Pavement marking remover with/for skid steer tractor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

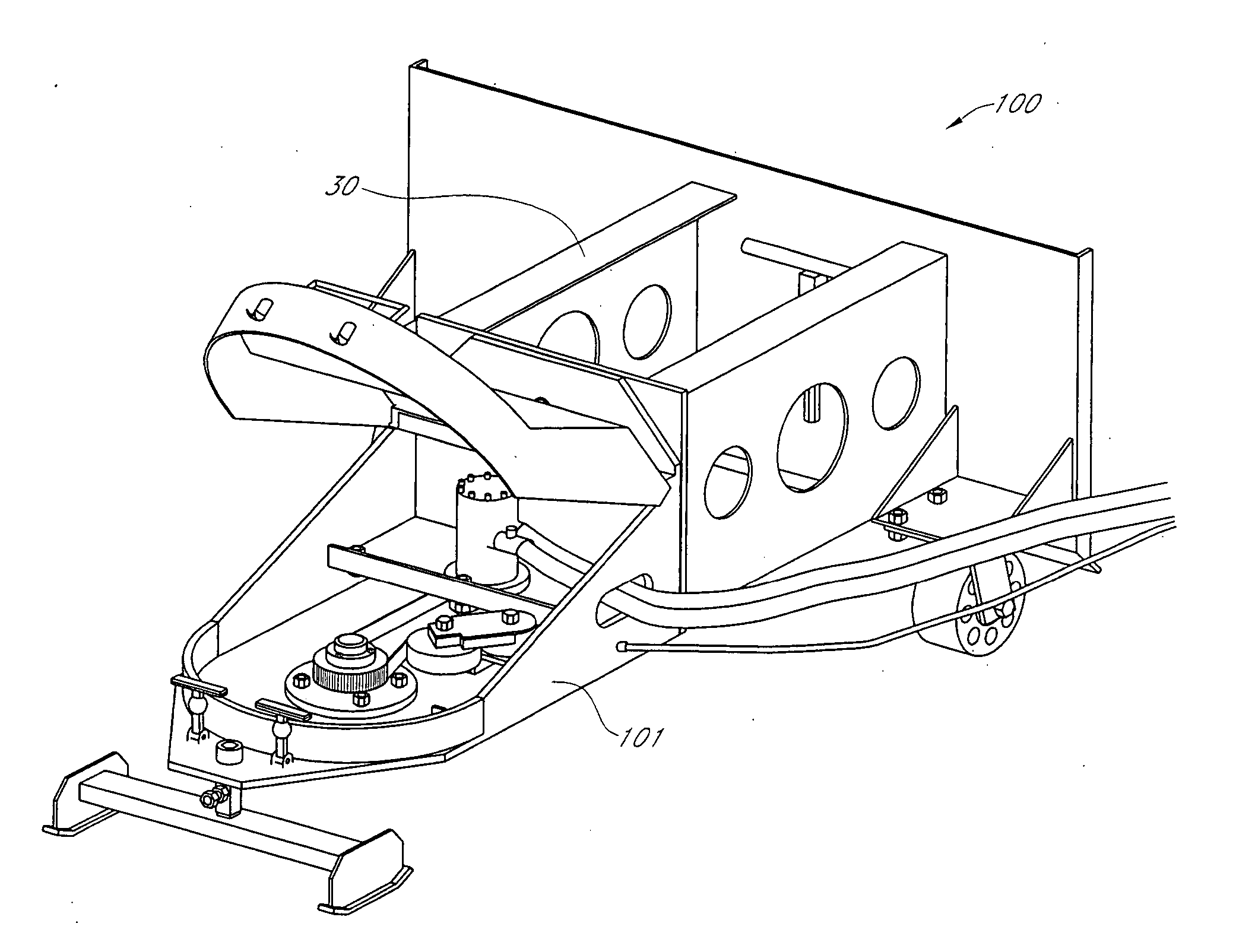

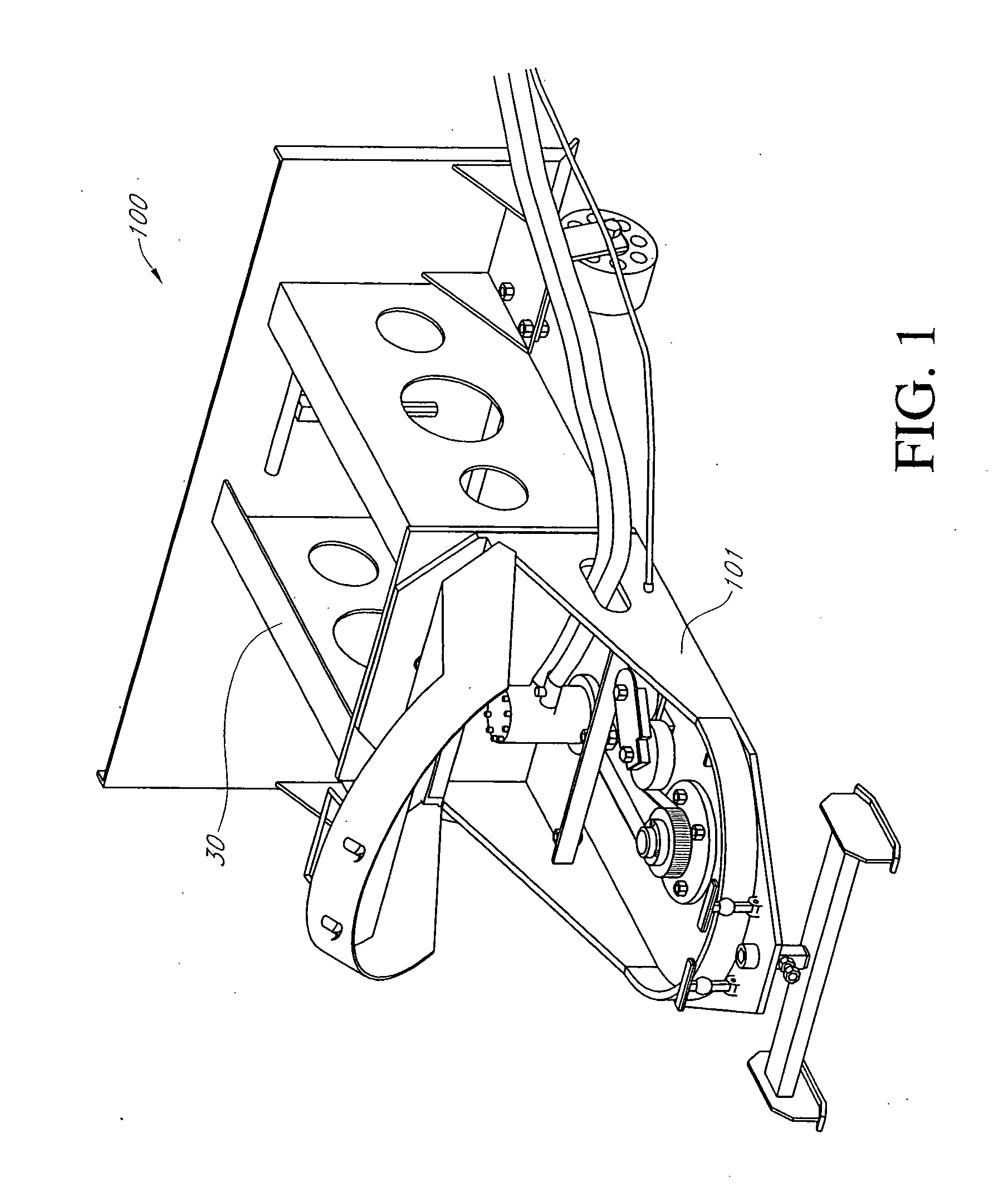

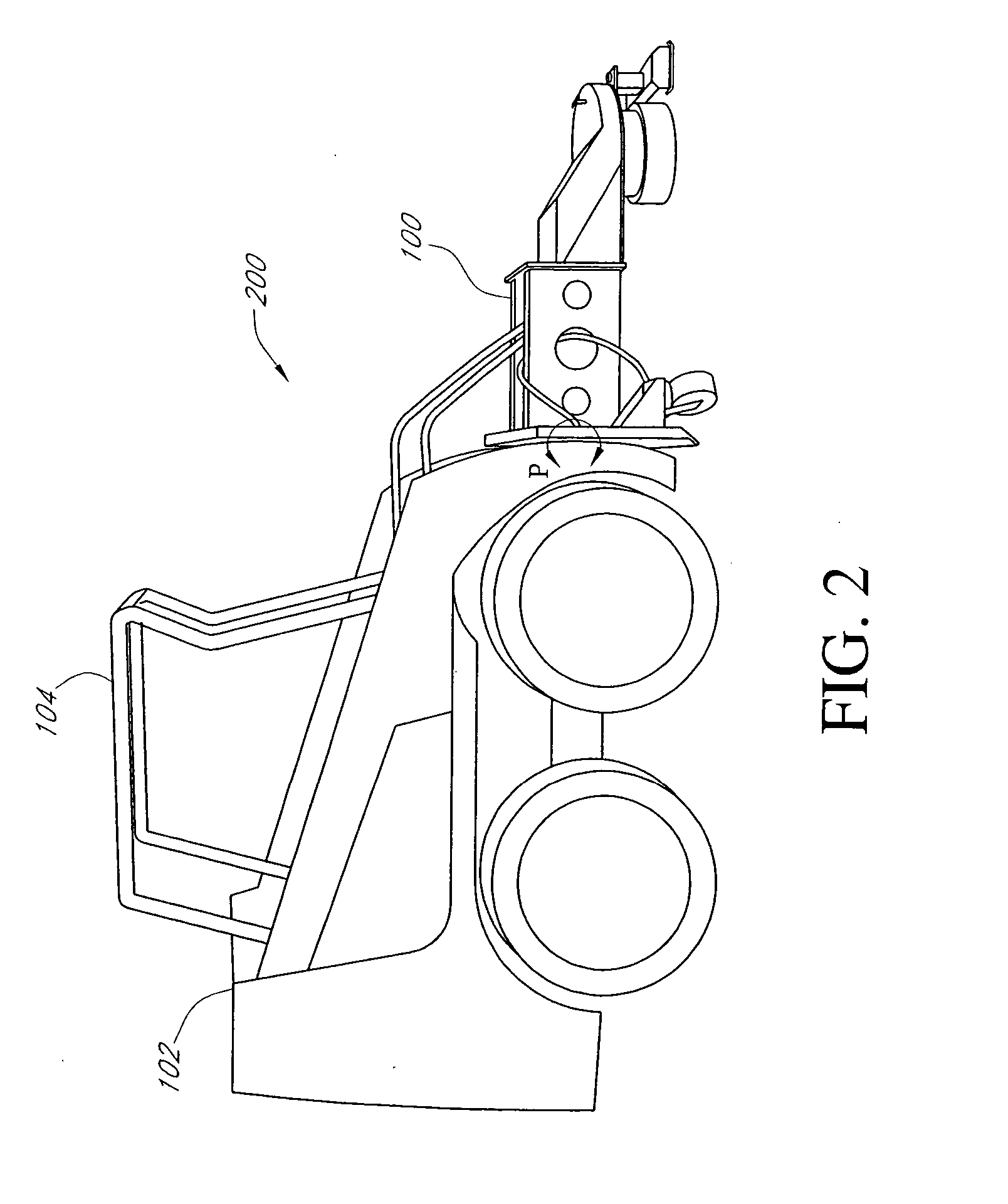

[0022] Reference will now be made to the drawings wherein like reference designators refer to like parts throughout. FIG. 1 is a perspective view of one embodiment of a pavement marking removal attachment 100 which is configured to be attached to a motor vehicle 102 (FIGS. 2-5), such as a wheeled or tracked skid steer tractor to define a pavement marking removal system 200. The motor vehicle 102 provides both motive power to move the vehicle itself and any ancillary equipment as well as operative power which can be utilized to power ancillary equipment. The motor vehicle 102 includes an operator enclosure 104 such that a user of the system 200 is provided with improved protection against hazards such as falling objects or passing traffic. The attachment 100 receives operating power from and is propelled by the motor vehicle 102 in such a manner as to remove an upper surface from pavement to remove markings which have been placed on the pavement, as well as to condition the pavement ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com