Surface cleaning apparatus

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

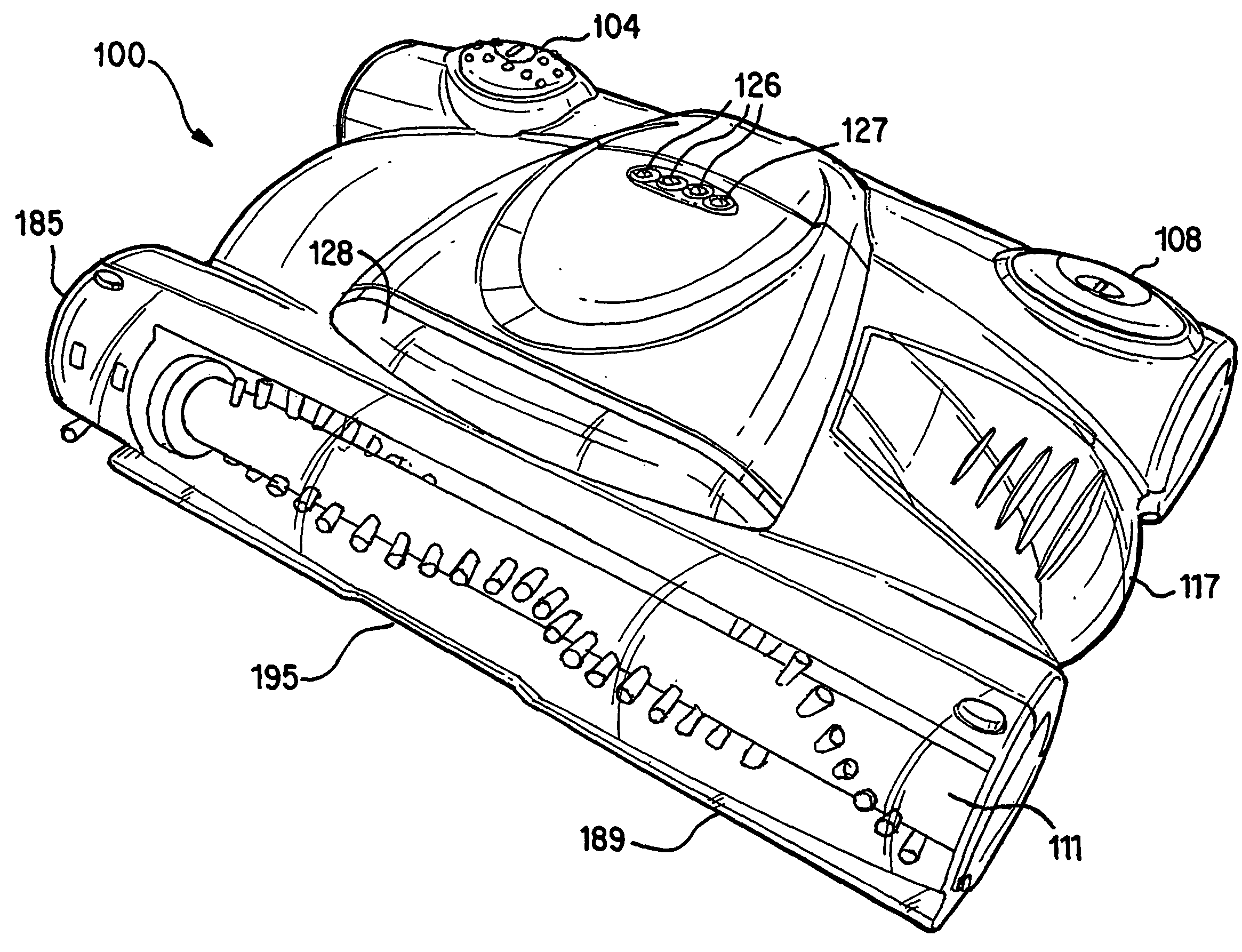

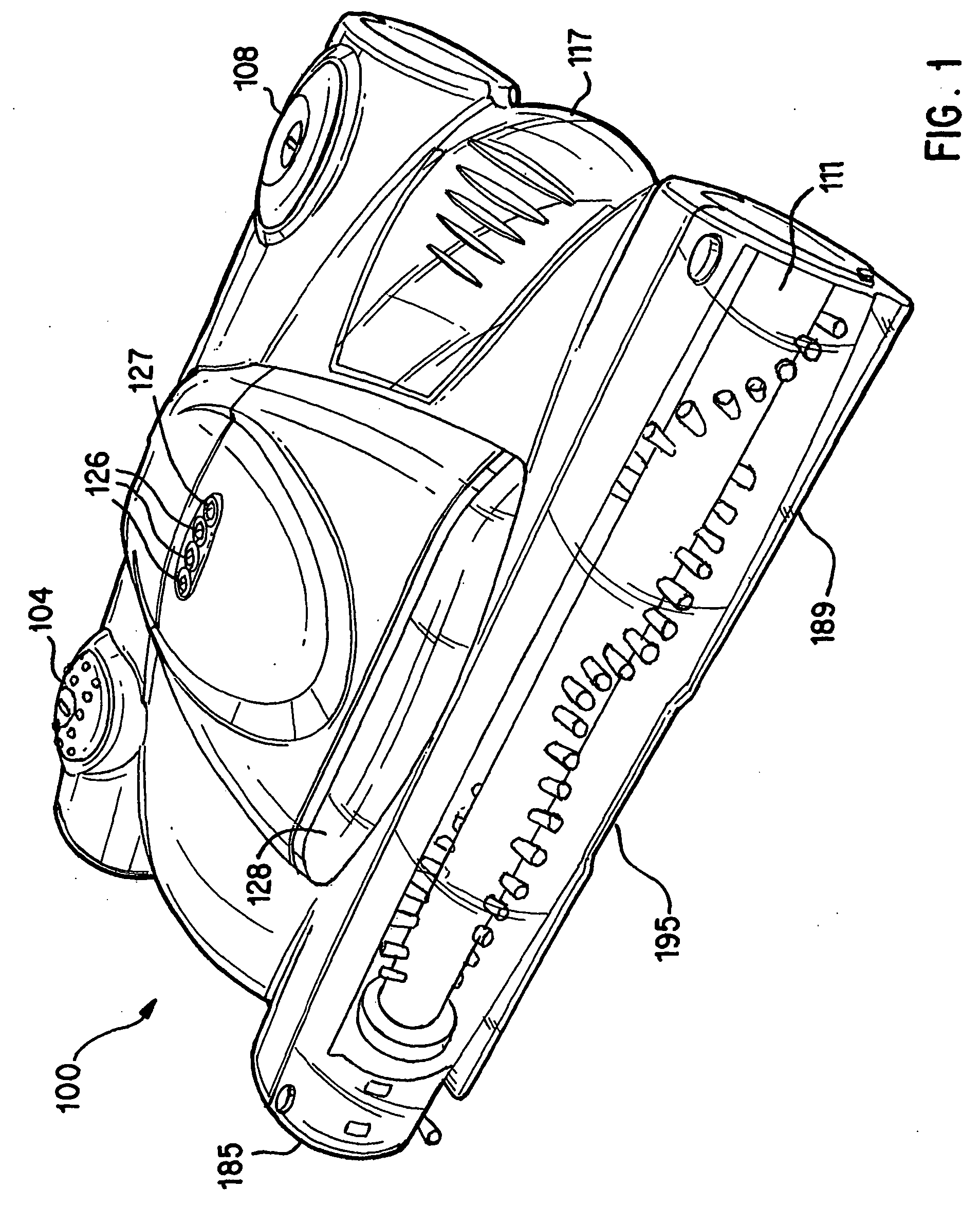

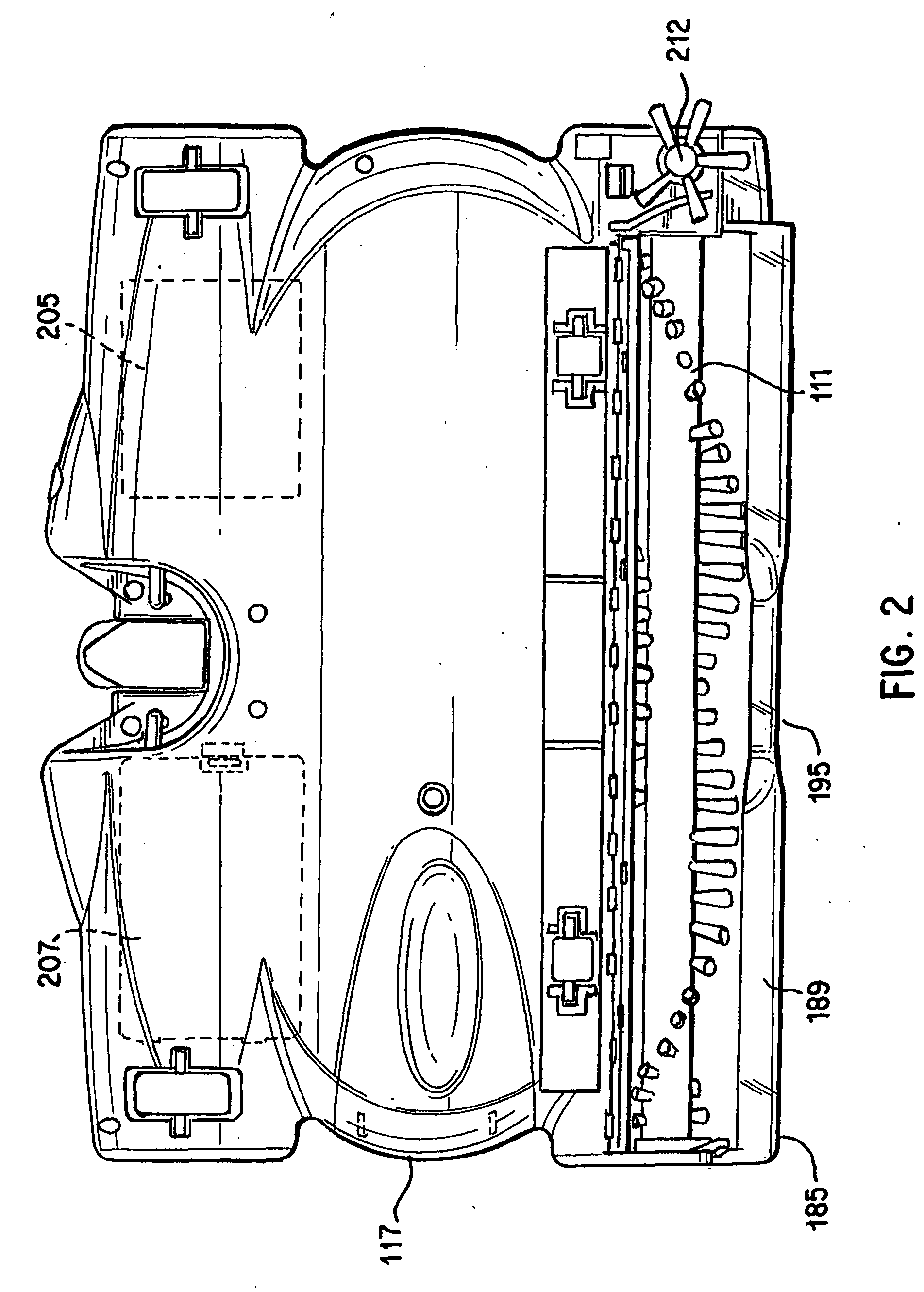

[0017] Brush rotational speed can directly impact the cleaning efficiency of a surface cleaning apparatus. Heavier or denser objects can often be collected more effectively by a cleaning apparatus having a higher rotational speed for the brush. By contrast, lower density objects or particles that have a relatively large surface area may be easier to collect using a cleaning apparatus with a lower rotational speed. The lower rotational speed will generate less air movement, thus reducing the chances that the low density object or particle will be moved away from the brush by air currents rather than being captured by the cleaning apparatus.

[0018] This invention provides a sweeper with a brush having an adjustable rotational speed. In various embodiments, the sweeper can be set to one of a plurality of brush rotational speeds. For example, in an embodiment the sweeper can have at least 2 discrete brush rotational speeds, and preferably at least 3 discrete brush rotational speeds. In ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com