Animal litter

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

examples

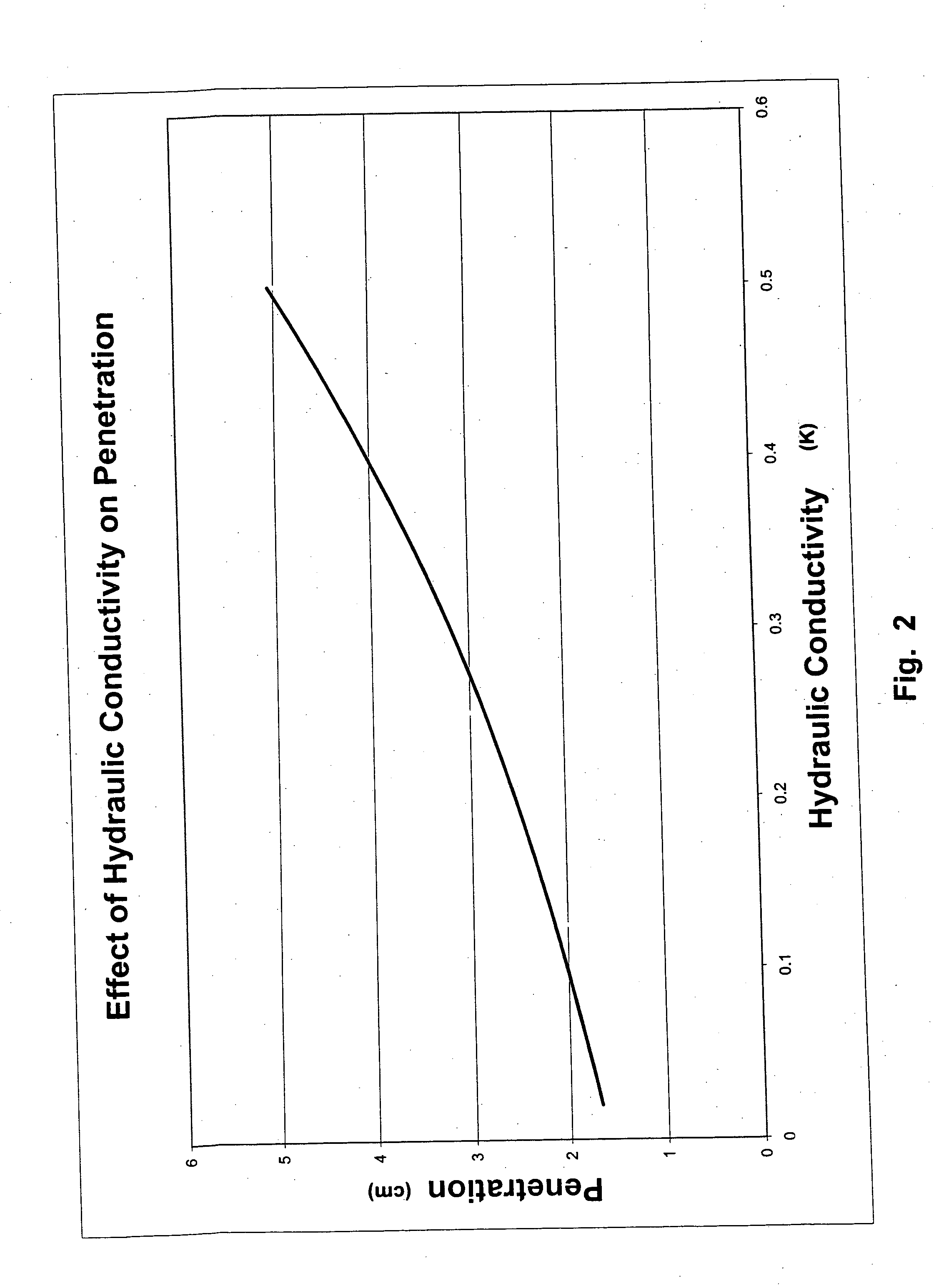

[0062] Various samples of litter compositions of the invention were prepared and investigated to determine the following characteristics: (i) agglomerate or clump strength, (ii) hydraulic conductivity, (iii) urine penetration, (iv) clump aspect ratio, (v) sensory perception, (vi) colorimetry, and (vii) and dynamic absorption (measured against bulk density and particle size). The results of the investigation are set forth below.

Clump Strength

[0063] In addition to odor control, agglomerate or clump strength is a significant performance characteristic of a silica gel based litter composition. To investigate clump strength of the litter composition(s), clumps were produced using actual feline urine. The clumps were first weighed, shaken on a coarse screen, and measured for weight loss. Clump strength was thus the percentage of the remaining litter after shaking of the clump; a clump strength of 100% indicating that none of the material fell away from the urine clump, and a clump stre...

examples of embodiments

VI. Examples of Embodiments

[0096] Disclosed herein are silica gel litters with size distributions ranging from 0.15-4 mm. One embodiment comprises at least 90% of the silica gel particles being in the 1-2 mm in size. A further embodiment comprises silica gel particles in the size range between 1-4 mm wherein the mean particle size is between 1-2 mm. A further embodiment comprises silica gel particles in the size range between 1-2 mm wherein the mean particle size is between 1-1.5 mm. In another embodiment, the silica gel material has a mean particle size between 1-4 mm. Fixing agents, antibacterial agents, colorants, fragrances and supplemental absorbent materials may be added as discussed above. The silica gel particles may comprise type A, B, C, or macroporous silica gel and mixtures thereof.

[0097] Table VII depicts one mode of the invention where amorphous silica gel was treated with a color preblend. The preblend was an aqueous solution having up to 5% of a long polymer dye to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com