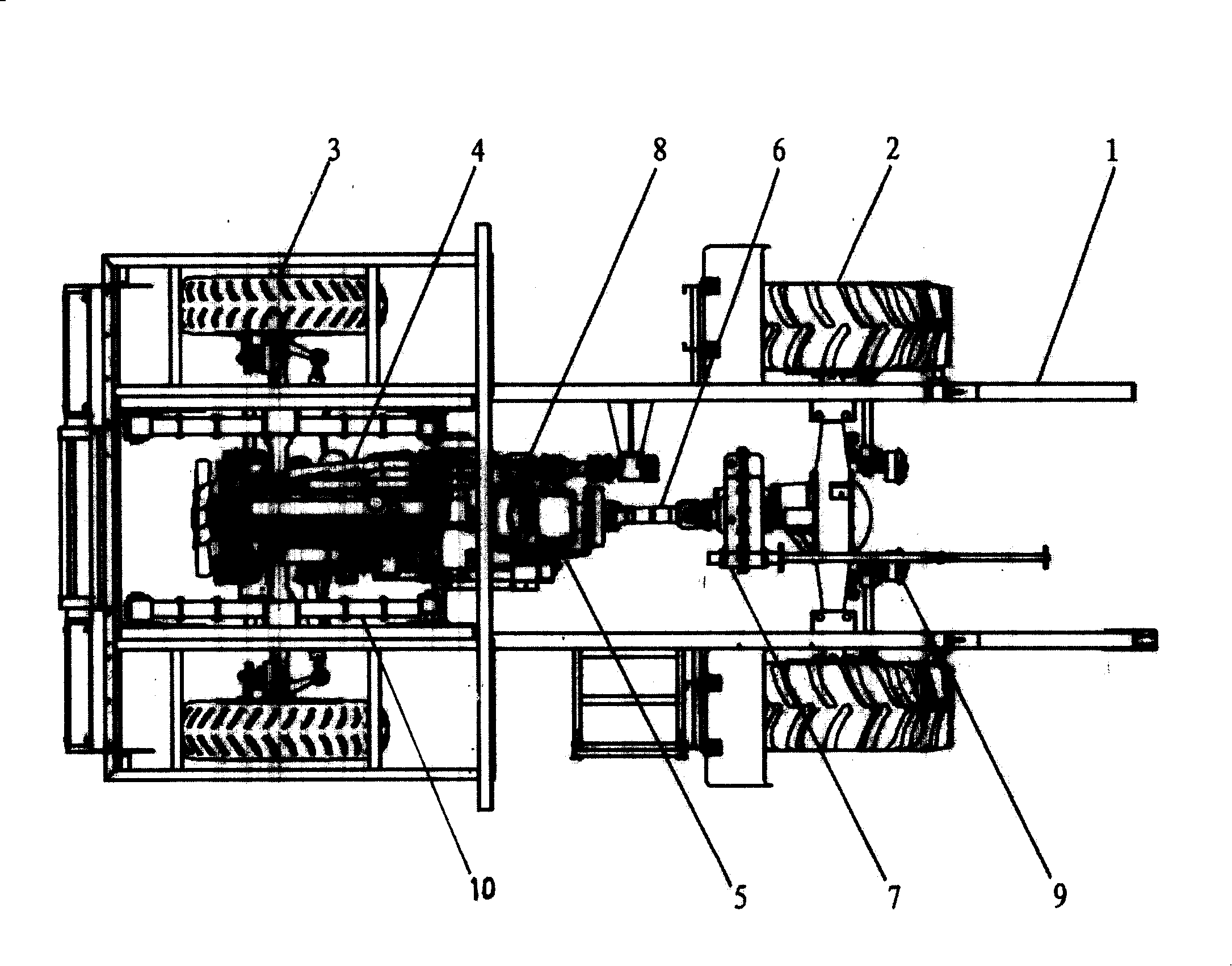

The invention relates to a cropper chassis of a type similar to the type of an automobile, and is an agricultural machine. A majority of current cropper chassis have machines weighing on a driving wheel and an oversized pressure to the ground, thus being beneficial to the protection of the surface of the arable land; when a shift-region operation is carried out, as a directive wheel is not provided with a braking, the shift-region speed is limited, thus reducing the safety property of the braking. The invention provides a cropper chassis a type similar to the type of an automobile, and includes a machine frame, a driving axle, a directive axle, an engine, a gear-box, a transmission shaft, a reverse gear-box, a force obtaining device, a four-wheel braking system, and a damping flat spring. The whole chassis is a rear steering type, therefore the total weight is distributed equally to four tyres, and the pressure to the ground is greatly lowered; meanwhile, the adoption of the braking of the four wheels and the damping flat spring arranged on the directive axle assure safe and fast trans-regional work of the cropper.

Description

technical field [0001] The invention relates to a harvester chassis similar to that of a car, which is an agricultural machine. Background technique [0002] The current self-propelled harvester generally adopts a special chassis similar to that of a tractor. It is characterized in that the gearbox itself is used as the frame structure and assumes the function of the drive axle. Steering wheels only carry a fraction of the weight of the car body, and almost the entire weight of the car is placed on the driving wheels. This design is actually developed from a tractor, and its purpose is to provide a strong traction ability for towing operations. However, after being transplanted to harvesting machinery, some disadvantages appear, mainly including: most of the weight of the vehicle body is carried by the driving wheel, and the pressure on the ground is too large, which is not conducive to the protection of the cultivated land surface; Traction, so the ability to grip the gro...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): A01D67/00A01D69/06B62D63/02

Inventor 于政道

Owner 于政道

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com