Compressor

a compressor and motor technology, applied in the direction of machines/engines, rotary/oscillating piston pump components, liquid fuel engines, etc., can solve the problems of deteriorating the heat exchange efficiency, affecting the efficiency of the refrigeration cycle itself, and insufficient lubrication of the mechanical sliding portion such as the compressor mechanism in the housing, so as to achieve efficient separation of lubricant oil and reduce the effect of deterioration of heat exchange efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

[0029] Embodiments of a compressor according to the present invention will be explained with reference to the drawings. Technical elements explained in the following embodiments can be employed in various combinations unless such combinations violate the purpose of the invention.

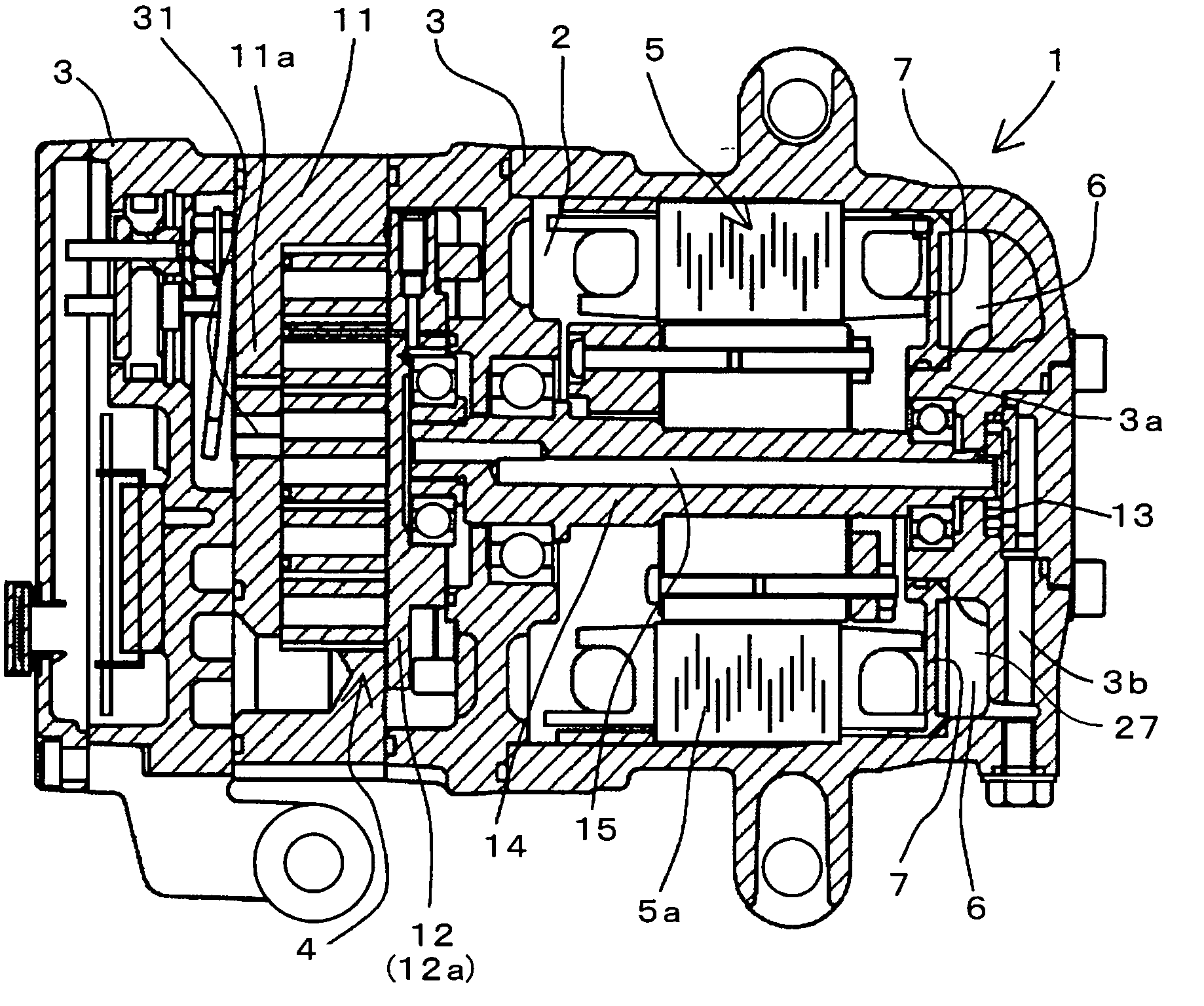

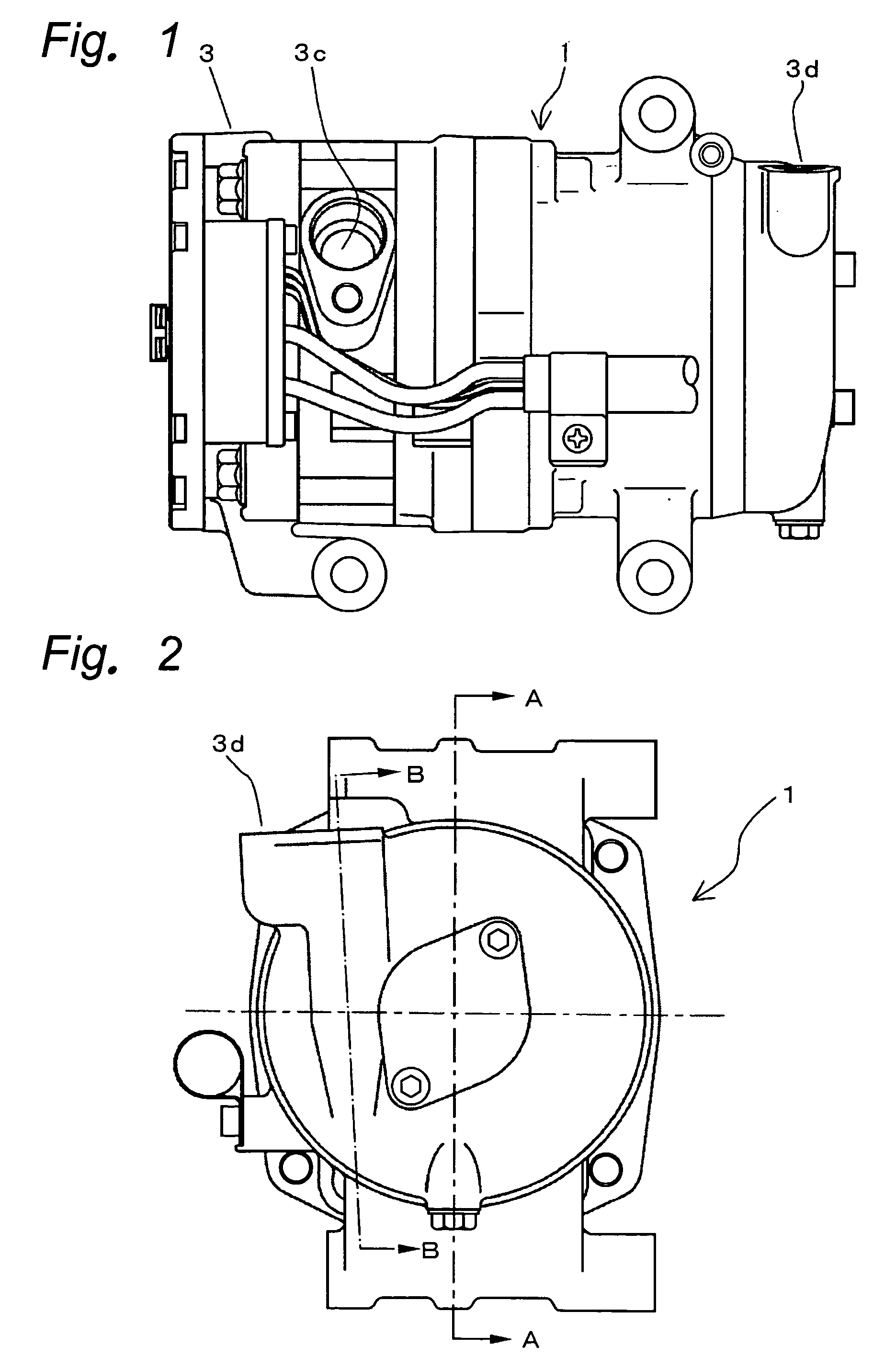

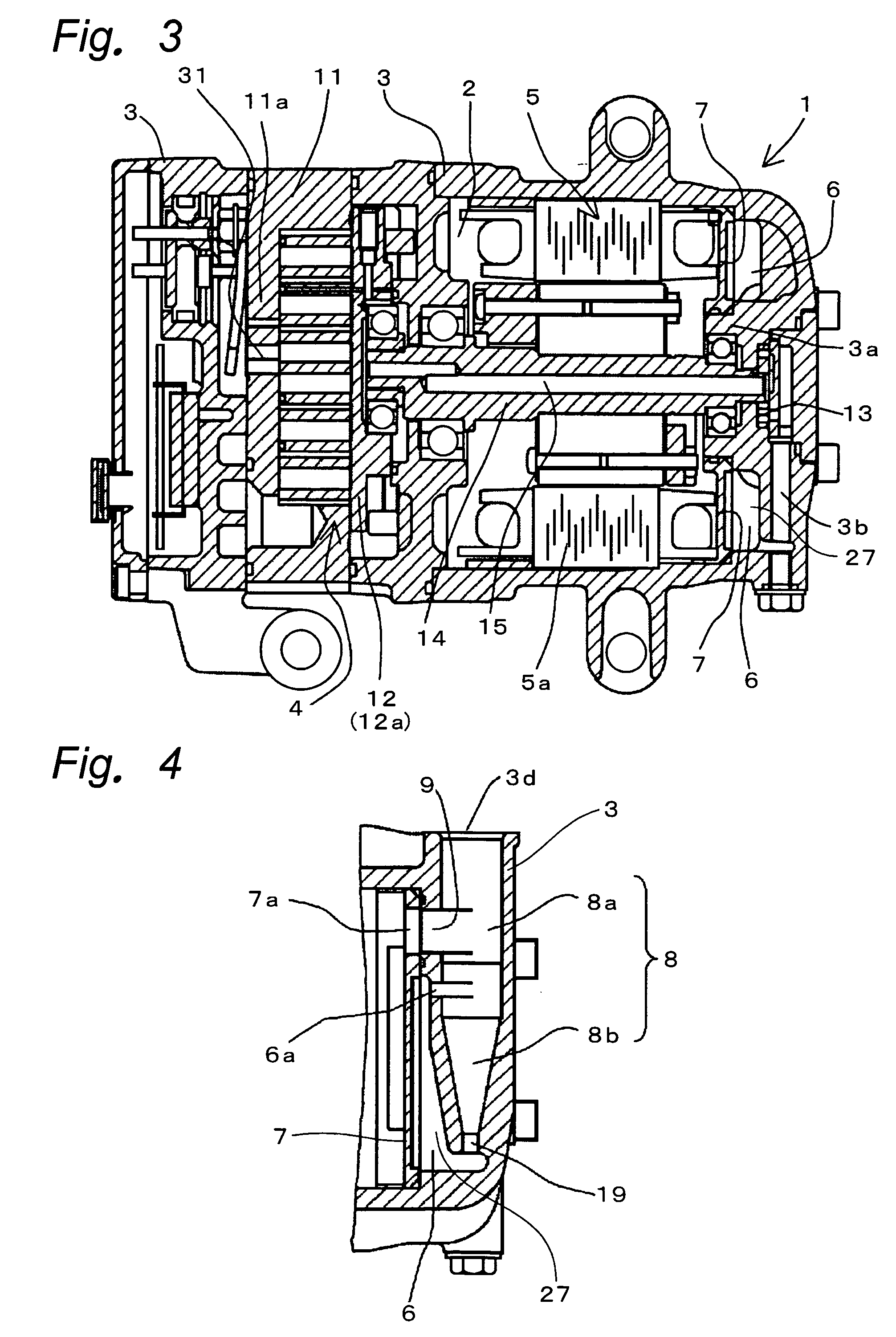

[0030]FIG. 1 is a front view of an outward appearance of a compressor according to a first embodiment of the present invention, FIG. 2 is a right side view of the outward appearance of the compressor shown in FIG. 1, FIG. 3 is a sectional view of the compressor shown in FIG. 2 taken along the line A-A, and FIG. 4 is a sectional view of the compressor shown in FIG. 2 taken along the line B-B, and FIG. 4 shows a cross section of a separation chamber in which lubricant oil included in a compressed refrigerant is separated.

[0031] The present invention is applied to a so-called horizontal type motor-incorporated compressor of the embodiment shown in the drawings which is disposed such that a rotation center axi...

second embodiment

[0043]FIG. 5 is a sectional view of a compressor according to a second embodiment of the present invention.

[0044]FIG. 5 shows one example of a horizontal type electric compressor which is disposed horizontally using mounting legs 20 provided around a body of the compressor 1.

[0045] The compressor 1 of the second embodiment has the housing 3 in which the compressor mechanism 4 and the motor 5 for driving the compressor mechanism 4 are accommodated. The lubricant oil 27 used for lubricating sliding portions including the compressor mechanism 4 is stored in the oil-reservoir chamber 6. The motor 5 is driven by a motor drive circuit (not shown). Gas refrigerant is used as the refrigerant. The lubricant oil 27 is used for lubricating the sliding portions and also used for sealing the sliding portions of the compressor mechanism 4. Lubricant oil having compatibility with respect to the refrigerant is used as the lubricant oil 27.

[0046] The compressor is not limited to the compressor 1 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com